Centrifugal Pump Elements

Radial Flow Pump General Description & Quick Guide

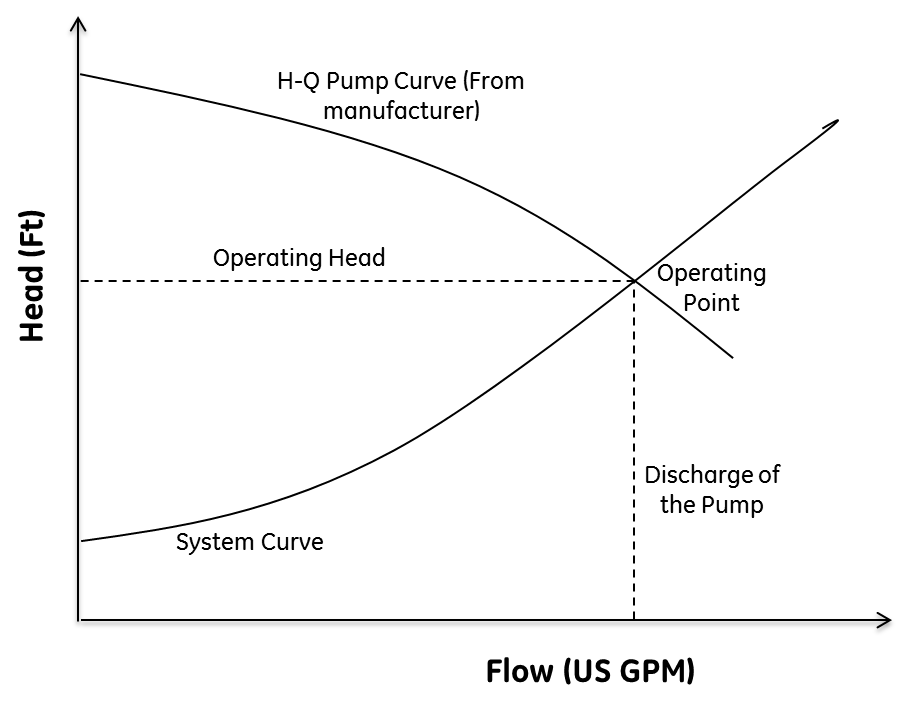

The Radial Flow pump element routine simulates only for Incompressible Liquids. Radial flow pump requires Pump Characteristic curve or Pump Parameters to be entered. In Steady State, the pressure loss for a system is calculated for a range of flow rates. The point where the derived pressure loss flow rate curve intersects the pump curve defines the operating point of the system. If the curves do not intersect, or intersect far from the best efficiency point, then the pump selected is unsuitable for the system

Figure: Pump Operating Point

There are different Subtypes of Centrifugal Pump available in FlowSimulator. They are

- Radial Flow: User Specify Pump Characteristic Curves for Design Point. For Off Design Characteristics the pump homologous laws are used to correct head which is generated for a given pump speed and flow rate

- Data Based Pumps: Similar to Subtype of Radial flow, But the Pump Characteristic Curves are provided as Surface Data obtained from a manufacturer’s performance data as 'Head v Flow Rate and Speed'

Radial Flow Pump Element Inputs

Table of the inputs for the Centrifugal Pump Element.

| Element Specific Radial Flow Pump Element Input Variables | ||

|---|---|---|

| Index | UI Name (. flo label) | Description |

| 1 | Subtype |

Type of Pump

|

| 1 | Rated Flow | The design (or rated) point for the pump, i.e. the point at which the pump is designed to operate |

| 2 | Rated Head | The design (or rated) point for the pump, i.e. the point at which the pump is designed to operate. You should note that for a given head curve, the pump pressure will be dependent on the density of the liquid in your network |

| 3 | Rated Speed | The design (or rated) point for the pump, i.e. the point at which the pump is designed to operate. |

| 4 | Rated Power | The design (or rated) point for the pump, i.e. the point at which the pump is designed to operate. |

| 5 | Rated Efficiency | The design point (or rated) point for the pump, i.e. the point at which the pump is designed to operate. |

| 6 | Friction Torque | User Specified value of friction torque |

| 7 | Operating Speed | The speed at which the pump runs in Steady State |

| 8 | Portion of Ustrm Chamb. Dyn. Head Lost (DQ_IN) | Inlet dynamic head loss. Refer General solver theory sections for more details about this input |

| 9 | Element Inlet Orientation: Tangential Angle (THETA) |

Angle between the element centerline at the entrance of the element and the reference direction. If the element is rotating or directly connected to one or more rotating elements, the reference direction is defined as parallel to the engine centerline and the angle is the projected angle in the tangential direction. Otherwise, the reference direction is arbitrary but assumed to be the same as the reference direction for all other elements attached to the upstream chamber.

THETA for an element downstream of a plenum chamber has no impact on the solution except to set the default value of THETA_EX. (See also THETA_EX) |

| 10 | Element Inlet Orientation: Radial Angle (PHI) |

Angle between the element centerline at the entrance of the element and the THETA direction. (spherical coordinate system)

PHI for an element downstream of a plenum chamber has no impact on the solution except to set the default value of PHI_EX. (See also PHI_EX) |

| 11 | Element Exit Orientation: Tangential Angle (THETA_EX) |

Angle between the orifice exit centerline and the reference direction. THETA_EX is an optional variable to be used if the orientation of the element exit differs from that of the element inlet.

The default value (THETA_EX = -999) will result in the assumption that THETA_EX = THETA.

Other values will be interpreted in the manner presented in the description of THETA. |

| 12 | Element Exit Orientation: Radial Angle (PHI_EX) |

Angle between the orifice exit centerline and the THETA_EX direction.

PHI_EX is an optional variable to be used if the orientation of the element exit differs from that of the element inlet.

The default (PHI_EX = -999) will result in the assumption that PHI_EX = PHI.

Other values will be interpreted in the manner presented in the description of PHI. |

| 13 | Exit Area (EXIT_AREA) | Pump Exit area |

| 19 | Head Curve | Vol.Flow Vs Head Curve (Pump Curve) (Used for Radial Flow Pump) |

| 20 | Torque Curve | Vol.Flow Vs Torque Curve (Pump Curve) (Used for Radial Flow Pump) |

| 23 |

FLOWRATE / (DELTAP/HEAD) / SPEED |

Surface data of Head/Delta.P v Flow Rate and Speed (Used for Data Based Pumps) |

| 24 |

FLOWRATE/DELTA-P / EFFICIENCY /SPEED |

Surface data of ‘Flowrate/ Delta -P vs Efficiency and Speed (Used for Data Based Pumps) |

Radial Flow Pumps Theory Manual

Mass Flow Rate Calculation

For Radial Flow Pumps:

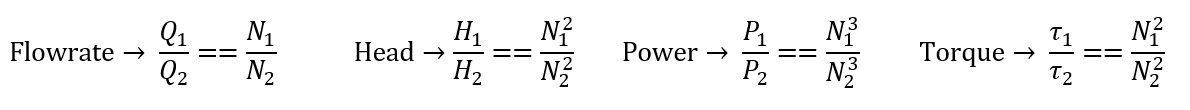

If the pump is rotating at its rated speed, then delta P is used to get the GPM and then the torque from the user supplied tables. If the pump is operating at off design conditions, then the Head & Toque curve are scaled. The pump homologous laws are used to correct head which is generated for a given pump speed and flow rate. The same logic is applied for a transient simulation where pump speed may vary. The laws state the following relationships for flow rate, head, power and torque with varying speed:

Where N = Speed, Q = Flow rate, H = Head, P = Power, τ = Torque

For Data Based Pumps:

The delta P is used to get the GPM & Efficiency directly from User Supplied curves.

Note: FlowSimulator uses linear interpolation to obtain values from the curves, & it doesn’t do any extrapolation if the values are outside the prescribed input limits. If X-Value is less than its first value entry in the table, the first Y-Value entry is used. If X-Value is greater than its last value entry in the table, the last Y-Value entry is used A detailed error & warning messages are written out in Convhist_fi.out file.

Other Outputs:

IMP_TORQUE = RATED_TORQUE + TORQUE

SHAFT_TORQUE = FRIC_TORQUE + IMP_TORQUE

SHAFT_POWER(HP) = SHAFT_TORQUE * OMEGA / 550.0D0

HYD_POWER(HP) = 231.0 / 60.0 / 12.0 / 550.0 * GPM * DELTA_P_RISE

HYD_TORQUE = 231.0 / / 12.0* GPM * DELTA_P_RISE / SPEED

EFFICIENCY = HYD_TORQUE / SHAFT_TORQUE

FLOW_WORK = RATED_POWER *(745.69987/0.293071) * EFFICIENCY/1000

HEAT_DUTY = RATED_POWER *(745.69987/0.293071) * (1.0D0-EFFICIENCY)/1000

Additional Momentum Loss

For Additional Momentum loss, Portion of Upstream Dynamic Head loss refer Solver General theory section.

Radial Flow Element Outputs

The following listing provides details about conventional orifice output variables.

| Name | Description | Units |

|---|---|---|

| Rated Flow |

The design (or rated) point for the pump, i.e. the point at which the pump is designed to operate (Usually an echo of the user input unless modified inside Flow Simulator.) |

GPM, m3/sec |

| Rated Head | The design (or rated) point for the pump, i.e. the point at which the pump is designed to operate. (Usually an echo of the user input unless modified inside Flow Simulator.) | Ft, m |

| Rated Speed |

The design (or rated) point for the pump, i.e. the point at which the pump is designed to operate. (Usually an echo of the user input unless modified inside Flow Simulator.) |

Rpm |

| Rated Power |

The design (or rated) point for the pump, i.e. the point at which the pump is designed to operate. (Usually an echo of the user input unless modified inside Flow Simulator.) |

Hp, W |

| VOL.FLOW | Volumetric Flow | GPM, m3/sec |

| HEAD | Head (Delta.P/density) | Ft, m |

| PRESSURE_RISE | Pressure Rise across Pump | psi, mPa |

| OPERATING_SPEED | Pump Operating Speed | RPM |

| FRICTION_TORQUE | Frictional Torque | Ft-lbm, N-m |

| IMPELLER_TORQUE | Impeller Torque (Refer Theory Part) | Ft-lbm, N-m |

| SHAFT_TORQUE | Shaft Torque (Refer Theory Part) | Ft-lbm, N-m |

| HYDRODYNAMIC_TORQUE | Hydrodynamic Torque (Refer Theory Part) | Ft-lbm, N-m |

| EFFICIENCY | Pump Efficiency | None |

| HYDRODYNAMIC_POWER | Hydrodynamic Power | Hp, W |

| SHAFT_POWER | Shaft Power | Hp, W |

| HEAT_DUTY | Hear Duty (Refer Theory Part) | Hp, W |

| FLOW_WORK | Flow Work (Refer Theory Part) | Hp, W |

| SPECIFIC_SPEED | Specific Speed of Pump (SPEED * SQRT(GPM)/(HEAD**(3.0/4.0))) | RPM * GPM^.5 / ft^.75 |

| NPSH_AVAILABLE | Net Positive Suction Head Available (Inlet Pressure / Density) | Ft, m |

| DQ_IN |

Portion of Ustrm Chamb. Dyn. Head Lost (Usually an echo of the user input unless modified inside Flow Simulator.) |

Flag |

| ELEMENT_THETA |

Tangential Angle (Usually an echo of the user input but converted to radians.) |

radians |

| ELEMENT_PHI |

Radial Angle (Usually an echo of the user input but converted to radians.) |

radians |

| PTS | Driving pressure relative to the rotational reference frame (i.e. rotor) at the restriction inlet. | psi, mPa |

| PTEX | Total pressure relative to the rotational reference frame (i.e. rotor) at the restriction exit including supersonic effects. | psi, mPa |

| PSEX |

Static pressure relative to the rotational reference frame (i.e. rotor) at the restriction exit. Limited by critical pressure ratio for supersonic flows. |

psi, mPa |

| PSEB | Effective sink (static) pressure downstream of the restriction. | psi, mPa |

| TTS | Total temperature of fluid relative to the rotational reference frame (i.e. rotor) at the restriction inlet. | deg F, K |