/MAT/LAW57 (BARLAT3)

Block Format Keyword This law describes plasticity hardening by a user-defined function and can be used only with shell elements.

This is an elasto-plastic orthotropic law for modeling anisotropic materials in forming processes especially aluminum alloys. This material law must be used with property set type /PROP/TYPE9 (SH_ORTH) or /PROP/TYPE10 (SH_COMP).

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW57/mat_ID/unit_ID or /MAT/BARLAT3/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | |||||||||

| fct_IDE | Einf | CE | |||||||

| r00 | r45 | r90 | Chard | m | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fct_IDi | Fscalei | ||||||||

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier (Integer, maximum 10 digits) |

|

| mat_title | Material title (Character, maximum 100 characters) |

|

| Initial density (Real) |

||

| E | Young's modulus (Real) |

|

| Poisson's ratio (Real) |

||

| fct_IDE | Function identifier for the scale factor

of Young's modulus, when Young's modulus is function of the plastic strain. 11 Default = 0: in this case the evolution of Young's modulus depends on Einf and CE. (Integer) |

|

| Einf | Saturated Young's modulus for infinitive

plastic strain. (Real) |

|

| CE | Parameter for Young's modulus

evolution. (Real) |

|

| r00 | Lankford parameter 0 degree. Default = 1.0 (Real) |

|

| r45 | Lankford parameter 45 degrees. Default = 1.0 (Real) |

|

| r90 | Lankford parameter 90 degrees. Default = 1.0 (Real) |

|

| Chard | Hardening coefficient.

(Real) |

|

| m | Barlat parameter.

(Real) |

|

| Failure plastic strain. Default = 1.0 x 1030 (Real) |

||

| Tensile failure strain at which stress

starts to reduce. Default = 1.0 x 1030 (Real) |

||

| Maximum tensile failure damage strain at

which the stress in element is set to zero. Default = 2.0 x 1030 (Real) |

||

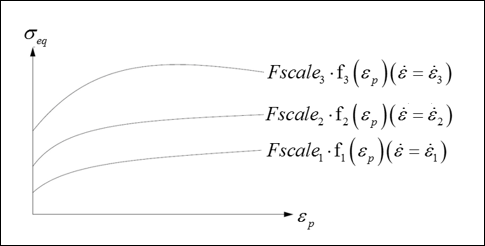

| fct_IDi | Plasticity curves

ith function identifier. (Integer) |

|

| Fscalei | Scale factor for

ith function. Default set to 1.0 (Real) |

|

| Strain rate for

ith function. (Real) |

Example (Steel)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

g mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW57/1/1

Steel

# RHO_I

.008

# E NU

206000 .300000012

# fct_IDE E_INF CE

0 0 0

# r00 r45 r90 C_hard m

1.79 1.51 2.27 0 0

# EPSP_max EPS_T EPS_M

0 0 0

# fct_ID Fscale_i EPS_i

5 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 3. FUNCTIONS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/5

function_5

# X Y

0 157

.1 320

.5 480

1.2 600

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- The anisotopic yield criteria

F for plane stress is defined by:

(1) Where,

is the yield stress

and

- Angles for Lankford parameters are defined with respect to orthotropic direction 1.

The material constants a, c, h, and

p are obtained from the three Lankford parameters:

(2) Material constant p is calculated by solving:(3) - If the last point of the first (static) function equals 0 in stress, the default value of is set to the corresponding value of .

- If (plastic strain) reaches , in one integration point, the corresponding shell element is deleted.

- If the largest principal strain

, the stress is reduced using the following

relation:

(4) - If , the stress is reduced to 0 (but the element is not deleted).

- The maximum number of curves is 10.

- If , the yield is interpolated between fn and fn-1.

- If , function f1 is used.

- Above

, yield is extrapolated.

Figure 1. - The evolution of

Young's modulus:

- If fct_IDE > 0, the curve defines a scale factor for Young's modulus evolution with equivalent

plastic strain, which means the Young's modulus is scaled by the function

:

(5) The initial value of the scale factor should be equal to 1 and it decreases.

- If fct_IDE = 0, the Young's modulus is calculated as:

(6) Where, E and Einf are respectively the initial and asymptotic value of Young's modulus, and is the accumulated equivalent plastic strain.

Note: If fct_IDE = 0 and CE = 0, Young's modulus, E is kept constant.

- If fct_IDE > 0, the curve defines a scale factor for Young's modulus evolution with equivalent

plastic strain, which means the Young's modulus is scaled by the function

: