/FAIL/JOHNSON

Block Format Keyword Describes the failure criteria by Johnson-Cook failure model.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /FAIL/JOHNSON/mat_ID/unit_ID | |||||||||

| D1 | D2 | D3 | D4 | D5 | |||||

| Ifail_sh | Ifail_so | Dadv | Ixfem | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fail_ID |

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material

identifier (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier (Integer, maximum 10 digits) |

|

| D1 | 1st

parameter. (Real) |

|

| D2 | 2nd

parameter. (Real) |

|

| D3 | 3rd

parameter. (Real) |

|

| D4 | 4th

parameter. (Real) |

|

| D5 | 5th

parameter. (Real) |

|

| Reference strain

rate. (Real) |

||

| Ifail_sh | Shell failure

flag. (Integer) If Ixfem =0: failure - element deleted. If Ixfem =1: failure - element cracked. 2 = 1: (Default) Shell is deleted or cracked when for one integration point or layer. = 2: For each integration point, the stress tensor is set to zero when . The shell is deleted or cracked when for all integration points or layers. |

|

| Ifail_so | Solid failure flag.

(Integer) |

|

| Dadv | Criterion for the crack

advancement (Only active if with Ixfem =1). 4

(Real between 0 and 1) |

|

| Ixfem | XFEM flag (for

/PROP/SHELL,

/PROP/SH_SANDW, and

/PROP/TYPE51 properties only).

(Integer) |

|

| fail_ID | Failure criteria identifier. 3 (Integer, maximum 10 digits) |

Examples

Figure 1.

Example 1 (Steel)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

# MUNIT LUNIT TUNIT

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 1. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/PLAS_JOHNS/1/1

Steel

# RHO_I

7.8E-9 0

# E Nu

210000 .3

# a b n EPS_p_max SIG_max0

270 450 .6 0 0

# c EPS_DOT_0 ICC Fsmooth F_cut Chard

0 0 0 0 0 0

# m T_melt rhoC_p T_r

0 0 0 0

/FAIL/JOHNSON/1/1

# D1 D2 D3 D4 D5

0.11 0.08 -1.5 0 0

# EPS_0 Ifail_sh Ifail_so Dadv Ixfem

1 1 1 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddata

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Example 2 (Steel)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

# MUNIT LUNIT TUNIT

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 1. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/PLAS_JOHNS/1/1

Steel

# RHO_I

7.8E-9 0

# E Nu

210000 .3

# a b n EPS_p_max SIG_max0

270 450 .6 0 0

# c EPS_DOT_0 ICC Fsmooth F_cut Chard

0 0 0 0 0 0

# m T_melt rhoC_p T_r

0 0 0 0

/FAIL/JOHNSON/1/1

# D1 D2 D3 D4 D5

0.11 0.08 -1.5 0 0

# EPS_0 Ifail_sh Ifail_so Dadv Ixfem

1 1 1 0.5 1

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddata

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

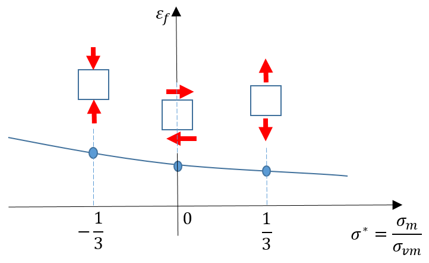

- The parameters are used in stress-strain

relationship:

(2) Where, ( is the stress triaxiality).(3) is computed for all material laws, as:(4) Where,- Tr

- Initial temperature

- Tmelt

- Melting temperature for materials LAW2 and LAW4

When /HEAT/MAT (with Iform =1) references this material model, the values of Tr and Tmelt defined in this card will be overwritten by the corresponding T0 and Tmelt defined in /HEAT/MAT.

- XFEM formulation

(Ixfem=1) is only compatible with BT Q4 (Ishell=1, 2, 3 or 4), and QEPH (Ishell=24) shell elements. If XFEM is

activated (Ixfem=1), the failure criteria will lead to element

cracking instead of element or layer deletion.Two XFEM options are available: mono-layer and multi-layer. The XFEM option depends on the property type associated to the failure criterion applied to the material identifier:

- If /PROP/SHELL (TYPE1) is used, then mono-layer XFEM will be applied.

In this case, the whole element thickness is considered as a single layer. The failure criterion is calculated in each integration point, but only one single crack can appear in this element. This approach is compatible with all values of the shell flag (Ifail_sh=1 or 2). The crack direction is determined by the principal constraints in the last failed integration point.

- If /PROP/SH_SANDW (TYPE11) is used, then multi-layer XFEM will be applied.

In this case, each integration point over thickness is considered as a distinct layer. The failure criterion is calculated separately and the crack direction may be different in each layer. Crack direction in each layer will independently propagate from one element to another. Multi-layer XFEM is not compatible with Ifail_sh=1. Its value will be automatically set to Ifail_sh=2 in this case.- If /PROP/TYPE51 is used, then multi-layer XFEM will

be applied and the separate cracks may appear in each layer and

propagate independently from one element to another. Thus, crack

directions and patterns will be different in each layer. The failure

criterion is calculated separately in each integration point and crack

will propagate when all the integration points fail within a layer.

Multi-layer XFEM is not compatible with

Ifail_sh=1. Its

value will be automatically set to

Ifail_sh=2.Warning: Mono-layer and multi-layer XFEM formulations cannot be mixed in the same model, yet. The choice between them must be made for the whole model.

- The fail_ID is used with /STATE/BRICK/FAIL and /INIBRI/FAIL. There is no default value. If the line is blank, no value will be output for failure model variables in the /INIBRI/FAIL (written in the .sta file with /STATE/BRICK/FAIL option).

- Two different failure (rupture or

crack) are introduced in this failure model. The failure criteria is calculated,

as:

- Element rupture (Ixfem=0):

Element rupture (deleted) if D > 1

- Element crack (Ixfem=1):

Element cracked, if:

this element has no failed neighbors and D > 1, then in this case, new crack initialization in element.

this element has failed neighbors and D > Dadv, then in this case, crack advanced and Dadv is used for crack advancement. Dadv will be used if existing crack arrives to a boundary of an element.

Element deleted, if a second crack arrives to the same element.

Where,(5)

Dadv should always be less than 1.

- Element rupture (Ixfem=0):