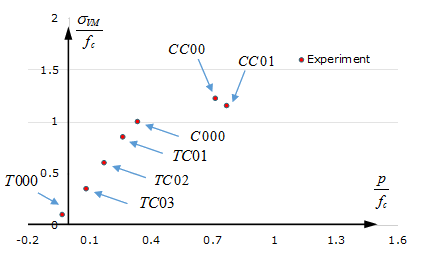

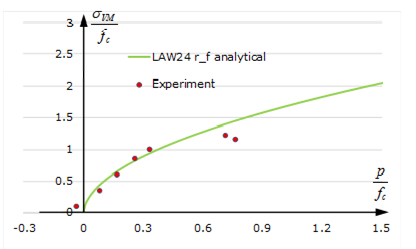

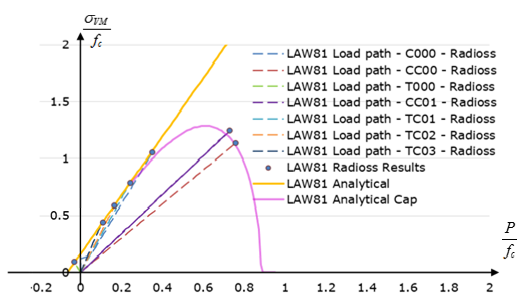

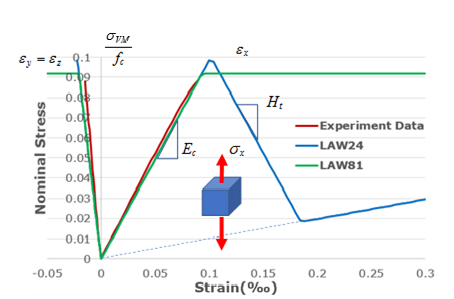

| T000 Uniaxial tension

|

; ; |

1/3 |

0.1 |

| C000 Uniaxial compression

|

; ; |

-1/3 |

|

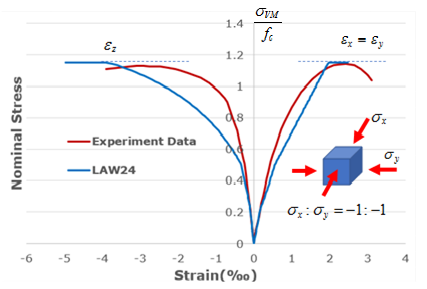

| CC00 Biaxial compression

|

; ; |

-2/3 |

1.15 |

| CC01 Compression/Compression

|

; ; |

-0.5849 |

1.22 |

| TC01 Compression/Tension

|

; ; |

-0.3077 |

0.8 |

| TC02 Compression/Tension

|

; ; |

-0.2838 |

0.6 |

| TC03 Compression/Tension

|

; ; |

-0.2377 |

0.35 |