/PROP/TYPE12 (SPR_PUL)

Block Format Keyword The pulley spring property set (with one translational DOF) is used to model a pulley.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /PROP/TYPE12/prop_ID/unit_ID or /PROP/SPR_PUL/prop_ID/unit_ID | |||||||||

| prop_title | |||||||||

| Mass | sens_ID | Isflag | Ileng | Fric | |||||

| K1 | C1 | A1 | B1 | D1 | |||||

| fct_ID11 | H1 | fct_ID21 | fct_ID31 | fct_ID41 | |||||

| F1 | E1 | Ascale1 | Hscale1 | ||||||

| fct_IDfr | Ifr | Yscale_F | Xscale_F | F_min | F_max | ||||

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| prop_ID | Property identifier (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier (Integer, maximum 10 digits) |

|

| prop_title | Property title (Character, maximum 100 characters) |

|

| Mass | Mass.

(Real) |

or |

| sens_ID | Sensor

identifier. (Integer) |

|

| Isflag | Sensor flag. 4

5

(Integer) |

|

| Ileng | Input per unit length flag.

(Integer) |

|

| Fric | Coulomb friction. 6 (Real) |

|

| K1 | Stiffness

with Ileng= 0.

(Real) |

|

Stiffness

with Ileng= 1.

(Real) |

||

| C1 | Damping

with Ileng= 0. (Real) |

|

| Damping

with Ileng= 1. (Real) |

||

| A1 | Coefficient for strain rate effect in

tension (homogeneous to a force). Default = 1.0 (Real) |

|

| B1 | Logarithmic coefficient for strain rate

effect in tension (homogeneous to a force). (Real) |

|

| D1 | Scale coefficients for elongation

velocity. Default = 1.0 (Real) |

|

| fct_ID11 | Stiffness function identifier defining

with Ileng= 0 or

with Ileng= 1.

(Integer) |

|

| H1 | Hardening flag for nonlinear spring.

(Integer) |

|

| fct_ID21 | Function defining the change in force

with spring displacement (or rotation) rate in

with Ileng= 0 or

with Ileng=1. (Integer) |

|

| fct_ID31 | Function used only for unloading. If H1=4: Function identifier defining lower yield curve. If H1=5: Function identifier defining residual displacement vs maximum displacement. If H1=6: Function identifier defining nonlinear unloading curve. If H1=7: Function identifier defining nonlinear unloading curve. (Integer) |

|

| fct_ID41 | Function to consider velocity or

deformation velocity dependency damping in

with Ileng= 0 or

with Ileng=1. (Integer) |

|

| Negative failure displacement (if Ileng=0), or Negative failure displacement multiply if Ileng=1). Default = -1030 (Real) |

||

| Positive failure displacement (if Ileng=0), or Positive failure displacement multiply if Ileng=1). Default = 1030 (Real) |

||

| F1 | Scale factor for

or

(abscissa of fct_ID21 function

for

or

). (Real) |

|

| E1 | Scale factor for

or

(fct_ID21 function) which is coefficient for strain

rate effect (homogeneous to a force). (Real) |

|

| Ascale1 | Scale factor for

or

(abscissa of fct_ID11 function

for

or

). (Real) |

|

| Hscale1 | Scale factor for

or

(fct_ID41 function) homogeneous to a

force. Default = 1.0 (Real) |

|

| fct_IDfr | Function identifier defining scaling of

friction coefficient Fric as function of force difference

between left and right arms of the pulley. (Integer) |

|

| Ifr | Friction model flag. 6

(Integer) |

|

| Yscale_F | Ordinate scale for function

fct_IDfr. Default = 1.0 (Real) |

|

| Xscale_F | Abscissa scale for function

fct_IDfr. Default = 0.0 (Real) |

|

| F_min | Negative limit force for non-reversible

friction model. Used only for Ifr = 1. 6 Default = -1030 (Real) |

|

| F_max | Positive limit force for non-reversible

friction model. Used only for Ifr = 1. 6 Default = 1030 (Real) |

Example

/UNIT/2

unit for prop

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/PROP/SPR_PUL/1/2

pulley spring example with friction

# Mass sensor_ID Isflag Ileng Fric

2.7e-5 0 0 0 1

# K C A B D

10000 .001 0 0 0

#funct_ID1 H funct_ID2 funct_ID3 funct_ID4 delta_min delta_max

1 0 0 0 0 0 0

# Fscale1 E Ascalex H4

0 0 0 0

# Fct_IDfr Ifr Yscale_F Xscale_F F_MIN F_MAX

2 1 0 0 -800 4500

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/1

non-linear elastic

# Disp. Force

# X Y

-1 -0.1

0 0

1 10000

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/2

friction function

# Force Fric

# X Y

-1000 0.2

1000 0.2

2000 0.3

4000 0.9

5000 1.0

10000 1.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATAComments

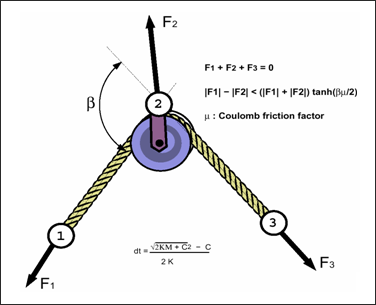

- This property is modeled using

a 3 node /SPRING element where node 1 and node 3 are the ends of the

rope and node 2 is the pully location.

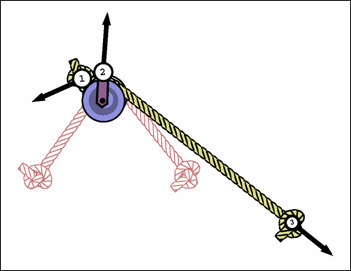

Figure 1.Once node 1 slides to node 2 locking occurs as if there is a knot at node 1 that cannot move through the pully.

Figure 2. - Force computation:

- In case of Ileng =0 (flag Ileng is defined in Line 3), the force

in the spring is computed as:

(1) With

Where, is the difference between the current length and the initial length of the spring element.

- If Ileng=1, all input are per unit length.

Spring mass =

Spring stiffness =

Spring damping =

Spring inertia =

Where, is the spring reference length.

- The value of force in the spring is computed as:

(2) Where, is the engineering strain:(3) Force functions are given versus engineering strain and engineering strain rate.

Failure criteria are defined with respect to strain. Input of negative/positive failure limit should be related to initial length

- In case of Ileng =0 (flag Ileng is defined in Line 3), the force

in the spring is computed as:

- If (resp ) is 0, no failure in the direction. The must be negative. For linear springs, and are null functions and A1, B1 and E1 are not taken into account.

- Spring is activated and/or

deactivated by sensor:

- If sens_ID ≠ 0 and Isflag = 0, the spring element is activated by the sens_ID.

- If sens_ID ≠ 0 and Isflag = 1, the spring element is deactivated by the sens_ID.

- If sens_ID

0 and Isflag = 2, then:

- The spring is activated and/or, deactivated by sens_ID. (if sensor is ON, spring is ON; if sensor is OFF, spring is OFF).

- The spring reference length ( ) is the distance between spring node N1 and N2 at the time of the sensor's activation.

- If a sensor is used for activating or deactivating a spring, the reference length of the spring at sensor activation (or deactivation) is equal to the nodal distance at time =0; except if sensor flag is equal to 2.

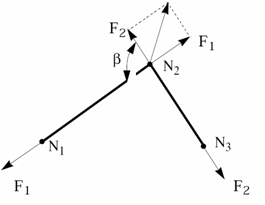

- Friction models definition:

Figure 3.- If fct_IDfr and Fric = 0 (no friction), then .

- If fct_IDfr = 0 and Fric > 0, then constant Coulomb friction coefficient used:

- If fct_IDfr > 0, then variable

friction is calculated as a function on relative force between two pulley

branches:

Ifr = 0 (symmetrical behavior),

Ifr = 1 (non-symmetrical behavior),

Friction force is computed as:(4) Where,(5) - Angle (radians unit)

- Function of fct_IDfr

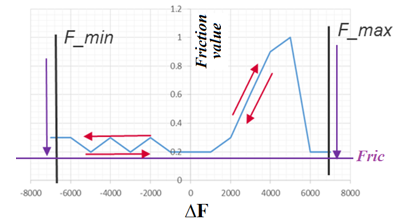

- If Ifr = 1 (non-symmetrical

behavior) and when F_min (or F_max) is reached,

friction is switching permanently from the function definition to the constant value

Fric.

Figure 4.Otherwise, the friction value is defined according to the input function fct_IDfr.