J-turn

A J-turn event simulates a vehicle response to a large steer in one direction, a dwell time to allow the vehicle to react, and a large steer in the opposite direction, with an additional reaction time. The event is used to characterize the stability of vehicles. Both steer directions can be run by reversing the sign of the steering inputs. A drive torque controller is used to maintain a constant speed and standard outputs for the vehicle and tires are included in the tire system and the output requests system. A plot template is available to plot the results.

A better name for the event is Fishhook maneuver. The event is designed to be able to simulate the NHTSA fishhook test as described in DOT publication DOT HS 809 705, “Phase VIII of NHTSA’s Light Vehicle Rollover Research Program-A Demonstration of the Dynamic Tests Developed for NHTSA’s NCAP Rollover Rating System”.

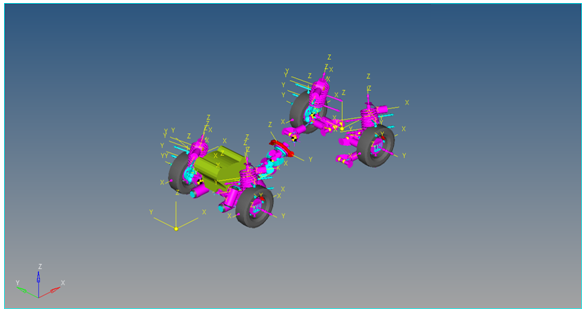

Figure 1. J-turn Event

This event is designed to work with a full vehicle model that has been built through the MotionView Assembly Wizard. The event should attach to the model automatically when added through the Task Wizard. It can be used with models built manually, as long as the attachment scheme in the event is strictly followed.

The event is better described as the Fishhook test. The J-turn can be run by setting the second steer angle to zero. The event setup and sequence is described below. The default values in the event form represent a very mild input to the vehicle. Steer angles of 360 degrees and steering input rates over 300 deg/sec are typically seen in published literature regarding the J-turn. To match the input parameters to the NHTSA test specification, you must measure the parameters from the other vehicle characterization tests.

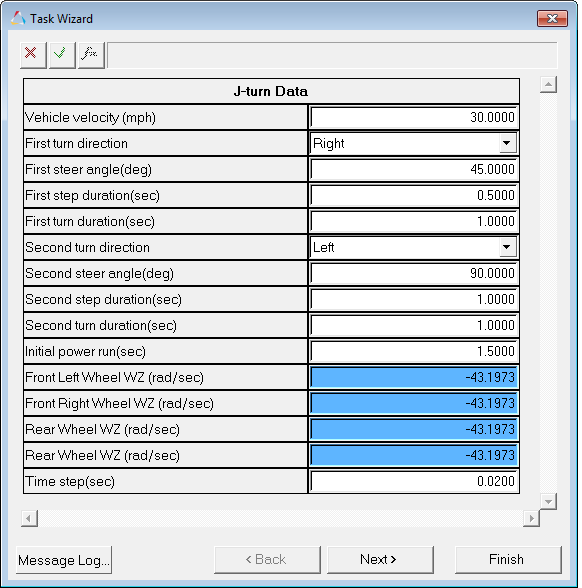

Figure 2. J-turn Data Dialog

| Input | Units | Description |

|---|---|---|

| Vehicle Velocity | MPH | Initial vehicle velocity. |

| First Turn Direction | Right or Left | Not used. |

| First Steer Angle | Degrees | Angle in degrees of the initial steer input. A positive number turns the vehicle right and a negative number turns the vehicle left. |

| First Step Duration | Seconds | Time required to input the first steer angle. The step function is used to input the angle to the steering wheel. |

| First Turn Duration | Seconds | Time the steering is held fixed at the first steer angle. |

| Second Turn Direction | Right or Left | Not used. |

| Second Steer Angle | Degrees | Angle in degrees of the second steer input. A positive number turns the vehicle left and a negative number turns the vehicle right. |

| Second Step Duration | Seconds | The time required to input the second steer angle. A step function is used to input the angle and uses the second turn duration and second steer angle as inputs. |

| Second Turn Duration | Seconds | The time the vehicle steering is held at the Second steer angle input. The event ends 1.5 seconds after the second turn duration time occurs. |

| Initial Power Run | Seconds | The time at the beginning of the event. This time is typically used to verify the vehicle is at a steady state velocity. The event has an additional 0.5 seconds of fixed time added at the start of the event. |

| Front Left Wheel WZ | Rad/Sec | Right front wheel rotational speed. Do not modify this because it is a calculated value. |

| Front Right Wheel WZ | Rad/Sec | Left front wheel rotational speed. Do not modify this because it is a calculated value. |

| Rear Wheel WZ | Rad/Sec | Right rear wheel rotational speed. Do not modify this because it is a calculated value. |

| Rear Wheel WZ | Rad/Sec | Left rear wheel rotational speed. Do not modify this because it is a calculated value. |

| Time Step | Seconds | Output data time step. Data is written to the output files every time step seconds. |

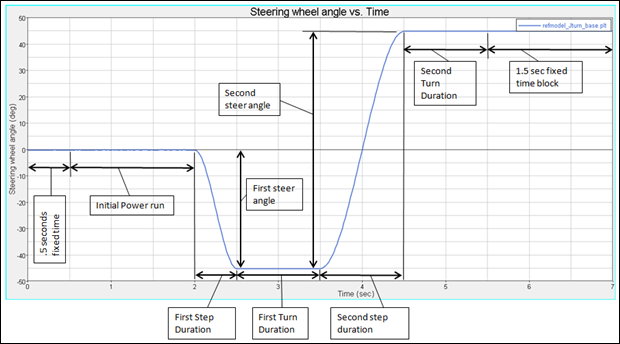

Figure 3.

The event sequence is as follows:

| Time | Label | Description |

|---|---|---|

| 0 | Statics | Static analysis is performed on a vehicle fixed to ground. |

| 0+ | Joint release | Two joints holding the vehicle to ground are released; the joint holding each wheel to the spindle is released. |

| 0++ | Begin dynamics | Dynamic simulation begins. The steering wheel follows the input defined by the J-turn Steer Motion solver variable. |

| .5 + Initial Power run | Start first steer event | The initial steer input begins. The step function rotates the steering wheel from 0 to the first steer angle in the first step duration time. |

| + first step duration | End first steer event/begin first steer hold | The initial steer event is complete and the first turn duration time begins. The steering wheel is held at the first steer angle input. |

| +First turn duration | Steer hold complete/ begin second step input | Steering hold is complete and the second steering input begins. The second steering input is done as a step function using the second steer angle and the second step duration as inputs. |

| +second step duration | Second steer input complete | The second steer input is complete and the wheel is now held fixed for the second step duration time. Note that the resulting steer angle is the net angle of the first and second input. |

| +second turn duration | Second steer hold is complete | Steering is held fixed for the second turn duration time period. |

| +1.5 sec | Vehicle reaction time | Steering is held fixed. |

| Event end | End | Event ends. |

- The first turn direction and second turn direction parameters are not used by the event. Change the sign of the first steer angle and second steer angle to reverse the steer direction.

- The event can be run parametrically using HyperStudy.

- No road surface graphic representation is included in the event. The vehicle runs on a flat road surface that is defined using the .rdf file in the tire system.

Six types of modeling element containers are used to define the event. Two sub-systems (output requests and a drive torque controller) are also included in the event.

Datasets

One dataset is used in the system and it contains the data used to describe the J-turn event. The event allows you to set turn directions and timing for the two steering inputs that define the J-turn. The wheel WZ (initial rotational velocities) are calculated values and should not be changed.

Forms

The form is the only place that you should change the data of the event. The timing and magnitude of the steer inputs can be changed on the form. The wheel WZ values are calculated using the initial speed entered on the event form and the tire rolling radius from the tire system form.

Joints

A ball joint is included in the J-turn event. The joint attaches a dummy body to the steering rack. The joint is included to make certain events work in ADAMS. Attach the dummy body to the steering rack if building a model manually.

Motions

Three motions are included in the event. The steering motion to the vehicle is provided by the steering controller and acts on a revolute joint that connects the steering column to the vehicle body. If a steering column is not included in the model, the joint acts between the steering rack input shaft and the vehicle body.

The front and rear wheel motions act on the wheel spindle revolute joints that connect the wheel hub to the knuckle. The motion is initially zero (fixing the wheels to the knuckle) so the model converges statically. The motions are deactivated after the static equilibrium analysis to allow the tires to rotate.

Solver Variables

The J-turn event consists of only one solver variable, the J-turn Steer Motion Solver variable. The solver variable is the steering wheel input motion function. The function is created using the inputs from the event form and is assigned as the steering motion input in the event template.

Templates

A template is included in the J-turn event task. The template is solver specific and only the MotionSolve template is documented. The template is inserted in the solver deck after the </Model> command and controls the execution of the event.

<ResOutput

angle_type = "YPR"

/>

<ResOutput

mrf_file = "TRUE"

/>

<ResOutput

plt_file = "TRUE"

/>

<H3DOutput

switch_on = "TRUE"

increment = "1"

/>

<ResOutput

abf_file = "TRUE"

/>

{if (tire_dataset.opt_omega.ival ==1)}

<!--Initial static analysis -->

<Simulate

analysis_type = "Static"

end_time = "0.0"

/>

{endif}References

ISO +7401-2003 – Road Vehicles-Lateral transient response test methods-Open-loop test methods.