This law models an elasto-plastic material with:

- Isotropic and kinematic hardening

- Tensile rupture criteria

The damage is neglected in the model. The work hardening model is similar to the

Johnson-Cook model (LAW2) without temperature effect where the only difference is in the

strain rate dependent formulation. The equation that describes the stress during plastic

deformation is:

(1)

Where,

-

- Flow stress (Elastic + Plastic Components)

-

- Plastic strain (True strain)

-

- Yield stress

-

- Hardening modulus

-

- Hardening exponent

-

- Strain rate coefficient

-

- Strain rate

-

- Strain rate exponent

The implanted model in Radioss allows the cyclic hardening with

a combined isotropic-kinematic approach.

The coefficient Chard

varying between zero and unity is introduced to regulate the weight between isotropic and

kinematic hardening models.

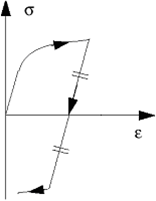

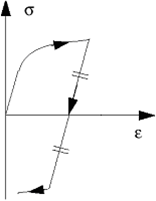

In isotropic hardening model, the yield surface inflates without moving in the space of

principle stresses. The evolution of the equivalent stress defines the size of the yield

surface, as a function of the equivalent plastic strain. The model can be represented in one

dimensional case as shown in

Table 1. When the loading direction is changed, the material is unloaded and the

strain reduces. A new hardening starts when the absolute value of the stress reaches the

last maximum value (

Table 1 (a)).

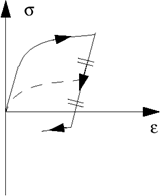

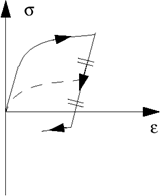

Table 1. Isotropic and Kinematic Hardening Models for Deformation Decrease

| (a) Isotropic

hardening |

(b)

Prager-Ziegler kinematic hardening |

|

|

This law is available for solids and shells. Refer to the Radioss Reference Guide for more information about

element/material compatibilities.