Gas Generator

The gas generator model should represent all details available in CAD data: gas generator, injector openings, and retainers.

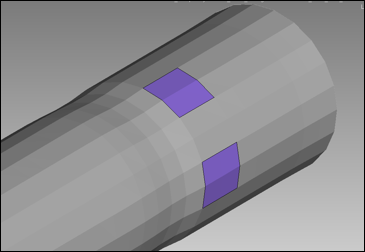

Figure 1. Inflator and Injector Elements

The injection direction is opposite to element's normal. Elements from different injectors should not share common elements. Radioss will assume that the element belongs to the last defined injector. Elements from a vent hole or porous surface also should not share common elements with injectors. Radioss automatically excludes the elements from vent or porous surface definition.

The injector surface can also be defined on an internal surface insideof airbag volume. In this case the gas flow direction is opposite to the internal surface element's normal.

The inflator property /PROP/INJECT1 and /PROP/INJECT2 define the parameters of the injected gas composition. Each of the gas components should be specified as a separate material card: /MAT/GAS/MASS, /MAT/GAS/MOLE, or /MAT/GAS/PREDEF. In the latter case, the gas material is built according to the keyword given in the /MAT/GAS/PREDEF card and units specified in the /BEGIN card.

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/GAS/MASS/1

INJECTOR MIXTURE

# MW

.03300

# Cpa Cpb Cpc Cpd Cpe

1070.00 0 0 0 0

# Cpf

0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|The molecular weight and coefficients of specific heat coefficient are defined for each of injected gas components.

should be monotonically increasing for temperatures between ambient temperature and the maximum temperature value given in the temperature curves of the injector. When the function is not monotonically increasing, Radioss automatically corrects the function to keep it monotonic. This can happen when > 0 or one of , , , coefficients are negative.

The composition of the injected gas, injection mass flow and temperature for each of the gas components are defined in the /PROP/INJECT1 or /PROP/INJECT2 cards.

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/PROP/INJECT1/1

Inflator 1

# Ngases Iflow Ascale_T

5 1 1

# mat_ID fct_IDM fct_IDT Fscale_M Fscale_T

1 2 1 0 0

# mat_ID fct_IDM fct_IDT Fscale_M Fscale_T

2 3 1 0 0

# mat_ID fct_IDM fct_IDT Fscale_M Fscale_T

3 4 1 0 0

# mat_ID fct_IDM fct_IDT Fscale_M Fscale_T

4 5 1 0 0

# mat_ID fct_IDM fct_IDT Fscale_M Fscale_T

5 6 1 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

This card is then referenced in /MONVOL/FVMBAG1 airbag card.

The injector Time to Fire (TTF) should be determined through a sensor in /MONVOL/FVMBAG1, not through a shift of the mass and temperature curves.

ELEM: 92 <-> SH3N : 55261587 - INFLATOR : 1

ELEM: 502 <-> SH3N : 55262048 - INFLATOR : 1

ELEM: 622 <-> SH3N : 55261581 - INFLATOR : 1

ELEM: 627 <-> SH3N : 55261568 - INFLATOR : 1

ELEM: 633 <-> SH3N : 55262068 - INFLATOR : 1

ELEM: 814 <-> SH3N : 55261601 - INFLATOR : 1

The inflator model should be validated using a tank test simulation. The tank test report should include the pressure and temperature measured in the test, injector mass flow for each of the gas components, and temperature curves. The pressure and temperature from the test could be compared to the average pressure and temperature in the simulation.