/PROP/TYPE22 (TSH_COMP)

Block Format Keyword This property set is used to define the composite thick shell property set.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /PROP/TYPE22/prop_ID/unit_ID or /PROP/TSH_COMP/prop_ID/unit_ID | |||||||||

| prop_title | |||||||||

| Isolid | Ismstr | Icstr | Inpts | Iint | dn | ||||

| qa | qb | ||||||||

| VX | VY | VZ | skew_ID | Iorth | Ipos | ||||

| Ashear | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| ti/t | Zi | mat_IDi | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| prop_ID | Property

identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| prop_title | Property

title. (Character, maximum 100 characters) |

|

| Isolid | Solid elements formulation flag.

(Integer) |

|

| Ismstr | Small strain formulation

flag. 4

(Integer) |

|

| Icstr | Constant stress

formulation flag. Only valid for Isolid =

14.

(Integer) |

|

| Inpts | Number of integration

points. 2

(Integer) Where,

|

|

| Iint | Number of layers when 9

< number of layers ≤ 200. Only valid for Isolid =

14. 4 (Integer) |

|

| dn | Numerical damping for

stabilization. Only valid for Isolid =

15. Default = 0.1 (Real) |

|

| qa | Quadratic bulk

viscosity. Default = 1.10 (Real) Default = 0.0 for /MAT/LAW70 |

|

| qb | Linear bulk

viscosity. Default = 0.05 (Real) Default = 0.0 for /MAT/LAW70 |

|

| Ashear | Shear factor. Default = 1.0 (Real) |

|

| VX | X component for reference

vector. Default = 1.0 (Real) |

|

| VY | Y component for reference

vector. Default = 0.0 (Real) |

|

| VZ | Z component for reference

vector. Default = 0.0 (Real) |

|

| skew_ID | Skew identifier. If the local skew has been defined, its X-axis replaces the reference vector (VX, VY, and VZ will be ignored). (Integer) |

|

| Iorth | Orthotropic system

formulation flag for reference vector.

(Integer) |

|

| Ipos | Layer positioning flag for

reference vector.

(Integer) |

|

| Minimum time

step. Default = 106 (Real) |

||

| Angle for layer

I. (Real) |

||

| ti/t | Relative thickness of

layer i.

(Real) |

|

| Zi | Z position (normalized by

the thickness) of layer i (-0.5 ≤

Zi ≤

0.5). Default = 0.0 (Real) |

|

| mat_IDi | Material identifier for

layer I. (Integer) |

Example

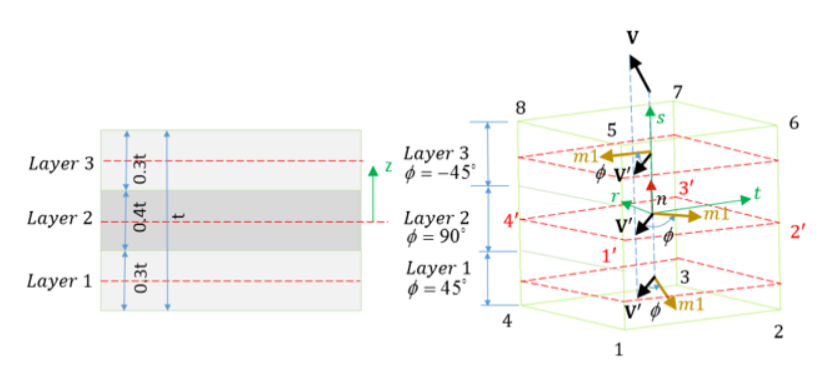

Figure 1.

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 1. LOCAL_UNIT_SYSTEM:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/2

unit for prop

# MUNIT LUNIT TUNIT

kg mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. GEOMETRICAL SETS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/PROP/TYPE22/1/2

TSH_COMP example

# Isolid Ismstr Icstr Inpts Iint dn

14 0 010 333 0 0

# q_a q_b

0 0

# Vx Vy Vz skew_ID Iorth Ipos

1 -1 1 0 0 0

# Ashear

0

# PHI_I T_I/T ZI MAT_I

45 0.3 0 1

90 0.4 0 2

-45 0.3 0 1

# dt_min

0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#enddata

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- Isolid - Solid formulation

- Isolid =14 formulation (H8 element) must use constant stress formulation (Icstr > 0), which refers to local isoparametric orthogonolized system r-s-t. Definition of the system is described in the comments of /PROP/TYPE6 (SOL_ORTH).

- When using Isolid=15 with pentahedron elements, /PENTA6 elements are recommended but degenerated /BRICK elements can also be used.

- Number of layers.

- For Isolid =

14 formulation (HA8 element), number of layers (

< 9 ) is defined as:

- If Icstr = 001, the number of layers in t direction is equal to k value from Inpts field.

- If Icstr = 010, the number of layers in s direction is equal to j value from Inpts field (Icstr = 010; Inpts = 282; for a number of 8 layers in s direction).

- If Icstr = 100, the number of layers in r direction is equal to i value from Inpts field.

- For Isolid formulation

(HA8 element) when the number of layers > 9 is defined as:

- Use Iint for Isolid

formulation (HA8 element) when the number of layers > 9.

In this case, the thickness direction integration points defined by Inpts should be zero.

Example, Icstr = 010; Inpts = 202; Iint = 100 for a number of 100 layers in "s" direction.

- Use Iint for Isolid

formulation (HA8 element) when the number of layers > 9.

- For Isolid =

14 formulation (HA8 element), number of layers (

< 9 ) is defined as:

- When using the automatic setting option Ismstr = Icpre = Iframe=-1, the values for these options are defined using the best options based on the element formulation, element type, and material. Alternatively, defining Ismstr = Icpre = Iframe=-2 will overwrite the values for these options defined in this property with the best value based on element type and material law. To see the values defined by Radioss, review the “PART ELEMENT/MATERIAL PARAMETER REVIEW” section of the Starter output file.

- Ismstr - Small strain

formulation flag.

- Starting with version 2017, Lagrangian elements whose volume becomes

negative during a simulation will automatically switch strain

formulations to allow the simulation to continue. When this occurs, a

WARNING message will be printed in the Engine output file. The following

options are supported.

Element Type Element Formulation Strain Formulation Negative Volume Handling Method /BRICK Isolid =14, 15 Full geometric nonlinearities Ismstr = 2, 4

Switch to small strain using element shape from cycle before negative volume.

- Starting with version 2017, Lagrangian elements whose volume becomes

negative during a simulation will automatically switch strain

formulations to allow the simulation to continue. When this occurs, a

WARNING message will be printed in the Engine output file. The following

options are supported.

- Othotropy in local

coordinate system.

- The thick shell orthotropy is planar and the third orthotropy direction is coincident with the normal to the shell plane.

- Global vector or skew_ID is used to define the othotropy direction. The global vector or the -axis of specified skew (in this case, global vector is ignored) is projected to the mean plane of soslid element.

- For Isolid=14, the mean plane of the element depends on Icstr.

- r-s for Icstr=001

- r-t for Icstr=010

- s-t for Icstr=001.

- is the angle (in degrees) between the first direction of orthotropy and projection of reference vector on the shell mean plane for layer i.

- Material used for

layer

- Material law type used in Mat_IDi can be different for each layer.

- For Isolid= 15, the material law number defined in /PART will be used to compute the contact interface stiffness and the hourglass stresses.