/MAT/LAW81

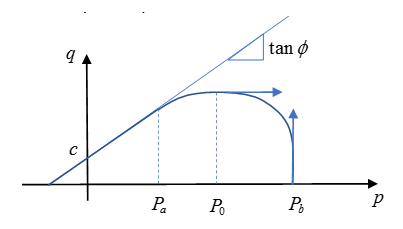

Block Format Keyword This law is based on Drücker-Prager yield criteria with cap. It has a strain-hardening cap model based on the principles of Foster. Plasticity has an isotropic hardening.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW81/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| K0 | G0 | c0 | Pb0 | ||||||

| α | Eps_max | ||||||||

| fct_IDK | fct_IDG | fct_IDC | fct_IDPb | Isoft | |||||

| Kw | n0 | S0 | U0 | ||||||

| Tol | |||||||||

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material

identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material

title. (Character, maximum 100 characters) |

|

| Initial

density. (Real) |

||

| K0 | Initial bulk

modulus. (Real) |

|

| G0 | Initial shear

modulus. (Real) |

|

| c0 | Initial material

cohesion. (Real) |

|

| Pb0 | Initial cap limit

pressure. (Real) |

|

| Friction

angle. (Real) |

||

| Plastic flow

angle. (Real) |

||

| α | Ratio of:

Default = 0.5 (Real) |

|

| Eps_max | Maximum dilatancy

(negative number limiting

). Default = -1020 (Real) |

|

| Initial value of the

plastic volumetric strain. 3 (Real) |

||

| fct_IDK | (Optional) Function

identifier for the bulk modulus scale factor vs the plastic

volumetric strain. 4 (Integer) |

|

| fct_IDG | (Optional) Function

identifier for the shear modulus scale factor vs the plastic

volumetric strain. (Integer) |

|

| fct_IDC | (Optional) Function

identifier for the material cohesion scale factor vs the equivalent

plastic strain. (Integer) |

|

| fct_IDPb | (Optional) Function

identifier for the cap limit pressure scale factor vs the plastic

volumetric strain. (Integer) |

|

| Isoft | Cap softening flag.

(Integer) |

|

| Kw | Pore bulk modulus

(water). (Real) |

|

| n0 | Initial

porosity. (Real) |

|

| S0 | Initial

saturation. (Real) |

|

| U0 | Initial pore

pressure. (Real) |

|

| Tol | Tolerance for cap shift

viscosity. Default = 1.0E-4 (Real) |

|

| Viscosity

factor. Default = 0.5 (Real) |

Example

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

kg m s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW81/1/1

LAW81

# RHO_I

1700

# K0 G0 c0 PB0

2.83E9 1.31E9 1 1

# BETA PSI

15 10

# ALPHA EPS_p_max EPS_0

.5 .02 .002

# Fct_IDK Fct_IDG Fct_IDc Fct_IDPb I_soft

0 0 3 4 1

# Kw n0 S0 U0

2.5E10 0.1 0.99 0.0

# Tol alpha_v

0.0001 0.5

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 3. FUNCTIONS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/3

Yield Hardening

# X Y

0 2000

.1 2002000

1 2002000

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/4

Cap Hardening

# X Y

-1 1000

0 1000

.001 30000

.0022 70000

.0024 80000

.004 100000

.0056 200000

.0078 800000

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- The yield surface is defined

as:

(1) Where,

if

if

Where,- p

- Pressure

- q

- von Mises stress

- c

- Material cohesion

- P0

- Pressure, where

- pb

- Cap limit pressure

Figure 1.In this material, yield surface and failure surface are the same.

- Plastic flow is governed by the

non-associated flow potential G, as:

if

if

if , the flow becomes associated on the cap.

- If cap softening is allowed, can decrease, therefore it is recommended to define the following curves on a relevant range. For example, if , negative values.

- The initial values for bulk

modulus, shear modulus, material cohesion, and cap limit pressure can be scaled

by defining a function as the scale factor curve for each respective value. If

the function is not defined, then the value is considered constant. For

example:

If fct_IDK = 0 then,

If fct_IDK ≠ 0 then, , with the function defined in fct_IDK

- The initial bulk modulus and shear

modulus can be calculated as:

;

With,- Poisson’s ratio

- Young’s modulus of concrete

- The porosity is defined so that

it represents the volume fraction of voids, with respect to the total material

volume.

(2) In the elastic case, the void volume does not change. However, in the plastic case, the porosity change is defined by:(3) - Effect of pores filled with

water: The initial state of the pores is defined by the initial porosity, initial saturation, and initial pore pressure n0, U0 and S0 which can be calculated as:

(4) If the then the entered value for S0 is not used and instead S0 is recalculated.

- The following user variables are

available for post-treatment:

USR1 is the equivalent plastic strain EPSPD

USR2 is the plastic volumetric strain EPSPV

USR3 is the cohesion c

USR4 is the cap limit pressure Pb

USR5 pore pressure U

USR6 porosity n

USR7 saturation S

USR8 cap shift