/MAT/LAW12 (3D_COMP)

Block Format Keyword This law describes a solid material using the Tsai-Wu formulation that is usually used to model composites. This material is assumed to be 3D orthotropic-elastic before the Tsai-Wu criterion is reached.

The material becomes nonlinear afterwards. The Tsai-Wu criterion can be set dependent on the plastic work and strain rate in each of the orthotropic directions and in shear to model material hardening. Stress based orthotropic criterion for brittle damage and failure is available. This material is a generalization and improvement of /MAT/LAW14 (COMPSO).

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW12/mat_ID/unit_ID or /MAT/3D_COMP/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E11 | E22 | E33 | |||||||

| G12 | G23 | G31 | |||||||

| B | n | fmax | |||||||

| Ef | c | ||||||||

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material

identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material

title. (Character, maximum 100 characters) |

|

| Initial density. (Real) |

||

| E11 | Young's modulus in direction

1. (Real) |

|

| E22 | Young's modulus in

direction 2. (Real) |

|

| E33 | Young's modulus in

direction 3. (Real) |

|

| Poisson's ratio between

directions 1 and 2. (Real) |

||

| Poisson's ratio between

directions 2 and 3. (Real) |

||

| Poisson's ratio between

directions 3 and 1. (Real) |

||

| G12 | Shear modulus in direction

12. (Real) |

|

| G23 | Shear modulus in direction

23. (Real) |

|

| G31 | Shear modulus in direction

31. (Real) |

|

| Stress at the beginning of

composite tensile/compressive failure in direction 1. 4 Default = 1030 (Real) |

||

| Stress at the beginning of

composite tensile/compressive failure in direction 2. 4 Default = (Real) |

||

| Stress at the beginning of

composite tensile/compressive failure in direction 3. 4 Default = (Real) |

||

| Maximum damage factor.

4 Default = 0.05 (Real) |

||

| B | Global plastic hardening

parameter. 3 (Real) |

|

| n | Global plastic hardening

exponent. Default = 1.0 (Real) |

|

| Maximum value of the

Tsai-Wu criterion limit. 3 Default = 1010 (Real) |

||

| Reference plastic work per

unit solid volume. Default = 1.0 (in local unit system) (Real) |

||

| Yield stress in tension in

direction 1. 3 Default = 0.0 (Real) |

||

| Yield stress in tension in

direction 2. Default = 0.0 (Real) |

||

| Yield stress in

compression in direction 1. Default = 0.0 (Real) |

||

| Yield stress in

compression in direction 2. Default = 0.0 (Real) |

||

| Yield stress in tensile

shear in direction 12. Default = 0.0 (Real) |

||

| Yield stress in

compressive shear in direction 12. Default = 0.0 (Real) |

||

| Yield stress in tensile

shear in direction 23. Default = 0.0 (Real) |

||

| Yield stress in

compressive shear in direction 23. Default = 0.0 (Real) |

||

| α | Fiber volume fraction.

5 (Real) |

|

| Ef | Fiber Young's modulus.

5 (Real) |

|

| c | Global strain rate coefficient.

(Real) |

|

| Reference strain

rate. (Real) |

||

| ICC | Strain rate effect flag.

3

(Integer) |

Example (Carbon)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW12/1/1

carbon

# RHO_I

1.5E-9

# E11 E22 E33

64000 60000 5000

# NU12 NU23 NU31

.07 .07 .07

# G12 G23 G31

4000 2000 2000

# sigma_t1 sigma_t2 sigma_t3 delta

0 0 0 0

# B n fmax Wpref

50 .5 0 0

# sigma_1yt sigma_2yt sigma_1yc sigma_2yc

600 500 600 600

# sigma_12yt sigma_12yc sigma_23yt sigma_23yc

100 100 30 30

# sigma_3yt sigma_3yc sigma_13yt sigma_13yc

50 50 100 100

# alpha Ef c EPS_RATE_0 ICC

0 0 0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- This material requires an orthotropic solid property (/PROP/TYPE6 (SOL_ORTH), /PROP/TYPE21 (TSH_ORTH), or /PROP/TYPE22 (TSH_COMP). It can only be used with solid elements for a 3-dimensional analysis. This law is compatible with 10-node tetrahedron and 4-node tetrahedron elements. The orthotropic material directions are set in the property entries.

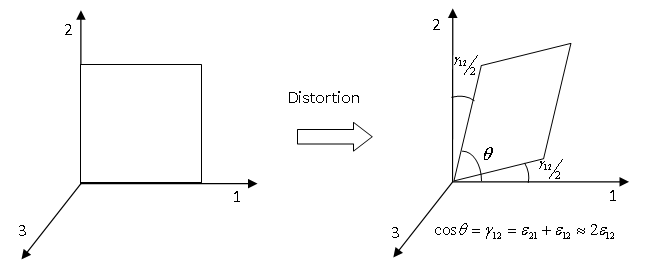

- Stress-strain relation in

elastic phase.The stresses and strains are related as:

(1) (2) (3) (4) Where,- Strains

- Stresses

- , and

- Distortions in the corresponding material directions

Figure 1. - Tsai-Wu criterion:The material is assumed to be elastic until the Tsai-Wu criterion is fulfilled. After exceeding the Tsai-Wu criterion limit , the material becomes nonlinear:

- If : elastic

- If : nonlinear

Where,- Stress

in element for Tsai-Wu criterion

computed as:

(5)

The coefficients of the Tsai-Wu criterion are determined from the limiting stresses when the material becomes nonlinear in directions 1, 2, 3 or 12, 23, 31 (shear) in compression or tension as:-

is the variable Tsai-Wu criterion

limit defined:

(6) Where,- Reference plastic work

- Relative plastic work

- Plastic hardening parameter

- Plastic hardening exponent

- Reference true strain rate

- Strain rate coefficient

the maximum value of the Tsai-Wu criterion limit depends on ICC:- If ICC=1

- If ICC=2

Where,

- Stress damage:When the limiting stress value of is reached in tension, the corresponding stress value is scaled as . The value of damage is updated on each time step with incremental damage parameter .

(7) After reaches the value of 1, the stress in corresponding direction is set to 0. The damage is irreversible, that is, if a value of is attained the material will not reach any lower damage value.

- Fiber reinforcement:

These parameters allow you to define additional fiber reinforcement in the 11 direction. Additional stress in direction 11 will be added equal to .