Forces Panel

Use the Forces panel to create concentrated forces. This is accomplished by applying a load, representing forces, to a node, point, set, or component.

Location: Analysis page

Forces are load config 1 and are displayed as a vector with the letter F at the tail end.

Create Subpanel

If you do not specify a vector using the plane and vector collector, the force will be normal to the selected nodes' adjacent surfaces by default.

Loads from files formatted as CSV (Comma Separated Values) or SSV (Space-Separated Values) text files can be interpolated.

| Option | Action |

|---|---|

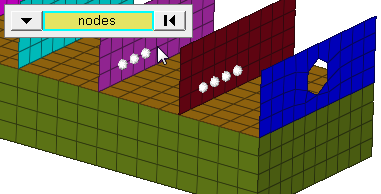

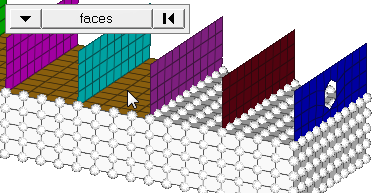

| entity selector | Choose the entities to

which the force will be applied. In any case, the forces are applied to nodes; this selection simply determines how those nodes are selected. Geometric points select the nodes at which they exist. Comps select all of the nodes contained within the chosen component. If you choose comps or sets, HyperLife Weld Certification draws the forces using a single indicator. As a result, a new button called display appears. This allows you to indicate where in the model you wish the indicator to be drawn, and requires additional steps. When nodes is selected, use the switch to

change the selection mode.

|

| global system / local system |

|

| magnitude / vector selector | Specify the magnitude

and direction of the force.

|

| relative size/ uniform size |

By default, loads are displayed relative to the model

size.

|

| label load | Display the load's text labels in modeling window. |

| load types | Select a load type. |

| face angle/individual selection |

|

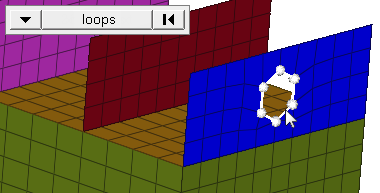

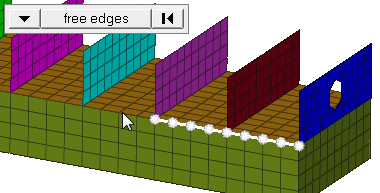

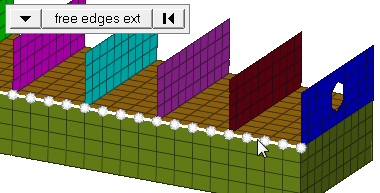

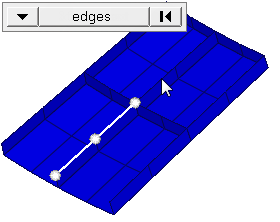

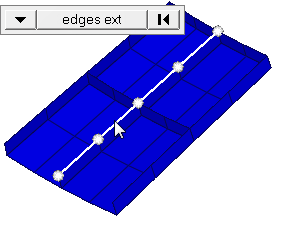

| edge angle |

Split edges that belong to a given face. When the edge

angle is 180 degrees, edges are the continuous boundaries of faces. For smaller

values, these same boundary edges are split wherever the angle between segments

exceeds the specified value. A segment is the edge of a single element.

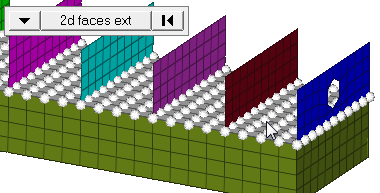

Important: Only available when the entity selector is set to nodes and the

selection mode is set to free edges, free edges ext, edges, or edges

ext.

|

Update Subpanel

| Option | Action |

|---|---|

| entity selector | Choose the entities to

which the force will be applied. In any case, the forces are applied to nodes; this selection simply determines how those nodes are selected. Geometric points select the nodes at which they exist. Comps select all of the nodes contained within the chosen component. If you choose comps or sets, HyperLife Weld Certification draws the forces using a single indicator. As a result, a new button called display appears. This allows you to indicate where in the model you wish the indicator to be drawn, and requires additional steps. When nodes is selected, use the switch to change the selection mode. |

| global system / local system |

|

| magnitude / vector selector | Specify the magnitude

and direction of the force.

|

| relative size / uniform size |

By default, loads are displayed relative to the model

size.

|

| label load | Display the load's text labels in modeling window. |

| load types | Select a load type. |

Command Buttons

| Button | Action |

|---|---|

| create | Create the load. |

| create/edit | Create the load and opens the card image for editing. |

| reject | Revert the most recent changes. |

| review | Review the load in the graphic area. |

| update | Update the load with the most recent changes. |

| return | Exit the panel. |

Equations allow you to create force, moment, pressure, temperature or flux loads on your model where the magnitude of the load is a function of the coordinates of the entity to which it is applied. An example of such a load might be an applied temperature whose intensity dissipates as a function of distance from the application point, or a pressure on a container walls due to the level of a fluid inside.

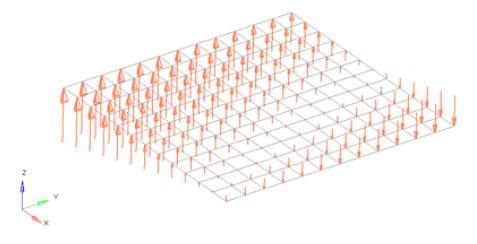

Figure 11. Flat Plate with a Linear Function for an Applied Force Magnitude = 20 – (5*x+2*y). The flat plate is 20 x 20 units, lying in the X-Y plane with the origin at the center.

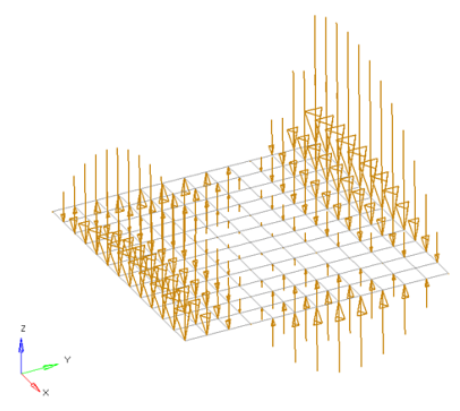

Figure 12. Flat Plate with a Polynomial Function with Magnitude = x^2-2y^2+x*y+x+y. The flat plate is 20 x 20 units, lying in the X-Y plane with the origin at the center.

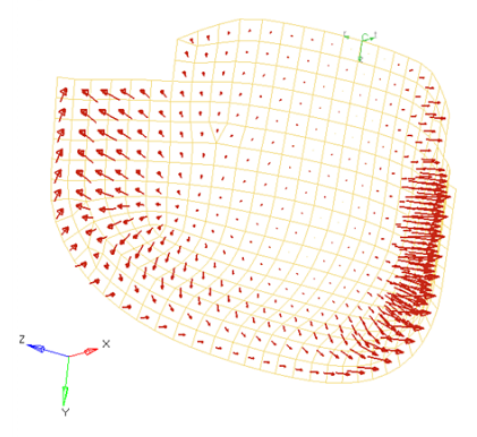

Figure 13. Curved Surface with a Polynomial Function for an Applied Pressure Magnitude = -((x^2+2*y^2+z)/1000). The pressure function is defined in terms of the cylindrical coordinate system displayed at the top edge of the elements.