RD-E: 4601 Lagrange Formulation

This example shows how to simulate the cylinder expansion test and compare the simulation result to experimental data.

Detonation is initiated at the bottom of the explosive. Radial expansion of the cylinder is measured and compared to experimental data.

Options and Keywords Used

- Lagrange formulation

- Jones-Wilkins-Lee EOS (/MAT/LAW5 (JWL))

- Hydrodynamic Johnson-Cook Material (/MAT/LAW4 (HYD_JCOOK))

- Gruneisen equation of state (/EOS/GRUNEISEN)

- Brick elements

- Axisymmetrical analysis (/ANALY)

- Solid property (/PROP/TYPE14 (SOLID))

- Boundary condition (/BCS)

- Detonation plan (/DFS/DETPLAN)

- Time history on node (/TH/NODE)

Due to the symmetries of the model, a quarter of the cylinder is modeled. Boundary conditions are set on the yOz plan at x = 0 (Tx = 0) and on the xOz plan at y = 0 (Ty = 0) to simulate the symmetry.

A planar detonation wave is defined at the bottom of the cylinder.

A scale factor of 0.5 (on time step for all elements) is used for this type of application.

- Isolid is set to 14 for copper solid properties.

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/PROP/SOLID/2

TNT

# Isolid Ismstr Icpre Itetra10 Inpts Itetra4 Iframe dn

0 0 0 0 0 0 0 0

# q_a q_b h LAMBDA_V MU_V

0 0 0 0 0

# dt_min istrain IHKT

0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/PROP/SOLID/1

Copper

# Isolid Ismstr Icpre Itetra10 Inpts Itetra4 Iframe dn

0 0 0 0 0 0 0 0

# q_a q_b h LAMBDA_V MU_V

0 0 0 0 0

# dt_min istrain IHKT

0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Input Files

- Cylinder Test

- <install_directory>/hwsolvers/demos/radioss/example/46_TNT_Cylinder_Expansion_Test/Lagrange/*

Model Description

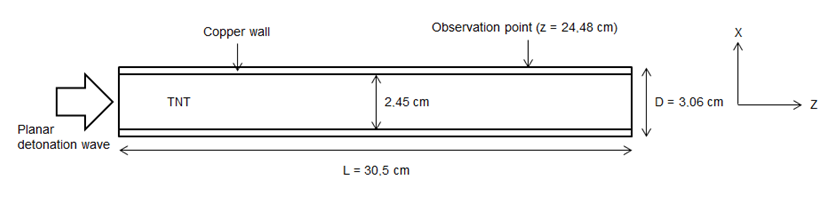

A OFHC copper cylinder (1.53cm diameter, 0.26cm thickness, 30.5cm height) is filled with an explosive (TNT). Detonation is initiated at the bottom of the explosive. Radial expansion is measured at a length of 8*D cm.

Figure 1. Problem Description for Cylinder Test

Units: cm, s, g, Mbar

- Material Properties

- Initial density

- 1.63

- A

- 3.7121

- B

- 0.0323

- R1

- 4.15

- R2

- 0.95

- 0.3

- Detonation velocity D

- 0.693

- Chapman Jouguet pressure PCJ

- 0.21

- Detonation energy E0

- 0.07

Radioss Card (TNT)

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/JWL/2

TNT

# RHO_I

1.63

# A B R1 R2 OMEGA

3.7121 .0323 4.15 .95 .3

# D P_CJ E0 Eadd I_BFRAC Q_OPT

.693 .21 .07 0 0 0

# Tstart Tstop a m n

0 0 0 0 0

# P0 Psh a_unit

0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|- Material Properties

- Initial density

- 8.96

- E-Module

- 1.24

- Poisson's ratio

- 0.35

- A

- 0.9e-3

- B

- 0.292e-2

- N

- 0.31

- 0.0066

- C

- 0.025

- 1e-5

- M

- 1.09

- 3.461e-3

- Tmelt

- 1656

- Material Properties

- C

- 0.394

- S1

- 1.489

- 1.97

- a

- 0.47

- E0

- 8.96

Radioss Card (Copper)

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/HYD_JCOOK/1

Copper

# RHO_I

8.96

# E0 nu

1.24 .35

# A B n epsmax sigmax

.9E-03 .292E-02 .31 0 0.0066

# Pmin

-1.E30

# C EPS_DOT_0 M Tmelt Tmax

.25E-01 .1E-05 1.09 1656.0 1e30

# RHOCP Tr

3.461E-5 0

/EOS/GRUNEISEN/1

Copper

# C S1 S2 S3

.394 1.489 0 0

# GAMMA0 ALPHA E0 RHO_0

1.97 .47 0 8.96

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Model Method

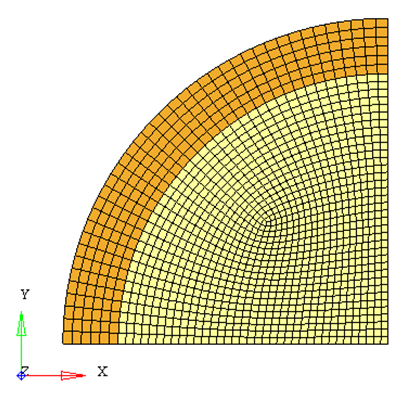

A 3D mesh is made of brick elements. The element size is approximately of 0.035 cm x 0.035 cm x 0.035 cm.

Figure 2. Model Mesh

Results

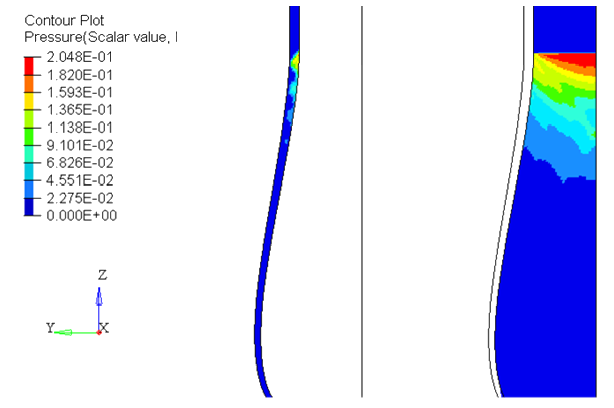

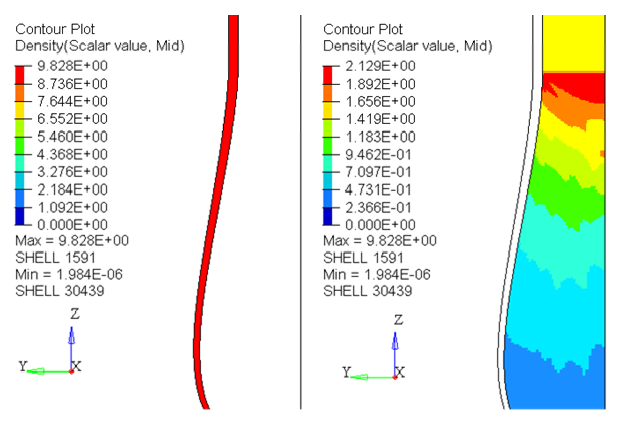

Curves and Animations

Figure 3. Pressure Distributed in Copper and TNT at time = 11s

Figure 4. Density Distributed in Copper and TNT at time = 11 s

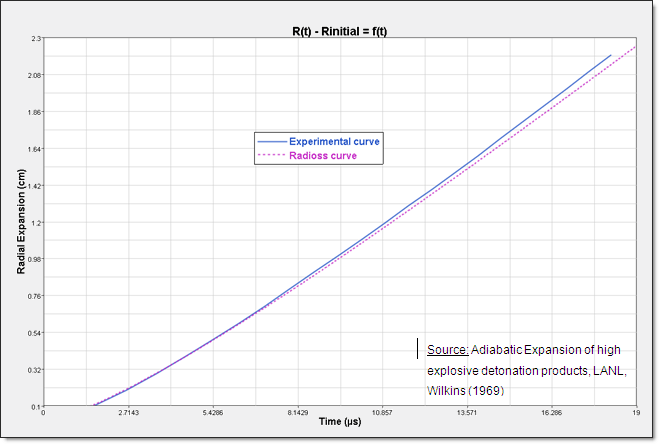

Figure 5. Comparison Between Experimental Results and Simulation Results

Conclusion

Good correlation between experimental and simulation results. A thinner meshing could improve the correlation between simulation and experimental curves.

Elapsed time for simulation: t = 11 441 s, 8514 cycles, (4 cpu intel core i7 Q 840 @ 1.87 GHz).

As the model is Lagrangian, the mesh becomes very distorted at the end of the simulation to obtain a proper mesh, it is possible to use the Euler method.