CRASURV Formulation (Iform= 1)

Block Format Keyword This law describes the composite shell and solid material using the CRASURV formulation.

This material is assumed to be orthotropic-elastic before the Tsai-Wu criterion is reached. The material becomes nonlinear afterwards. For solid elements, the material is assumed to be linearly elastic in the transverse direction. The Tsai-Wu criterion can be set dependent on the plastic work and strain rate in each of the orthotropic directions and in shear to model material hardening. Strain and plastic energy criterion for brittle damage and failure is available. A simplified delamination criterion based on out-of-plane shear angle can be used.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW25/mat_ID/unit_ID or /MAT/COMPSH/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E11 | E22 | Iform | E33 | ||||||

| G12 | G23 | G31 | |||||||

| dmax | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Ioff | WP_fail | ratio | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| c | α | ICCglobal | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| d3max | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Fsmooth | Fcut | ||||||||

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial density. (Real) |

||

| E11 | Young's modulus in direction

1. (Real) |

|

| E22 | Young's modulus in direction

2. (Real) |

|

| Poisson's ratio . (Real) |

||

| Iform | Formulation flag. 1

(Integer) |

|

| E33 | Young's modulus in direction 33. 2 (Real) |

|

| G12 | Shear modulus in direction

12. (Real) |

|

| G23 | Shear modulus in direction

23. (Real) |

|

| G31 | Shear modulus in direction

31. (Real) |

|

| Maximum tensile strain for element

deletion in material direction 1. Default = 1.2 x 1020 (Real) |

||

| Maximum tensile strain for element

deletion in material direction 2. Default = 1.2 x 1020 (Real) |

||

| Tensile failure strain in the material

direction 1 at which stress starts to reduce. 4 Default = 1.0 x 1020 (Real) |

||

| Maximum tensile strain in material

direction 1 at which the stress in the element is set to a value

dependent on dmax. 4 Default = 1.1 x 1020 (Real) |

||

| Tensile failure strain in the material

direction 2 at which stress starts to reduce. Default = 1.0 x 1020 (Real) |

||

| Maximum tensile strain in material

direction 2 at which the stress in the element is set to a value

dependent on dmax. Default = 1.1 x 1020 (Real) |

||

| dmax | Maximum damage factor (dmax < 1). 4 Default = 0.999 (Real) |

|

| Global maximum plastic work per unit

shell volume. Default = 1020 (Real) |

||

| Ioff | Flag that controls shell and thick

shell element deletion depending on failure modes in the element

layers. 4

(Integer) |

|

| WP_fail | Directional maximum plastic work

failure formulation. 5

|

|

| Ratio | Ratio parameter which controls the

deletion of shell elements based on the number of failed layers.

4

Default = 1.0 (Real) |

|

| c | Global strain rate coefficient for

plastic work criteria.

(Real) |

|

| Reference strain

rate. (Real) |

||

| α | Reduction factor for

F12 coefficient calculation in

Tsai-Wu criterion. Default set to 1.0 (Real) |

|

| ICCglobal | Global strain rate effect flag.

4

(Integer) |

|

| Yield stress in tension in

direction 1. Default = 0.0 (Real) |

||

| Plastic hardening

parameter in tension in direction 1. Default = 0.0 (Real) |

||

| Plastic hardening exponent

in tension in direction 1. Default = 1.0 (Real) |

||

| Maximum stress in tension

in direction 1. Default = 1020 (Real) |

||

Strain rate coefficient in tension

in direction 1.

Default = c (Real) |

||

| Initial softening strain in tension in

the material direction 1. Default = 1.0 x 1020 (Real) |

||

| Maximum softening strain in tension in

the material direction 1. Default = (Real) |

||

| Residual stress in tension in direction

1. Default = (Real) |

||

| Directional maximum plastic work per

unit shell volume in tension in direction 1. 4 Default = 1020 (Real) |

||

| Yield stress in tension in

direction 2. Default = 0.0 (Real) |

||

| Plastic hardening

parameter in tension in direction 2. Default = 0.0 (Real) |

||

| Plastic hardening exponent

in tension in direction 2. Default = 1.0 (Real) |

||

| Maximum stress in tension

in direction 2. Default = 1020 (Real) |

||

Strain rate coefficient in tension

in direction 2.

Default = c (Real) |

||

| Initial softening strain in tension in

the material direction 2. Default = 1.0 x 1020 (Real) |

||

| Maximum softening strain in tension in

direction 2. Default = (Real) |

||

| Residual stress in tension in direction

2. Default = (Real) |

||

| Directional maximum plastic work per

unit shell volume in tension in direction 2. 4 Default = 1020 (Real) |

||

| Yield stress in compression in

direction 1. Default = 0.0 (Real) |

||

| Plastic hardening parameter in

compression in direction 1. Default = (Real) |

||

| Plastic hardening exponent in

compression in direction 1. Default = (Real) |

||

| Maximum stress in compression in

direction 1. Default = 1020 (Real) |

||

Strain rate coefficient in

compression in direction 1.

Default = c (Real) |

||

| Initial softening strain in compression

in the material direction 1. Default = 1.0 x 1020 (Real) |

||

| Maximum softening strain in compression

in the material direction 1. Default = (Real) |

||

| Residual stress in compression in

direction 1. Default = (Real) |

||

| Directional maximum plastic work per

unit shell volume in compression in direction 1. Default = 1020 (Real) |

||

| Yield stress in compression in

direction 2. Default = 0.0 (Real) |

||

| Plastic hardening parameter in

compression in direction 2. Default = (Real) |

||

| Plastic hardening exponent in

compression in direction 2. Default = (Real) |

||

| Maximum stress in compression in

direction 2. Default = 1020 (Real) |

||

Strain rate coefficient in

compression in direction 2.

Default = c (Real) |

||

| Initial softening strain in compression

in the material direction 2. Default = 1.0 x 1020 (Real) |

||

| Maximum softening strain in compression

in the material direction 2. Default = (Real) |

||

| Residual stress in compression in

direction 2. Default = (Real) |

||

| Directional maximum plastic work per

unit shell volume in compression in direction 2. 4

Default = 1020 (Real) |

||

| Yield stress in direction 12 (in 45

degree of fiber direction). Default = 0.0 (Real) |

||

| Plastic hardening parameter in

direction 12. Default = (Real) |

||

| Plastic hardening exponent in direction

12. Default = (Real) |

||

| Maximum stress in direction

12. Default = 1020 (Real) |

||

Strain rate coefficient in direction

12.

Default = c (Real) |

||

| Initial softening strain in the

material direction 12. Default = 1.0 x 1020 (Real) |

||

| Maximum softening strain in the

material direction 12. Default = (Real) |

||

| Residual stress in direction

12. Default = (Real) |

||

| Directional maximum plastic work per

unit shell volume in direction 12. 4

Default = 1020 (Real) |

||

| Out of plane shear strain when

delamination begins. 4 Default = 1020 (Real) |

||

| Out of plane shear strain when

delamination ends, and the element is deleted. 4 Default = 1.1e20 (Real) |

||

| d3max | Maximum delamination damage factor

(d3max < 1). 4 Default = 1.0 (Real) |

|

| Fsmooth | Strain rate smoothing flag.

(Integer) |

|

| Fcut | Cutoff frequency for strain rate

smoothing. Default = 1020 (Real) |

Example (Carbon composite)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

g mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/COMPSH/1/1

carbone based tissu

# RHO_I

.0015 0

# E11 E22 NU12 Iform E33

56275 54868 .042 1 0

# G12 G23 G31 EPS_f1 EPS_f2

4212 4212 4212 0 0

# EPS_t1 EPS_m1 EPS_t2 EPS_m2 d_max

.016305 .02 .014131 .016 0

# Wpmax Ioff WP_fail ratio

15 6 0 .5

# c EPS_rate_0 alpha ICC_global

0 0 0 0

# sig_1yt b_1t n_1t sig_1maxt c_1t

917.59 0 1 919 0

# EPS_1t1 EPS_2t1 SIGMA_rst1 Wpmax_t1

0 0 0 0

# sig_2yt b_2t n_2t sig_2maxt c_2t

775.38 0 1 777 0

# EPS_1t2 EPS_2t2 sig_rst2 Wpmax_t2

0 0 0 0

# sig_1yc b_1c n_1c sig_1maxc c_1c

355 .17 .84 708.87 0

# EPS_1c1 EPS_2c1 sig_rsc1 Wpmax_c1

.0226 .025 0 0

# sig_2yc b_2c n_2c sig_2maxc c_2c

355 .17 .84 702.97 0

# EPS_1c2 EPS_2c2 sig_rsc2 Wpmax_c2

.0226 .025 0 0

# sig_12y b_12 n_12 sig_12max c_12

30 2.872290896763 .3 132.57 0

# EPS_1_12 EPS_2_12 sig_rs_12 Wpmax_12

0 0 0 0

# GAMMA_ini GAMMA_max d3_max

0 0 0

# Fsmooth Fcut

0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Example (Kevlar)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/COMPSH/1/1

KEVLAR

# RHO_I

1.4E-9

# E11 E22 NU12 Iform E33

87000 87000 .3 1 0

# G12 G23 G31 EPS_f1 EPS_f2

2200 2200 2200 0 0

# EPS_t1 EPS_m1 EPS_t2 EPS_m2 d_max

.015 .017 .015 .017 0

# Wpmax Ioff WP_fail ratio

0 6 0 .5

# c EPS_rate_0 alpha ICC_global

0 0 0 0

# sig_1yt b_1t n_1t sig_1maxt c_1t

650 0 1 0 0

# EPS_1t1 EPS_2t1 SIGMA_rst1 Wpmax_t1

0 0 0 0

# sig_2yt b_2t n_2t sig_2maxt c_2t

650 0 1 0 0

# EPS_1t2 EPS_2t2 sig_rst2 Wpmax_t2

0 0 0 0

# sig_1yc b_1c n_1c sig_1maxc c_1c

335 0 1 650 0

# EPS_1c1 EPS_2c1 sig_rsc1 Wpmax_c1

.02 0 0 0

# sig_2yc b_2c n_2c sig_2maxc c_2c

160 0 0 650 0

# EPS_1c2 EPS_2c2 sig_rsc2 Wpmax_c2

.03 0 0 0

# sig_12y b_12 n_12 sig_12max c_12

50 0 0 100 0

# EPS_1_12 EPS_2_12 sig_rs_12 Wpmax_12

0 0 0 0

# GAMMA_ini GAMMA_max d3_max

0 0 0

# Fsmooth Fcut

0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- The formulation flag

Iform should be set to 1, for

the CRASURV (crash survivability) formulation. Compare with

Iform=0, in this

formulation:

- The F variable coefficients of is function of plastic work and strain rate

- It allows the simulation of the ductile failure of orthotropic shells

- Considering different plastic and failure behaviors in tension, in compression and in shear

- Usage with property

and element type.

- This material requires orthotropic shell properties (/PROP/TYPE9 (SH_ORTH), /PROP/TYPE10 (SH_COMP) or /PROP/TYPE11 (SH_SANDW)). These properties specify the orthotropic direction, therefore, it is not compatible with the isotropic shell property (/PROP/TYPE1 (SHELL)). Property /PROP/SH_ORTH is not compatible with the CRASURV formulation.

- This material is available with under-integrated Q4 (Ishell= 1,2,3,4) and fully integrated BATOZ (Ishell=12) shell formulations.

- This material is compatible with orthotropic solid property (/PROP/SOL_ORTH), the orthotropic thick shell property (/PROP/TSH_ORTH) and the composite thick shell property (/PROP/TSH_COMP). These properties specify the orthotropic directions. It is assumed that, for solids and thick shells, the material is elastic and the E33 value must be set in such cases.

- Failure criterion in LAW25 is not applicable to solid elements. To determine failure for solid elements /FAIL card should be used.

- For shell and thick shell composite parts, with /PROP/SH_COMP, /PROP/SH_SANDW, /PROP/TSH_ORTH or /PROP/TSH_COMP, material is defined directly in the property card. The failure criteria defined within this material (for example, LAW25) are accounted for. Material referred to in the corresponding /PART card is not used.

- The Tsai-Wu

criterion:The material is assumed to be elastic until the Tsai-Wu criterion is fulfilled:

- If : Elastic

- If : Nonlinear

Where, is stress in element for Tsai-Wu criterion, is computed as:(1) Here, , and are the stresses in the material coordinate system.

The F variable coefficients of for Tsai-Wu criterion is functions of plastic work and is determined as:(2) (3) (4) (5) Where, =1 or 2.

The values of the limiting stresses when the material becomes nonlinear in directions 1, 2 or 12 (shear) are modified based on the values of plastic work and strain rate, as:

In tension:(6) Where, =1 or 2.

In compression:(7) Where, =1 or 2.

In shear:(8) The superscripts and represent compression and tension, respectively.

Plastic work in above limiting stress is defined as:(9) Where, is unit reference plastic work per volume.

This criterion represents a second order closed three-dimensional Tsai-Wu surface in , and space. This surface is scaled, moved and rotated due to the variation of plastic work and true strain rate.Note: For shear, the parameters determining nonlinear behavior are the same in tension and compression. - Damage with tensile

strain and energy failure.This material could describe in plane and out-of-plane damage.

- In plane damage with damage factor

Global tensile strain damage between and controlled by the damage factor , which is given by:

in directions, i = 1, 2

- E-modulusE-modulus is reduced according to damage parameter if, :

(10) E-modulus is reduced according to damage paramter, if :(11) In this case, damage is set to and it is not updated further.

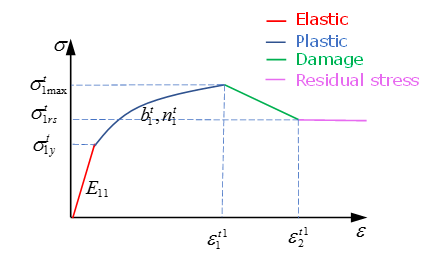

- Yield StressYield stress is reduced since below damage strain in different loading:

- and in tension

- and in compression

- and in shear

For example, tensile in direction 1 will be reduced when at and until residual stress at .

Figure 1. Tensile in Direction 1 - Element deletion is controlled by the Ioff flag.

Out-of-plane damage (delamination) with .

The simpliest delamination criterion is based on the evaluation of out-of-plane shear strains ( and ) with .- Element stresses and are gradually reduced if,

- The element is completely removed (fails), if in one of the shell layers.

- In plane damage with damage factor

- Element rupture with

strain, damage and energy failure criterion.

- Element rupture (stress set to zero) depends on the option

WP_fail where either theglobal maximum plastic

work

or directional maximum plastic work

will be taken into account. When the

stress value of all layers is zero, the element is deleted.

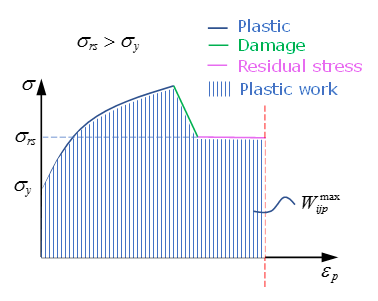

- If WP_fail=0

- If the residual stress is greater than yield stress ( ), then the element layer ruptures (stress set to zero) if it reaches the directional maximum plastic work . Example, tensile loading in direction 1 with , element layer ruptured if plastic work reach .

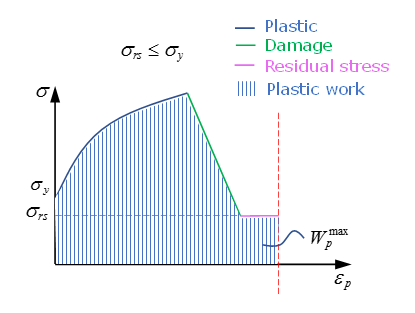

- If WP_fail=1

- The element layer ruptures when it reaches the directional maximum plastic work in its direction even if the residual stress is less than the yield stress.

- Element deletion is controlled by the option Ioff which uses the

following criteria or combinations of criteria.

- Element rupture could be due to reaching the strain criterion ( in direction )

- Damage criterion ( in direction )

- Plastic work failure criterion

Note:- When using the plastic work failure criterion WP_fail, if a directional maximum plastic work is not entered, then the global maximum plastic strain will be taken.

- Similarly, when

ICCglobal=4,

the global maximum plastic work or directional maximum

plastic work will be scaled based on strain rate.For example, with a tensile loading in direction 2, the maximum plastic work values are scaled:

(12) and(13)

- Element rupture (stress set to zero) depends on the option

WP_fail where either theglobal maximum plastic

work

or directional maximum plastic work

will be taken into account. When the

stress value of all layers is zero, the element is deleted.

- The ratio field can be used to provide stability to composite shell components. For example, it allows you to delete unstable elements wherein, all but one layer has failed. This last layer may cause instability during simulation due to a low stiffness value. This option is available for strain and plastic energy based brittle failure.

- Tensile strain and energy failure criterion of LAW25 is not available for orthotropic shells with /PROP/TYPE9.

- The unit of

is energy per unit of volume. If set

as default value (0) is encountered, the default

value is 1 unit of the model.Example:

- If unit system of kg-m-s used in model, then

- If unit system of Ton-mm-s used in model, then

For proper conversion of this value if changing units in pre- and post-processor, it is advised to replace the default value by the true value “1”, so that the value of will be automatically converted. Leaving the field to “0” may result in errors in case of automatic conversion.Note: A local unit system can be created for the material to avoid conversion. - Output for

post-processing:

- To post-process this material in the animation file, the following

Engine cards should be used:

- /ANIM/SHELL/WPLA/ALL for plastic work output

- /ANIM/BRICK/WPLA for plastic work output

- /ANIM/SHELL/TENS/STRAIN for strain tensor output in the elemental coordinate system

- /ANIM/SHELL/TENS/STRESS for stress tensor output in the elemental coordinate system

- /ANIM/SHELL/PHI angle between elemental and first material direction

- /ANIM/SHELL/FAIL number of failed layers.

- To post-process this material in the time-history file, the following

definitions in /TH/SHEL or

/TH/SH3N card should

be used:

- PLAS (or EMIN and EMAX) for minimum and maximum plastic work in the shell.

- WPLAYJJ (JJ=0 to 99) for plastic work in a corresponding layer.

- The output file (*0001.out) displays some

information when the failure criteria is met:

- Failure 1 and 2 means tensile failure direction 1 or 2, respectively

- Failure

-Pmeans global plastic work failure P-T1/P-T2means plastic work failure in tension direction 1 or 2, respectivelyP-C1/P-C2means plastic work failure in compression direction 1 or 2, respectivelyP-T12means plastic work failure in shear

The failure message also indicates which element and which layer is affected. It is output when the failure criteria is met for an integration point. As Batoz elements have 4 integrations points for each layer, this message may be output up to 4 times per layer and elements in this case.

- To post-process this material in the animation file, the following

Engine cards should be used:

- /VISC/PRONY can be used with this material law to include viscous effects.