/MAT/LAW2 (PLAS_JOHNS)

Block Format Keyword This law represents an isotropic elasto-plastic material using the Johnson-Cook material model.

This model expresses material stress as a function of strain, strain rate and temperature. A built-in failure criterion based on the maximum plastic strain is available.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW2/mat_ID/unit_ID or /MAT/PLAS_JOHNS/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | Iflag | ||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| a | b | n | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| UTS | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| c | ICC | Fsmooth | Fcut | Chard | |||||

| m | Tmelt | Tr | |||||||

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier (Integer, maximum 10 digits) |

|

| mat_title | Material title (Character, maximum 100 characters) |

|

| Initial density. (Real) |

||

| E | Young's modulus. (Real) |

|

| Poisson's ratio. (Real) |

||

| Iflag | Input type flag. 3

(Integer) |

|

| a | Yield stress. 2 (Real) |

|

| b | Plastic hardening parameter b. (Real) |

|

| n | Plastic hardening exponent n. 6

Default = 1.0 (Real) |

|

| Failure plastic strain. Default = 1030 (Real) |

||

| Maximum stress. Default = 1030 (Real) |

||

| Yield stress. (Real) |

||

| UTS | Ultimate tensile stress (engineering

stress). Input

. (Real) |

|

| Engineering strain at

UTS. Default = 1.0 (Real) |

||

| c | Strain rate coefficient

.

Default = 0.00 (Real) |

|

| Reference strain rate. If , no strain rate effect. (Real) |

||

| ICC | Strain rate computation flag. 9

(Integer) |

|

| Fsmooth | Strain rate smoothing flag.

(Integer) |

|

| Fcut | Cutoff frequency for strain rate smoothing. Only available for shell and solid

elements, Appendix: Filtering. Default = 1030 (Real) |

|

| Chard | Hardening coefficient (unloading).

(Real) |

|

| m | Temperature exponent. 13 Default = 1.00 (Real) |

|

| Tmelt | Melting temperature.

Default = 1030 (Real) |

|

| Specific heat per unit volume. 11 (Real) |

||

| Tr | Reference temperature. 11 Default = 298 K (Real) |

Example (Classic Parameter Input)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/PLAS_JOHNS/1/1

Steel

# RHO_I

7.8E-9

# E Nu Iflag

210000 .3 0

# a b n EPS_max SIG_max0

270 450.0 0.6 0 0

# c EPS_DOT_0 ICC Fsmooth F_cut Chard

0 0 0 0 0 0

# m T_melt rhoC_p T_r

0 0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Example (Simplified Input - Experimental Data)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/PLAS_JOHNS/1/1

Steel (use ultimate tensile stress(UTS) and engineering strain )

# RHO_I

7.8E-9

# E Nu Iflag

210000 .3 1

# SIG_y UTS EPS_UTS EPS_max SIG_max0

270 362.8 0.2885 0 0

# c EPS_DOT_0 ICC Fsmooth F_cut Chard

0 0 0 0 0 0

# m T_melt rhoC_p T_r

0 0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- This is an elasto-plastic material model that includes strain rate and temperature effects with true stress and strain output.

- In this model the material behaves as a

linear-elastic material when the equivalent stress is lower than the plastic yield stress.

For higher stress values, the material behavior is plastic, and the true stress is

calculated as:

(1) Where,(2) Where,- Plastic strain

- Strain rate

- Temperature

- Tr

- Ambient temperature

- Tmelt

- Melting temperature

- If Iflag=0, the Johnson-Cook equation parameters a, b, and n values are entered.

If Iflag=1, experimental engineering stress and stain data can be entered for , UTS and and the parameters a, b and n are calculated and printed in the Starter output file. If the a, b and n parameters cannot be automatically fit, then a Starter warning message will contain important information about changes to the material input.

- The plastic yield stress should always be greater than zero. To model pure elastic behavior, the plastic yield stress will be set to 1030.

- When

reaches the value of

in one integration point, then based on the element type:

- Shell elements: The corresponding shell element is deleted.

- Solid elements: The deviatoric stress of the corresponding integral point is permanently set to 0; however, the solid element is not deleted.

- The plastic hardening exponent, n must be less than or equal to 1.

- The strain rate has no effect on truss elements.

- To eliminate the effect of the strain rate, you can either set the value of c equal to 0 or the reference strain rate ( ) can be set equal to 1030. There is no effect of strain rate when is less than .

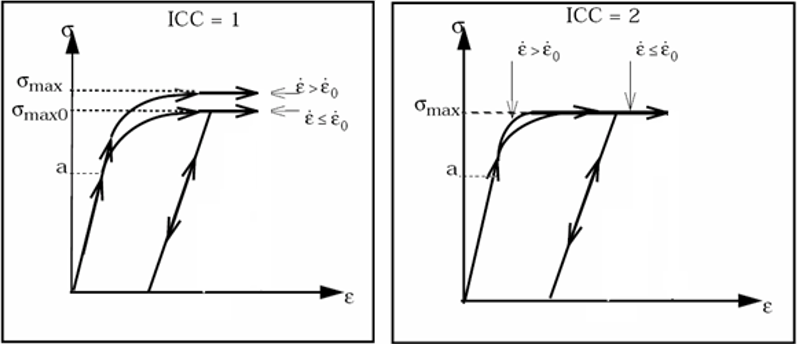

- The ICC flag defines the effect of strain

rate on the maximum material stress

. Figure 1 shows the value of for

the corresponding ICC flag.

Figure 1.

Figure 1. - There is no effect of temperature on trusses and beams.

- The temperature is constant ( ), if .

- Adiabatic conditions are assumed for

thermal simulations with initial temperature equal to reference temperature (Tr) and:

(3) Where, Eint is the internal deformation energy.

- The strain rate coefficient, c and reference strain rate must be defined to include thermal effects.

- When /HEAT/MAT (with Iform=1) references this material model, the values of Tr and defined in this card will be overwritten by the corresponding and defined in /HEAT/MAT.

- When the temperature is not initialized using /HEAT/MAT or /INITEMP, the reference temperature (Tr) is also the initial temperature.

- The hardening coefficient is used to describe the hardening model (during unloading). The values of the hardening coefficient should be between 0 and 1.