/MAT/LAW72 (HILL_MMC)

Block Format Keyword This law describes the anisotropic Hill material with a modified Mohr fracture criteria. This law is available for shell and solid.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW72/mat_ID/unit_ID or /MAT/HILL_MMC/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | v | ||||||||

| n | F | G | |||||||

| H | N | L | M | ||||||

| C1 | C2 | C3 | m | Dc | |||||

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial density. (Real) |

||

| E | Initial Young's modulus. (Real) |

|

| v | Poisson's ratio. (Real) |

|

| Initial yield stress. Default = 1030 (Real) |

||

| Initial plastic strain. (Real) |

||

| n | Exponent for the isotropic function for the swift hardening:

It is also used as an exponent in the MMC failure equations. 2 (Real) |

|

| F, G, H, L, M, N | Six

HILL Materials anisotropic

parameters. (float) |

|

| C1 | First parameter for MMC fracture model. (Real) |

|

| C2 | Second parameter for MMC fracture model. (Real) |

|

| C3 | Third parameter for MMC fracture model. (Real) |

|

| m | Exponent for the softening function. 3 (Real) |

|

| Dc | Critical damage.

(Real) |

Example (Metal)

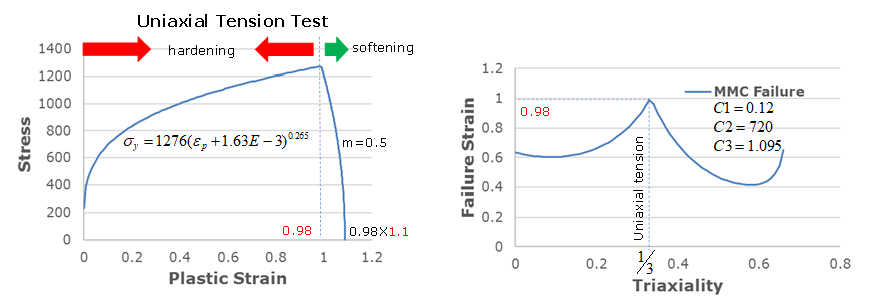

Figure 1.

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

g mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW72/1/1

Metal

# RHO_I

0.0028

# E nu

200E+3 0.3

# Sig0 Eps0 n F G

1276 1.63E-3 0.265 0.5 0.5

# H N L M

0.5 1.5 0 0

# C1 C2 C3 m Dc

0.12 720 1.095 0.5 1.1

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

Comments

- 3D

equivalent Hill stress:

(1) For shell element, take:(2) - MMC

fracture criteria:

(3) - Anisotropic 3D model

(4) While,

is Lode angle

with Lode angle parameter

is the third invariant of the deviatoric stress.

is stress triaxiality with

- 2D Anisotropic Model

(5) with,(6) (7) (8)

- Anisotropic 3D model

- Fracture and damage

with MMC fracture criteria:

- When D = 1: fracture initiate

- By 1 < D <

Dc: the yield stress is multiplied by

softening function

to reduce the deformation resistance.

with

- If D ≥ Dc, the element is deleted.

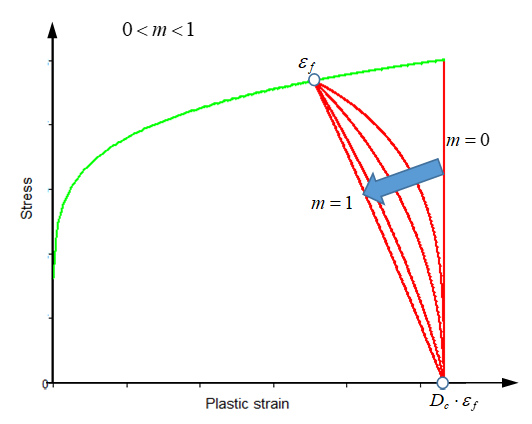

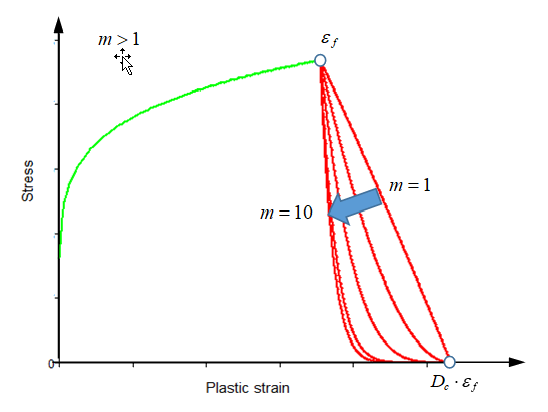

- The exponent m is used to describe the softening behavior. It is

recommended to use m > 0.

If 0 < m < 1, then the softening curve is convex.

If m > 1, then the softening curve is concave. The softening is between and . Once the plastic strain is reached (in this case ), then the element is deleted.

Figure 2.

Figure 3.

- It is possible to

display user variables in animation files (with Engine /ANIM/Eltyp/Restype) and in Time history file (with Starter /TH/SHEL and /TH/BRIC):

- USER1: Plastic strain

- USER2: Damage value