In Radioss material laws LAW32, LAW43, LAW72, LAW73,

LAW74, LAW78 and LAW93 use HILL criteria.

HILL Criteria

The typical HILL criteria is:

3D equivalent HILL stress:(8)

f =

F

(

σ

y y

−

σ

z z

)

2

+ G

(

σ

z z

−

σ

x x

)

2

+ H

(

σ

x x

−

σ

y y

)

2

+ 2 L

σ

y z

2

+ 2 M

σ

z x

2

+ 2 N

σ

x y

2

=

(

G + H

)

︸

σ

x x

2

+

(

F + H

)

︸

σ

y y

2

+

(

F + G

)

︸

σ

z z

2

−

2 H

︸

σ

x x

σ

y y

−

2 F

︸

σ

y y

σ

z z

−

2 G

︸

σ

z z

σ

x x

+

2 L

︸

σ

y z

2

+

2 M

︸

σ

z x

2

+

2 N

︸

σ

x y

2

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqGqFfpeea0xe9vq=Jb9

vqpeea0xd9q8qiYRWxGi6xij=hbba9q8aq0=yq=He9q8qiLsFr0=vr

0=vr0db8meaabaqaciGacaGaaeqabaWaaeaaeaaakqaabeqaaiaadA

gacqGH9aqpdaGcaaqaaiaadAeadaqadiqaaiabeo8aZnaaBaaaleaa

caWG5bGaamyEaaqabaGccqGHsislcqaHdpWCdaWgaaWcbaGaamOEai

aadQhaaeqaaaGccaGLOaGaayzkaaWaaWbaaSqabeaacaaIYaaaaOGa

ey4kaSIaam4ramaabmGabaGaeq4Wdm3aaSbaaSqaaiaadQhacaWG6b

aabeaakiabgkHiTiabeo8aZnaaBaaaleaacaWG4bGaamiEaaqabaaa

kiaawIcacaGLPaaadaahaaWcbeqaaiaaikdaaaGccqGHRaWkcaWGib

WaaeWaceaacqaHdpWCdaWgaaWcbaGaamiEaiaadIhaaeqaaOGaeyOe

I0Iaeq4Wdm3aaSbaaSqaaiaadMhacaWG5baabeaaaOGaayjkaiaawM

caamaaCaaaleqabaGaaGOmaaaakiabgUcaRiaaygW7caaIYaGaamit

aiabeo8aZnaaDaaaleaacaWG5bGaamOEaaqaaiaaikdaaaGccqGHRa

WkcaaIYaGaamytaiabeo8aZnaaDaaaleaacaWG6bGaamiEaaqaaiaa

ikdaaaGccqGHRaWkcaaIYaGaamOtaiabeo8aZnaaDaaaleaacaWG4b

GaamyEaaqaaiaaikdaaaaabeaaaOqaaiaabccacaqGGaGaaeiiaiaa

b2dadaGcaaqaamaayaaabaWaaeWaaeaacaWGhbGaey4kaSIaamisaa

GaayjkaiaawMcaaaWcbaaakiaawIJ=aiabeo8aZnaaDaaaleaacaWG

4bGaamiEaaqaaiaaikdaaaGccqGHRaWkdaagaaqaamaabmaabaGaam

OraiabgUcaRiaadIeaaiaawIcacaGLPaaaaSqaaaGccaGL44pacqaH

dpWCdaqhaaWcbaGaamyEaiaadMhaaeaacaaIYaaaaOGaey4kaSYaaG

baaeaadaqadaqaaiaadAeacqGHRaWkcaWGhbaacaGLOaGaayzkaaaa

leaaaOGaayjo+dGaeq4Wdm3aa0baaSqaaiaadQhacaWG6baabaGaaG

OmaaaakiabgkHiTmaayaaabaGaaGOmaiaadIeaaSqaaaGccaGL44pa

cqaHdpWCdaWgaaWcbaGaamiEaiaadIhaaeqaaOGaeq4Wdm3aaSbaaS

qaaiaadMhacaWG5baabeaakiabgkHiTmaayaaabaGaaGOmaiaadAea

aSqaaaGccaGL44pacqaHdpWCdaWgaaWcbaGaamyEaiaadMhaaeqaaO

Gaeq4Wdm3aaSbaaSqaaiaadQhacaWG6baabeaakiabgkHiTmaayaaa

baGaaGOmaiaadEeaaSqaaaGccaGL44pacqaHdpWCdaWgaaWcbaGaam

OEaiaadQhaaeqaaOGaeq4Wdm3aaSbaaSqaaiaadIhacaWG4baabeaa

kiabgUcaRmaayaaabaGaaGzaVlaaikdacaWGmbaaleaaaOGaayjo+d

Gaeq4Wdm3aa0baaSqaaiaadMhacaWG6baabaGaaGOmaaaakiabgUca

RmaayaaabaGaaGOmaiaad2eaaSqaaaGccaGL44pacqaHdpWCdaqhaa

WcbaGaamOEaiaadIhaaeaacaaIYaaaaOGaey4kaSYaaGbaaeaacaaI

YaGaamOtaaWcbaaakiaawIJ=aiabeo8aZnaaDaaaleaacaWG4bGaam

yEaaqaaiaaikdaaaaabeaaaaaa@DD25@

Shell element:(9)

f

=

F

σ

y

y

2

+

G

σ

x

x

2

+

H

(

σ

x

x

−

σ

y

y

)

2

+

2

N

σ

x

y

2

=

(

G

+

H

)

︸

σ

x

x

2

+

(

F

+

H

)

︸

σ

y

y

2

−

2

H

︸

σ

x

x

σ

y

y

+

2

N

︸

σ

x

y

2

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqGqFfpeea0xe9vq=Jb9

vqpeea0xd9q8qiYRWxGi6xij=hbba9q8aq0=yq=He9q8qiLsFr0=vr

0=vr0db8meaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGMbGaey

ypa0ZaaOaaaeaacaWGgbGaeq4Wdm3aa0baaSqaaiaadMhacaWG5baa

baGaaGOmaaaakiabgUcaRiaadEeacqaHdpWCdaqhaaWcbaGaamiEai

aadIhaaeaacaaIYaaaaOGaey4kaSIaamisamaabmGabaGaeq4Wdm3a

aSbaaSqaaiaadIhacaWG4baabeaakiabgkHiTiabeo8aZnaaBaaale

aacaWG5bGaamyEaaqabaaakiaawIcacaGLPaaadaahaaWcbeqaaiaa

ikdaaaGccqGHRaWkcaaIYaGaamOtaiabeo8aZnaaDaaaleaacaWG4b

GaamyEaaqaaiaaikdaaaaabeaakiabg2da9maakaaabaWaaGbaaeaa

daqadaqaaiaadEeacqGHRaWkcaWGibaacaGLOaGaayzkaaaaleaaaO

Gaayjo+dGaeq4Wdm3aa0baaSqaaiaadIhacaWG4baabaGaaGOmaaaa

kiabgUcaRmaayaaabaWaaeWaaeaacaWGgbGaey4kaSIaamisaaGaay

jkaiaawMcaaaWcbaaakiaawIJ=aiabeo8aZnaaDaaaleaacaWG5bGa

amyEaaqaaiaaikdaaaGccqGHsisldaagaaqaaiaaikdacaWGibaale

aaaOGaayjo+dGaeq4Wdm3aaSbaaSqaaiaadIhacaWG4baabeaakiab

eo8aZnaaBaaaleaacaWG5bGaamyEaaqabaGccqGHRaWkdaagaaqaai

aaikdacaWGobaaleaaaOGaayjo+dGaeq4Wdm3aa0baaSqaaiaadIha

caWG5baabaGaaGOmaaaaaeqaaaaa@863E@

Where,

F

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOraaaa@36C1@

G

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOraaaa@36C1@

H

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOraaaa@36C1@

L

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOraaaa@36C1@

M

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOraaaa@36C1@

N

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOraaaa@36C1@

F

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOraaaa@36C1@

G

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOraaaa@36C1@

H

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOraaaa@36C1@

N

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOraaaa@36C1@

In LAW78, the HILL criteria is:

(10)

φ

(

A

)

=

1

︸

G

+

H

⋅

A

x

x

2

−

2

r

0

1

+

r

0

︸

2

H

A

x

x

A

y

y

+

r

0

(

1

+

r

90

)

r

90

(

1

+

r

0

)

︸

F

+

H

A

y

y

2

+

r

0

+

r

90

r

90

(

1

+

r

0

)

(

2

r

45

+

1

)

︸

2

N

A

x

y

2

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacqaHgpGAca

GGOaGaamyqaiaacMcacqGH9aqpdaagaaqaaiaaigdaaSqaaiaadEea

cqGHRaWkcaWGibaakiaawIJ=aiabgwSixlaadgeadaqhaaWcbaGaam

iEaiaadIhaaeaacaaIYaaaaOGaeyOeI0YaaGbaaeaadaWcaaqaaiaa

ikdacaWGYbWaaSbaaSqaaiaaicdaaeqaaaGcbaGaaGymaiabgUcaRi

aadkhadaWgaaWcbaGaaGimaaqabaaaaaqaaiaaikdacaWGibaakiaa

wIJ=aiaadgeadaWgaaWcbaGaamiEaiaadIhaaeqaaOGaamyqamaaBa

aaleaacaWG5bGaamyEaaqabaGccqGHRaWkdaagaaqaamaalaaabaGa

amOCamaaBaaaleaacaaIWaaabeaakmaabmaabaGaaGymaiabgUcaRi

aadkhadaWgaaWcbaGaaGyoaiaaicdaaeqaaaGccaGLOaGaayzkaaaa

baGaamOCamaaBaaaleaacaaI5aGaaGimaaqabaGcdaqadaqaaiaaig

dacqGHRaWkcaWGYbWaaSbaaSqaaiaaicdaaeqaaaGccaGLOaGaayzk

aaaaaaWcbaGaamOraiabgUcaRiaadIeaaOGaayjo+dGaamyqamaaDa

aaleaacaWG5bGaamyEaaqaaiaaikdaaaGccqGHRaWkdaagaaqaamaa

laaabaGaamOCamaaBaaaleaacaaIWaaabeaakiabgUcaRiaadkhada

WgaaWcbaGaaGyoaiaaicdaaeqaaaGcbaGaamOCamaaBaaaleaacaaI

5aGaaGimaaqabaGcdaqadaqaaiaaigdacqGHRaWkcaWGYbWaaSbaaS

qaaiaaicdaaeqaaaGccaGLOaGaayzkaaaaamaabmaabaGaaGOmaiaa

dkhadaWgaaWcbaGaaGinaiaaiwdaaeqaaOGaey4kaSIaaGymaaGaay

jkaiaawMcaaaWcbaGaaGOmaiaad6eaaOGaayjo+dGaamyqamaaDaaa

leaacaWG4bGaamyEaaqaaiaaikdaaaaaaa@8B69@

There are two ways to determine HILL parameters

by using Lankford parameters.

Strain ratio

r

00

,

r

45

,

r

90

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOCamaaBa

aaleaacaaIWaGaaGimaaqabaGccaGGSaGaamOCamaaBaaaleaacaaI

0aGaaGynaaqabaGccaGGSaGaamOCamaaBaaaleaacaaI5aGaaGimaa

qabaaaaa@3F42@

Yield stress ratio

R

11

,

R

22

,

R

33

,

R

12

,

R

13

,

R

23

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOuamaaBa

aaleaacaaIXaGaaGymaaqabaGccaGGSaGaamOuamaaBaaaleaacaaI

YaGaaGOmaaqabaGccaGGSaGaamOuamaaBaaaleaacaaIZaGaaG4maa

qabaGccaGGSaGaamOuamaaBaaaleaacaaIXaGaaGOmaaqabaGccaGG

SaGaamOuamaaBaaaleaacaaIXaGaaG4maaqabaGccaGGSaGaamOuam

aaBaaaleaacaaIYaGaaG4maaqabaaaaa@487B@

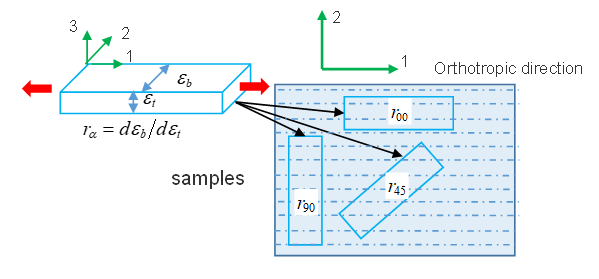

Strain Ratio

The Lankford parameters

r

α

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaqaaaaaaaaa

WdbiaadkhapaWaaSbaaSqaa8qacqaHXoqya8aabeaaaaa@396F@

is the ratio of plastic strain in plane and plastic

strain in thickness direction

ε

33

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaqaaaaaaaaa

Wdbiabew7aL9aadaWgaaWcbaWdbiaaiodacaaIZaaapaqabaaaaa@39FA@

.

(11)

r

α

=

d

ε

α

+

π

/

2

d

ε

33

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaqaaaaaaaaa

WdbiaadkhapaWaaSbaaSqaa8qacqaHXoqya8aabeaak8qacqGH9aqp

daWcaaWdaeaapeGaamizaiabew7aL9aadaWgaaWcbaWdbiabeg7aHj

abgUcaRiabec8aWjaac+cacaaIYaaapaqabaaakeaapeGaamizaiab

ew7aL9aadaWgaaWcbaWdbiaaiodacaaIZaaapaqabaaaaaaa@47D3@

Where,

α

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaaleaaqaaaaaaaaa

Wdbiabeg7aHbaa@381F@

r

α

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaqaaaaaaaaa

WdbiaadkhapaWaaSbaaSqaa8qacqaHXoqya8aabeaaaaa@396F@

r

00

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOCamaaBa

aaleaacaaIWaGaaGimaaqabaaaaa@388E@

r

90

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOCamaaBa

aaleaacaaI5aGaaGimaaqabaaaaa@3897@

The strain ratio is the strain in width direction of sample to strain in thickness

direction of sample.

Figure 10.

In this case, the HILL parameters are:

(12)

F

=

r

00

r

90

(

r

00

+

1

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGgbGaey

ypa0ZaaSaaaeaacaWGYbWaaSbaaSqaaiaaicdacaaIWaaabeaaaOqa

aiaadkhadaWgaaWcbaGaaGyoaiaaicdaaeqaaOGaaiikaiaadkhada

WgaaWcbaGaaGimaiaaicdaaeqaaOGaey4kaSIaaGymaiaacMcaaaaa aa@4322@

(13)

G

=

1

(

r

00

+

1

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGhbGaey

ypa0ZaaSaaaeaacaaIXaaabaGaaiikaiaadkhadaWgaaWcbaGaaGim

aiaaicdaaeqaaOGaey4kaSIaaGymaiaacMcaaaaaaa@3E93@

(14)

H

=

r

00

(

r

00

+

1

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGibGaey

ypa0ZaaSaaaeaacaWGYbWaaSbaaSqaaiaaicdacaaIWaaabeaaaOqa

aiaacIcacaWGYbWaaSbaaSqaaiaaicdacaaIWaaabeaakiabgUcaRi

aaigdacaGGPaaaaaaa@407A@

(15)

N

=

(

1

+

2

r

45

)

(

r

00

+

r

90

)

2

r

90

(

r

00

+

1

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGobGaey

ypa0ZaaSaaaeaacaGGOaGaaGymaiabgUcaRiaaikdacaWGYbWaaSba

aSqaaiaaisdacaaI1aaabeaakiaacMcacaGGOaGaamOCamaaBaaale

aacaaIWaGaaGimaaqabaGccqGHRaWkcaWGYbWaaSbaaSqaaiaaiMda

caaIWaaabeaakiaacMcaaeaacaaIYaGaamOCamaaBaaaleaacaaI5a

GaaGimaaqabaGccaGGOaGaamOCamaaBaaaleaacaaIWaGaaGimaaqa

baGccqGHRaWkcaaIXaGaaiykaaaaaaa@4F27@

Here,

G

+

H

=

1

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGhbGaey

4kaSIaamisaiabg2da9iaaigdaaaa@3A9B@

In LAW32, LAW43, and LAW73, the HILL criteria is:

(16)

σ

e

q

=

A

1

σ

1

2

+

A

2

σ

2

2

−

A

3

σ

1

σ

2

+

A

12

σ

12

2

R

=

r

00

+

2

r

45

+

r

90

4

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGsbGaey

ypa0ZaaSaaaeaacaWGYbWaaSbaaSqaaiaaicdacaaIWaaabeaakiab

gUcaRiaaikdacaWGYbWaaSbaaSqaaiaaisdacaaI1aaabeaakiabgU

caRiaadkhadaWgaaWcbaGaaGyoaiaaicdaaeqaaaGcbaGaaGinaaaa

aaa@437F@

H

=

R

1

+

R

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGibGaey

ypa0ZaaSaaaeaacaWGsbaabaGaaGymaiabgUcaRiaadkfaaaaaaa@3B8D@

A

1

=

H

(

1

+

1

r

00

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGbbWaaS

baaSqaaiaaigdaaeqaaOGaeyypa0JaamisamaabmaabaGaaGymaiab

gUcaRmaalaaabaGaaGymaaqaaiaadkhadaWgaaWcbaGaaGimaiaaic

daaeqaaaaaaOGaayjkaiaawMcaaaaa@407B@

A

2

=

H

(

1

+

1

r

90

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGbbWaaS

baaSqaaiaaikdaaeqaaOGaeyypa0JaamisamaabmaabaGaaGymaiab

gUcaRmaalaaabaGaaGymaaqaaiaadkhadaWgaaWcbaGaaGyoaiaaic

daaeqaaaaaaOGaayjkaiaawMcaaaaa@4085@

A

3

=

2

H

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGbbWaaS

baaSqaaiaaiodaaeqaaOGaeyypa0JaaGOmaiaadIeaaaa@3AA7@

A

12

=

2

H

(

r

45

+

0.5

)

(

1

r

00

+

1

r

90

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGbbWaaS

baaSqaaiaaigdacaaIYaaabeaakiabg2da9iaaikdacaWGibGaaiik

aiaadkhadaWgaaWcbaGaaGinaiaaiwdaaeqaaOGaey4kaSIaaGimai

aac6cacaaI1aGaaiykamaabmaabaWaaSaaaeaacaaIXaaabaGaamOC

amaaBaaaleaacaaIWaGaaGimaaqabaaaaOGaey4kaSYaaSaaaeaaca

aIXaaabaGaamOCamaaBaaaleaacaaI5aGaaGimaaqabaaaaaGccaGL

OaGaayzkaaaaaa@4BBD@

They all request Lankford parameter (strain ratio)

r

00

,

r

45

,

r

90

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOCamaaBa

aaleaacaaIWaGaaGimaaqabaGccaGGSaGaamOCamaaBaaaleaacaaI

0aGaaGynaaqabaGccaGGSaGaamOCamaaBaaaleaacaaI5aGaaGimaa

qabaaaaa@3F42@

A

i

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamyqamaaBa

aaleaacaWGPbaabeaaaaa@37D6@

Radioss .

Yield Stress Ratio

In LAW93, the yield stress ratio used is:

(17)

R

i

j

=

σ

i

j

σ

0

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOuamaaBa

aaleaacaWGPbGaamOAaaqabaGccqGH9aqpdaWcaaqaaiabeo8aZnaa

BaaaleaacaWGPbGaamOAaaqabaaakeaacqaHdpWCdaWgaaWcbaGaaG

imaaqabaaaaaaa@4076@

To get yield stress ratio

R

i

j

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOuamaaBa

aaleaacaWGPbGaamOAaaqabaaaaa@38D7@

, yield stress in two loading cases need to be

measured.

Yield stress

σ

11

,

σ

22

,

σ

33

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aaS

baaSqaaiaaigdacaaIXaaabeaakiaacYcacqaHdpWCdaWgaaWcbaGa

aGOmaiaaikdaaeqaaOGaaiilaiabeo8aZnaaBaaaleaacaaIZaGaaG

4maaqabaaaaa@41A0@

Yield shear stress

σ

12

,

σ

13

,

σ

23

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aaS

baaSqaaiaaigdacaaIYaaabeaakiaacYcacqaHdpWCdaWgaaWcbaGa

aGymaiaaiodaaeqaaOGaaiilaiabeo8aZnaaBaaaleaacaaIYaGaaG

4maaqabaaaaa@41A0@

In LAW93, if parameter input is used, then take initial stress parameter

σ

y

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aaS

baaSqaaiaadMhaaeqaaaaa@38E4@

σ

0

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aaS

baaSqaaiaaicdaaeqaaaaa@38A0@

σ

0

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aaS

baaSqaaiaaicdaaeqaaaaa@38A0@

Four HILL parameters for shell are automatically computed by

Radioss .

(18)

F

=

1

2

(

1

R

22

2

+

1

R

33

2

−

1

R

11

2

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOraiabg2

da9maalaaabaGaaGymaaqaaiaaikdaaaGaaiikamaalaaabaGaaGym

aaqaaiaadkfadaqhaaWcbaGaaGOmaiaaikdaaeaacaaIYaaaaaaaki

abgUcaRmaalaaabaGaaGymaaqaaiaadkfadaqhaaWcbaGaaG4maiaa

iodaaeaacaaIYaaaaaaakiabgkHiTmaalaaabaGaaGymaaqaaiaadk

fadaqhaaWcbaGaaGymaiaaigdaaeaacaaIYaaaaaaakiaacMcaaaa@489E@

(19)

G

=

1

2

(

1

R

33

2

+

1

R

11

2

−

1

R

22

2

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4raiabg2

da9maalaaabaGaaGymaaqaaiaaikdaaaGaaiikamaalaaabaGaaGym

aaqaaiaadkfadaqhaaWcbaGaaG4maiaaiodaaeaacaaIYaaaaaaaki

abgUcaRmaalaaabaGaaGymaaqaaiaadkfadaqhaaWcbaGaaGymaiaa

igdaaeaacaaIYaaaaaaakiabgkHiTmaalaaabaGaaGymaaqaaiaadk

fadaqhaaWcbaGaaGOmaiaaikdaaeaacaaIYaaaaaaakiaacMcaaaa@489F@

(20)

H

=

1

2

(

1

R

22

2

+

1

R

11

2

−

1

R

33

2

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamisaiabg2

da9maalaaabaGaaGymaaqaaiaaikdaaaGaaiikamaalaaabaGaaGym

aaqaaiaadkfadaqhaaWcbaGaaGOmaiaaikdaaeaacaaIYaaaaaaaki

abgUcaRmaalaaabaGaaGymaaqaaiaadkfadaqhaaWcbaGaaGymaiaa

igdaaeaacaaIYaaaaaaakiabgkHiTmaalaaabaGaaGymaaqaaiaadk

fadaqhaaWcbaGaaG4maiaaiodaaeaacaaIYaaaaaaakiaacMcaaaa@48A0@

(21)

N

=

3

2

R

12

2

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOtaiabg2

da9maalaaabaGaaG4maaqaaiaaikdacaWGsbWaa0baaSqaaiaaigda

caaIYaaabaGaaGOmaaaaaaaaaa@3C90@

In LAW74, yield stress ratio

R

i

j

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOuamaaBa

aaleaacaWGPbGaamOAaaqabaaaaa@38D7@

is used with yield stress

σ

11

,

σ

22

,

σ

33

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aaS

baaSqaaiaaigdacaaIXaaabeaakiaacYcacqaHdpWCdaWgaaWcbaGa

aGOmaiaaikdaaeqaaOGaaiilaiabeo8aZnaaBaaaleaacaaIZaGaaG

4maaqabaaaaa@41A0@

and

σ

12

,

σ

13

,

σ

23

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aaS

baaSqaaiaaigdacaaIYaaabeaakiaacYcacqaHdpWCdaWgaaWcbaGa

aGymaiaaiodaaeqaaOGaaiilaiabeo8aZnaaBaaaleaacaaIYaGaaG

4maaqabaaaaa@41A0@

input directly, and then six HILL parameters for

solid are automatically computed by

Radioss .

F

=

1

2

(

1

σ

22

2

+

1

σ

33

2

−

1

σ

11

2

)

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGgbGaey

ypa0ZaaSaaaeaacaaIXaaabaGaaGOmaaaadaqadaqaamaalaaabaGa

aGymaaqaaiabeo8aZnaaDaaaleaacaaIYaGaaGOmaaqaaiaaikdaaa

aaaOGaey4kaSYaaSaaaeaacaaIXaaabaGaeq4Wdm3aa0baaSqaaiaa

iodacaaIZaaabaGaaGOmaaaaaaGccqGHsisldaWcaaqaaiaaigdaae

aacqaHdpWCdaqhaaWcbaGaaGymaiaaigdaaeaacaaIYaaaaaaaaOGa

ayjkaiaawMcaaaaa@4BF9@

G

=

1

2

(

1

σ

22

2

+

1

σ

33

2

−

1

σ

11

2

)

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGhbGaey

ypa0ZaaSaaaeaacaaIXaaabaGaaGOmaaaadaqadaqaamaalaaabaGa

aGymaaqaaiabeo8aZnaaDaaaleaacaaIYaGaaGOmaaqaaiaaikdaaa

aaaOGaey4kaSYaaSaaaeaacaaIXaaabaGaeq4Wdm3aa0baaSqaaiaa

iodacaaIZaaabaGaaGOmaaaaaaGccqGHsisldaWcaaqaaiaaigdaae

aacqaHdpWCdaqhaaWcbaGaaGymaiaaigdaaeaacaaIYaaaaaaaaOGa

ayjkaiaawMcaaaaa@4BFA@

H

=

1

2

(

1

σ

22

2

+

1

σ

33

2

−

1

σ

11

2

)

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGibGaey

ypa0ZaaSaaaeaacaaIXaaabaGaaGOmaaaadaqadaqaamaalaaabaGa

aGymaaqaaiabeo8aZnaaDaaaleaacaaIYaGaaGOmaaqaaiaaikdaaa

aaaOGaey4kaSYaaSaaaeaacaaIXaaabaGaeq4Wdm3aa0baaSqaaiaa

iodacaaIZaaabaGaaGOmaaaaaaGccqGHsisldaWcaaqaaiaaigdaae

aacqaHdpWCdaqhaaWcbaGaaGymaiaaigdaaeaacaaIYaaaaaaaaOGa

ayjkaiaawMcaaaaa@4BFB@

L

=

1

2

σ

23

2

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGmbGaey

ypa0ZaaSaaaeaacaaIXaaabaGaaGOmaiabeo8aZnaaDaaaleaacaaI

YaGaaG4maaqaaiaaikdaaaaaaaaa@3DE1@

M

=

1

2

σ

31

2

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGnbGaey

ypa0ZaaSaaaeaacaaIXaaabaGaaGOmaiabeo8aZnaaDaaaleaacaaI

ZaGaaGymaaqaaiaaikdaaaaaaaaa@3DE1@

N

=

1

2

σ

12

2

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGobGaey

ypa0ZaaSaaaeaacaaIXaaabaGaaGOmaiabeo8aZnaaDaaaleaacaaI

XaGaaGOmaaqaaiaaikdaaaaaaaaa@3DE1@

For shell element, take

M

=

N

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGnbGaey

ypa0JaamOtaaaa@3909@

L

=

N

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGnbGaey

ypa0JaamOtaaaa@3909@