/FAIL/SNCONNECT

Block Format Keyword Describes the failure model for CONNECTION material with plastic displacement criteria. This model allows a different failure behavior in normal and shear directions.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /FAIL/SNCONNECT/mat_ID/unit_ID | |||||||||

| Ifail_so | ISYM | ||||||||

| fct_ID0N | fct_ID0S | fct_IDFN | fct_IDFS | XSCALE_0 | XSCALE_F | AREAscale | |||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fail_ID |

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier (Integer, maximum 10 digits) |

|

| Parameter for the beginning of

damage, due to moment loads. 2 (Real) |

||

| Exponent for the beginning of damage,

due to combined shear and normal loads. 2 (Real) |

||

| Parameter for the final damage failure,

due to moment loads. 2 (Real) |

||

| Exponent for the final damage failure,

due to combined shear and normal loads. 2 (Real) |

||

| Ifail_so | Solid failure flag.

(Integer) |

|

| ISYM | Rupture deactivation flag for compression.

(Integer) |

|

| fct_ID0N | Function identifier defining a scale

factor for displacement rate dependency in normal direction in initial yield

function. Default = 0 (Integer) |

|

| fct_ID0S | Function identifier defining a scale

factor for displacement rate dependency in tangential direction in initial yield

function. Default = 0 (Integer) |

|

| fct_IDFN | Function identifier defining a scale

factor for displacement rate dependency in normal direction in rupture yield

function. Default = 0 (Integer) |

|

| fct_IDFS | Function identifier defining a scale

factor for displacement rate dependency in tangential direction in rupture yield

function. Default = 0 (Integer) |

|

| XSCALE_0 | Scale factor for the abscissa

displacement rate for initial function. Default = 1.0 (Real) |

|

| XSCALE_F | Scale factor for the abscissa

displacement rate for rupture function. Default = 1.0 (Real) |

|

| AREAscale | Failure scale factor for area

increase. 5 Default = 0.0, this option is not used (Real) |

|

| fail_ID | Failure

criteria identifier. 3 (Integer, maximum 10 digits) |

Example (Connect)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

kg mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW83/1/1

CONNECT MATERIAL

# RHO_I

7.8E-6

# E Imass

20 0

# Fct_ID1 Y_scale1 X_scale1 ALPHA BETA

200 1 1 0 2

# RN RS Fsmooth Fcut

.2 .4 0 0

# Fct_IDN Fct_IDS XSCALE

0 0 0

/FAIL/SNCONNECT/1/1

# ALPHA_0 BETA_0 ALPHA_F BETA_F Ifail_so ISYM

0 2 0 2 1 1

# Fct_0N Fct_0S Fct_FN Fct_FS XSCALE_0 XSCALE_F AREAscale

2001 2002 2003 2004 1 1 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 3. FUNCTIONS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/200

MAT83 curve

# X Y

0 1

1 1

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/2001

Fct_0N

# X Y

0 .5

1 .5

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/2002

Fct_0S

# X Y

0 .5

1 .5

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/2003

Fct_fN

# X Y

0 1

1 1

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/2004

Fct_fS

# X Y

0 1

1 1

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- This failure model is compatible only with the connection materials, /MAT/LAW59 (CONNECT) and /MAT/LAW83. The connection materials are independent of height, so failure is based on displacement, instead of strain.

- A combined energy failure criteria is

defined as:

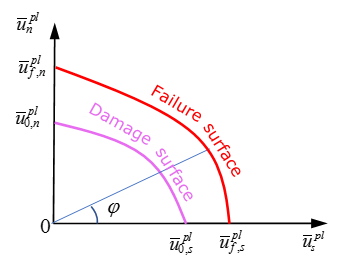

Figure 1.Where, and are the plastic displacement in the normal and tangential directions.

Damage of element begins when the damage surface is reached which is described by:(1) Where, and are the function of fct_ID0N and fct_ID0S. If there are no rate effects, then the curves will be constant.

The damage factor is computed as:(2) And the stress is reduced as:(3) The element is deleted when the rupture surface is reached:(4) With, and being the function of fct_IDFN and fct_IDFS. If there are no rate effects, then the curves will be constant.

-

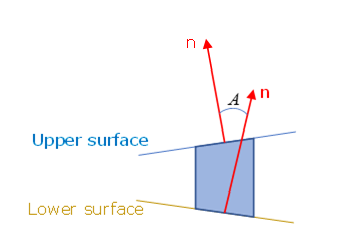

.Where, is the angle between the normal of the lower surface and the normal of the upper surface of the solid element.

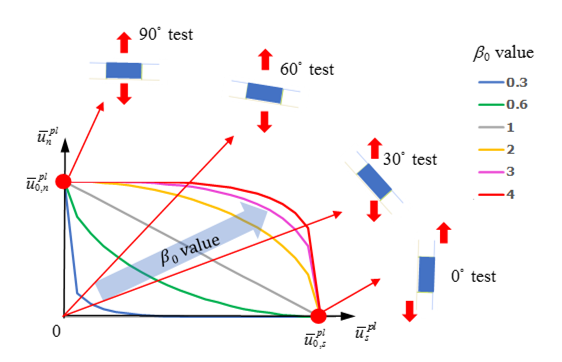

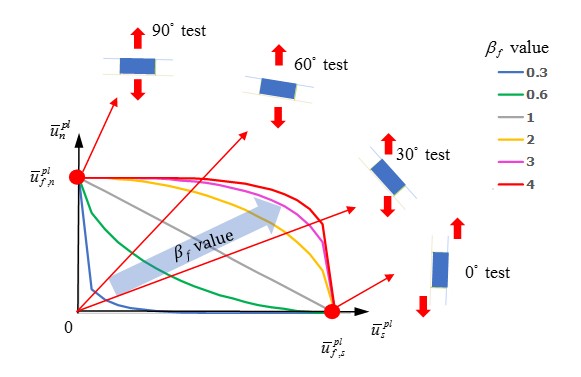

Figure 2. - Parameters are the scale factors used to describe the moment effect (for example, in a peeling test) for damage initiation and failure.

- Parameters

are fitted using a test which combines normal and shear

loards (30° test, 45° test or 60° test, etc.). At least one combined test is needed to

fit the parameters

. Figure 3 and Figure 4

show the effect of

on damage initiation and failure in combined test.

Figure 3. Elongation at Damage Initiation

Figure 4. Elongation at Failure

-

.

- The fail_ID is used with /STATE/BRICK/FAIL and /INIBRI/FAIL. There is no default value. If the line is blank, no value will be output for failure model variables in the /INIBRI/FAIL (written in .sta file with /STATE/BRICK/FAIL option).

- With /ANIM/BRICK/VDAMi following damage variable value could be output in

an animation file:

VDAM1 = d is the damage value, which ranges from [0, 1].

VDAM2 = the damage surface output, which ranges from [0, 1].

VDAM3 = the rupture surface output, which ranges from [0, 1].

- The area is calculated as the mean value of the upper and lower surface of the solid element. If the actual area reaches the value of initial area multiplied by the AREAscale factor, the whole element will be deleted. The default value is set to zero. This causes no deletion, due to area increase. The application is to prevent shooting nodes, if the cohesive element nodes will be released, when surrounding elements start to fail and erode.