Rear SLA (2pc LCA)

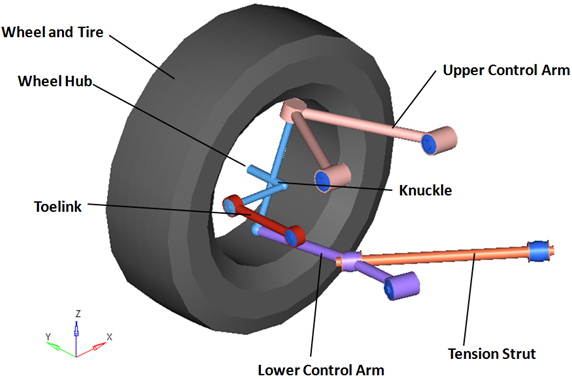

A Short-Long Arm or SLA suspension is included in the vehicle library as both a front and rear suspension. This configuration is also known as a Double Wishbone suspension. This variant of the suspension uses a two-piece lower control arm. The SLA name is derived from the length of the control arms. The lower arm is typically long to provide a good spring lever ratio. The upper arm is typically short to provide the proper camber curve. This suspension is widely used on cars, light trucks, and on independent suspension heavy trucks.

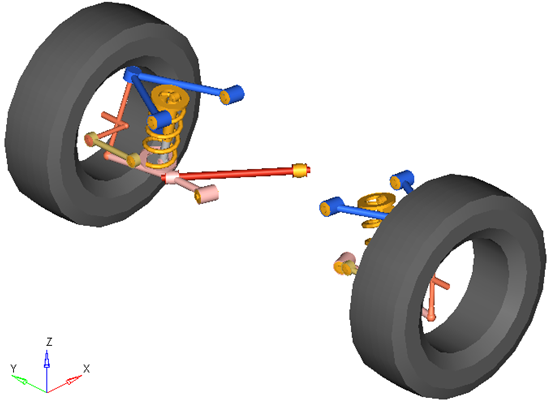

Figure 1. Rear SLA Suspension with Two (2) Piece Lower Control Arm and Optional Coil Spring, Shock Absorber, and External Jounce Bumper Subsystems

Model Use

- The wheel body represents the mass of the tire and the rim.

- The wheel hub body represents the mass and inertia of other rotating bodies such as a brake rotor, but not the half-shafts if the suspension is driven. The wheel hub and brake rotor have no associated graphics.

- The wheel and wheel hub parts use the Wheel CG location as the center of gravity.

- The upper control arm bushings are defined so their axes point at each other (like hinges on a door). If the rear bushing is moved, both bushings realign so that they have the same axis of rotation. The lower control arm bushings’ rotational axes are defined in the same manner.

- When the suspension is built as a kinematic suspension (using the option menu in the System/Assembly panel), the upper control arm bushings are replaced with a single revolute joint located at the forward bushing location, with a rotational axis directed along the line from the forward bushing to the rearward bushing. The lower control arm bushings are replaced with a revolute joint in the same fashion.

- Each body’s Center of Gravity (CG) is estimated from the body’s geometry. The formulas are coded into the point panel and can be seen via the graphical user interface. If more accurate CG locations are available they should be used.

- A wide variety of combinations of suspensions and subsystems can be built using the

Assembly Wizard. You are encouraged to build systems and

understand the resulting model using the graphical user interface.

When building a new suspension model, build the model with all of the optional systems (stabilizer bar, etc) included in the model. Immediately turn off the systems using the Project Browser and run an analysis on the base suspension to ensure it solves properly. As data becomes available for the optional systems; activate those systems and populate them with data.

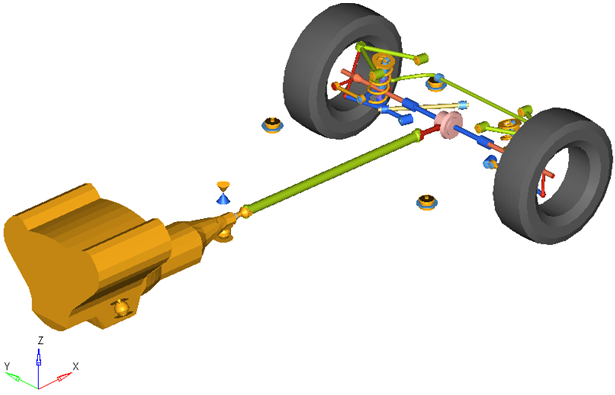

Figure 2. Rear-Half-Vehicle Model Employing a SLA Suspension with Two (2) Piece Lower Control Arm

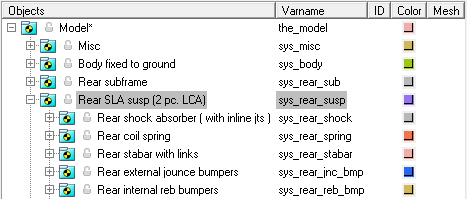

Figure 3. Browser View of a Rear-Half-Vehicle Model Systems and Subsystems Employing a SLA Suspension with Two (2) Piece Lower Control Arm

Attachments

| Entity | Attaches To |

|---|---|

| Lower Control Arm | Default: Sub-frame No subframe: Vehicle body No vehicle body: Ground |

| Upper Control Arm | Default: Vehicle body No vehicle body: Ground |

| Toe Link | Default: Sub-frame No subframe: Vehicle body No vehicle body: Ground |

| Tension Strut | Default: Sub-frame No subframe: Vehicle body No vehicle body: Ground |

Points

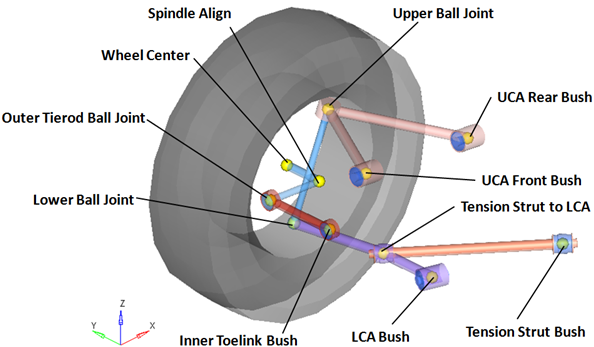

Figure 4. Right Side Principal Points – Rear SLA Suspension with a Two (2) Piece Lower Control Arm

Bodies

Figure 5. Right Side Bodies – Rear SLA Suspension with Two (2) Piece Lower Control Arm

- The wheel hub body has no associated graphics and therefore is not visible in the image above.

- Only right side bodies are shown (as the left side bodies are symmetrical), and the coil spring has been omitted from the image above for clarity.

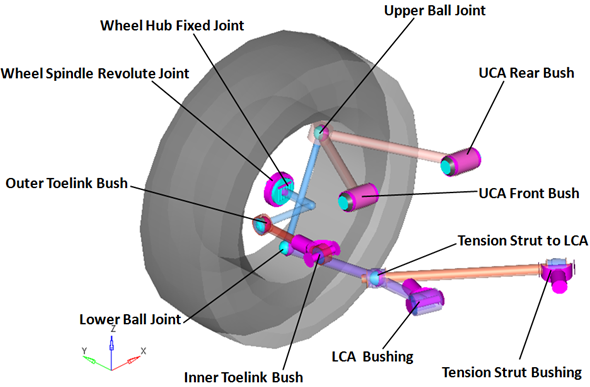

Bushings and Joints

| Label | Type | Body 1 | Body 2 | Point | Notes |

|---|---|---|---|---|---|

| Lower Ball Joint | Spherical | Knuckle | Lower Control Arm | Lower Ball Joint | |

| Upper Ball Joint | Spherical | Knuckle | Upper Control Arm | Upper Ball Joint | |

| Wheel Spindle | Revolute | Wheel Hub | Knuckle | Wheel Center | |

| Wheel Hub Fix Jt |

Fixed-Joint | Wheel | Wheel Hub | Wheel Center | When Spindle compliance is set to Yes, the joint type changes to universal and a bushing is superimposed to model the wheel bearing compliance. |

| Tension Strut Bushing | Universal | Tension Strut | Subframe, Vehicle Body, or Ground | Tension Strut Bush | When the Compliant option is set to No, this joint compliance is turned "Off" and behaves as a pure universal joint. |

| LCA Bushing | Bushing | Lower Control Arm | Subframe, Vehicle Body or Ground | LCA Rear Bush | When the Compliant option is set to No, this joint compliance is turned "Off" and behaves as a pure universal joint. |

| UCA Front Bush | Bushing | Upper Control Arm | Subframe, Vehicle Body or Ground | UCA Front Bush | When the Compliant option is set to No, this bushing becomes a revolute joint. |

| UCA Rear Bush | Bushing | Upper Control Arm | Subframe, Vehicle Body or Ground | UCA Rear Bush | When the Compliant option is set to No, this bushing is deactivated. |

| Inner Toe Link Bush | Universal Joint | Toe Link | Subframe, Vehicle Body or Ground | Inner Toe Link Bush | When the Compliant option is set to No, this joint compliance is turned "Off" and behaves as a pure universal joint. |

| Outer Toe Link Bush | Spherical Joint | Toe Link | Knuckle | Outer Toe Link Bush | When the Compliant option is set to No, the compliance for this joint is turned "Off" and behaves as a pure spherical joint. |

Figure 6. Right Side Joints and Bushings: Rear SLA Suspension with Two (2) Piece Lower Control Arm

Similar Suspensions

Front SLA (1pc LCA)

Front SLA (2pc LCA)

Rear SLA (1pc LCA)