/MAT/LAW23 (PLAS_DAMA)

Block Format Keyword This law models an isotropic elastic plastic material and combines Johnson-Cook material model with a generalized damage model. The law is applicable only for solid elements.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW23/mat_ID/unit_ID or /MAT/PLAS_DAMA/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | |||||||||

| a | b | n | |||||||

| c | ICC | ||||||||

| Et | |||||||||

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material

identifier (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier (Integer, maximum 10 digits) |

|

| mat_title | Material

title (Character, maximum 100 characters) |

|

| Initial

density (Real) |

||

| E | Young's

modulus (Real) |

|

| Poisson's

ratio (Real) |

||

| a | Plasticity yield stress -

should be strictly positive. (Real) |

|

| b | Plasticity hardening

parameter. (Real) |

|

| n | Plasticity hardening

exponent. 3 (Real) |

|

| Failure plastic

strain. Default = 1030 (Real) |

||

| Plasticity maximum

stress. Default = 1030 (Real) |

||

| c | Strain rate coefficient.

Default = 0.00 (Real) |

|

| Reference strain

rate. If , no strain rate effect. (Real) |

||

| ICC | Strain rate computation

flag. 5

(Integer) |

|

| Damage model starts at

. Default = 0.15 (Real) |

||

| Et | Softening damage slope (

). Default = 0.00 (Real) |

Example (Aluminum)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

g mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW23/1/1

Alu

# RHO_I

.0027

# E nu

70000 .3

# a b n Eps_max sig_max0

100 0 1 .2 100

# c EPS_0 ICC

0 0 0

# EPS_dam E_t

.1 -2000

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- The damage law is applied to the stress tensor and damage occurs in tension, compression and shear.

- The input is the same as material law (/MAT/LAW22 (DAMA)).

- The plasticity hardening exponent n must be less than one.

- When reaches , in one integration point, then the solid element is deleted.

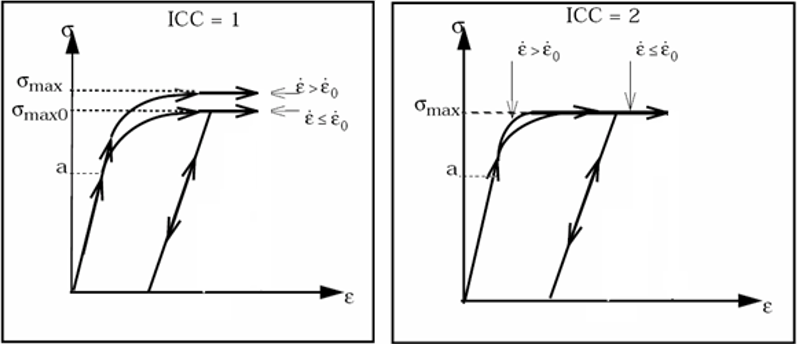

- ICC is a flag of the strain

rate effect on material maximum stress

.

Figure 1.