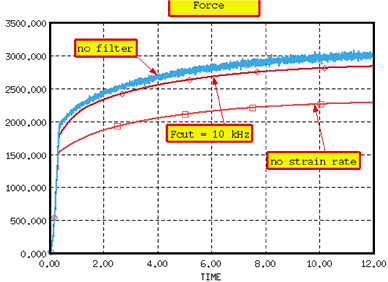

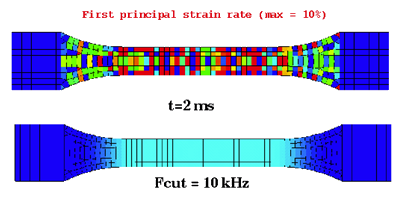

The strain rates exhibit very high frequency vibrations which are not physical. The

strain rate filtering option will enable to damp those oscillations and; therefore obtain

more physical strain rate values.

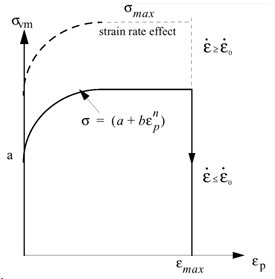

If there is no strain rate filtering, the equivalent strain rate is the maximum value

of the strain rate components:(7)

For thin-walled structures, the equivalent strain is computed by the following

approach. If ε is the main component of strain tensor, the kinematic assumptions of

thin-walled structures allows to decompose the in-plane strain into membrane and

flexural deformations:(8)

Then, the expression of internal energy can by written as:

(9)

Therefore:(10)

The expression can be simplified to:

(11)

(12)

The expression of the strain rate is derived from

Equation 8:

(13)

Admitting the assumption that the strain rate is proportional to the strain,

i.e.:(14)

(15)

Therefore:(16)

Referring to

Equation 12, it can be seen that

an equivalent strain rate can be defined using a similar expression to the

equivalent strain:

(17)

(18)

For solid elements, the strain rate is computed using the maximum element

stretch:(19)

The strain rate at integration point,

in

/ANIM/TENS/EPSDOT/i

is calculated by:

(20)

Where,

- Membrane strain rate /ANIM/TENS/EPSDOT/MEMB

- Bending strain rate /ANIM/TENS/EPSDOT/BEND.

The strain rate in upper and lower layers is computed by:(21)

/ANIM/TENS/EPSDOT/UPPER(22)

/ANIM/TENS/EPSDOT/LOWER

The strain rate is filtered by using:(23)

Where,

- Time interval

- Fcut

- Cutting frequency

- Filtered strain rate