Airbag Fabric Material

The nonlinear anisotropic material LAW58 used be used as the airbag material.

The material should be tested and validated using the following tests: picture frame test, biaxial tension test, and uniaxial tension test in the weft and wrap directions.

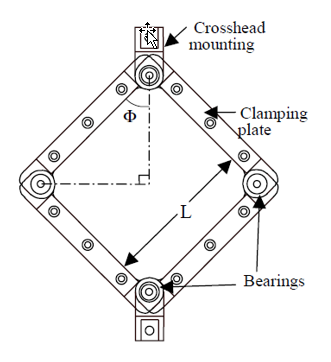

Figure 1. Picture Frame Shear Rig

- and

- Vertical displacement of the upper corner of the specimen

- Side length of the specimen

- Measured force

- Fabric thickness

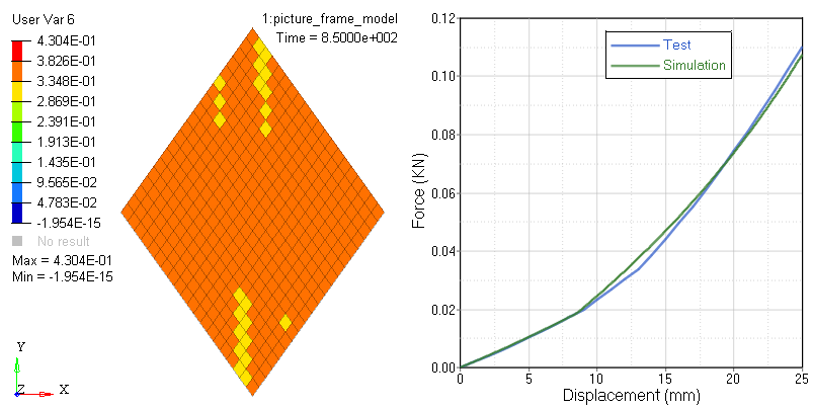

Figure 2. Picture Frame Simulation and Shear Stress as Function of Anisotropy Angle

Cyclic loading and unloading picture frame tests can be performed to extract the loading and unloading curves in shear. The curves can be directly used as input in LAW58 material. The curves should be specified both for the negative and positive values of anisotropic angle in degrees.

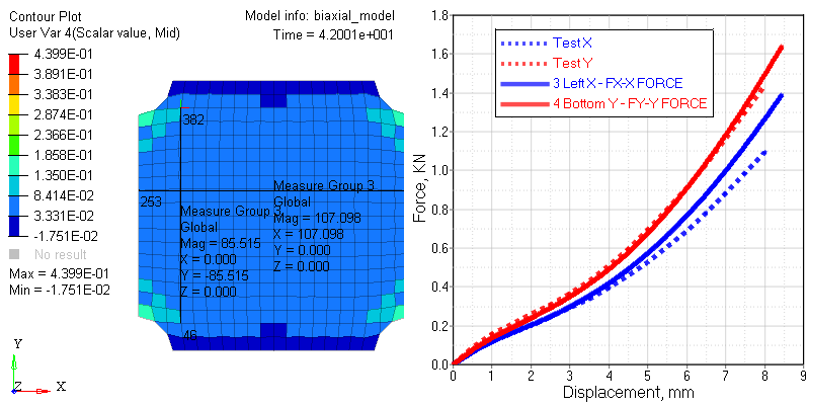

Figure 3. Biaxial Simulation and Forces Displacement Curves in Warp and Weft

Directions

Figure 3. Biaxial Simulation and Forces Displacement Curves in Warp and Weft

DirectionsThe force displacement curves for warp and weft direction can be recalculated into stress and strain curves using size and thickness of the specimen. Due to corner boundary effects, slight scaling or other tuning of the input curves may be necessary.

Before the woven warp and weft fibers become straight, uniaxial test data can be used to validate the initial fabric stiffness for LAW58. During this phase, the fabric is normally softer. The strain straightening parameters S1 and S2 define when the strain at when the fibers are straight. Flex1 and Flex2 are the scaling coefficients which reduce the stiffness of the warp and weft curves while the fibers are not straight. In many cases the phase is very short and it can be ignored by defining S1=S2=1e-03.

The Flex1 and Flex2 parameters are also used to scale down fabric stiffness in warp and weft direction in compression. By default, Flex1=Flex2=Flex=0.01.

Uniaxial test data for 0, 90 and 45 degree fiber orientations can be used to double check the airbag fabric LAW58 material data that was validated using the picture frame test and biaxial test.

Airbag tethers are normally loaded in uniaxial tension. Uniaxial tension tests should be completed and validated for these materials. Validation of the 45 degree oriented specimens is also important for these materials.

LAW58 materials can include the hysteresis effect in cyclic loading. The stress strain curves for loading and unloading should be extracted from the cyclic biaxial tension test.

Generic LAW58 materials in kg, mm, ms with loading and unloading option with loading and unloading option.

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW58/2

Altair test fabric law58

# RHO_I RHO_O

8E-7 0

# E1 B1 E2 B2 FLEX

0.380 0 0.380 0 1.0

# G0 GT AlphaT0 Gsh sens_ID

0.0035 0.0055 7.175 1

# Df Ds Gfrot ZEROSTRESS

0 0 0 1

# N1 N2 S1 S2

1 1 0 0

# Dir 1

500 1.00

# Dir 2

501 1.00

# Dir12

502 1.00

# FCT_ID4 FCT_ID5 Fscale4 Fscale5 FCT_ID6 Fscale6

600 600 1 1 502 1

/FUNCT/500

stress-strain curve dir 1

# X Y

0.0000000000e+000 0

1.0000000000e-002 2.9343543750e-003

2.0000000000e-002 5.2630337500e-003

3.0000000000e-002 6.9235412500e-003

4.0000000000e-002 8.4176677083e-003

5.0000000000e-002 1.0120216458e-002

6.0000000000e-002 1.2102790000e-002

7.0000000000e-002 1.4219608542e-002

8.0000000000e-002 1.6595997708e-002

9.0000000000e-002 1.9202795833e-002

1.0000000000e-001 2.2040856250e-002

1.1000000000e-001 2.5270391667e-002

1.2000000000e-001 2.8711702083e-002

1.3000000000e-001 3.2558656250e-002

1.4000000000e-001 3.6676625000e-002

1.5000000000e-001 4.1031145833e-002

1.6000000000e-001 4.5697987500e-002

/FUNCT/600

unloading stress-strain curve dir 1, 2

# X Y

0.0000000000e+000 0.0000000000e+000

2.0000000000e-002 5.0000000000e-004

4.0000000000e-002 1.0000000000e-003

6.0000000000e-002 2.0000000000e-003

8.0000000000e-002 5.0000000000e-003

1.0000000000e-001 1.0000000000e-002

1.2000000000e-001 3.0000000000e-002

1.4000000000e-001 7.0000000000e-002

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/501

stress-strain curve dir 2

# X Y

0.0000000000e+000 0

1.0000000000e-002 3.7475658333e-003

2.0000000000e-002 6.4746864583e-003

3.0000000000e-002 8.6433156250e-003

4.0000000000e-002 1.0769805833e-002

5.0000000000e-002 1.2923027083e-002

6.0000000000e-002 1.5325416250e-002

7.0000000000e-002 1.8090380208e-002

8.0000000000e-002 2.1231860417e-002

9.0000000000e-002 2.4870956250e-002

1.0000000000e-001 2.8884937500e-002

1.1000000000e-001 3.3246235417e-002

1.2000000000e-001 3.8027027083e-002

1.3000000000e-001 4.3127925000e-002

1.4000000000e-001 4.8519200000e-002

1.5000000000e-001 5.4217816667e-002

1.6000000000e-001 6.0077625000e-002

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/502

stress-strain curve dir 12

# X Y

-1.8803485061e+001 -1.5770466522e-003

-1.8097254117e+001 -1.5114614261e-003

-1.7387852291e+001 -1.4413505922e-003

-1.6675208927e+001 -1.3674267252e-003

-1.5959251230e+001 -1.2915012899e-003

-1.5239904181e+001 -1.2138769816e-003

-1.4517090425e+001 -1.1332172636e-003

-1.3790730171e+001 -1.0497187778e-003

-1.3060741077e+001 -9.6747019039e-004

-1.2327038129e+001 -8.8635494868e-004

-1.1589533515e+001 -8.0307143684e-004

-1.0848136486e+001 -7.1778894110e-004

-1.0102753220e+001 -6.4282044814e-004

-9.3532866620e+000 -5.8468504129e-004

-8.5996363643e+000 -5.2563223081e-004

-7.8416983143e+000 -4.6541585980e-004

-7.0793647491e+000 -4.0614312591e-004

-6.3125239587e+000 -3.6168074948e-004

-5.5410600764e+000 -3.1690734331e-004

-4.7648528535e+000 -2.7145205177e-004

-3.9837774194e+000 -2.2537031107e-004

-3.1977040240e+000 -1.8050370403e-004

-2.4064977614e+000 -1.3620800862e-004

-1.6100182740e+000 -9.1442121733e-005

-8.0811943303e-001 -4.6243379765e-005

0 0

8.0811943303e-001 4.6243379765e-005

1.6100182740e+000 9.1442121733e-005

2.4064977614e+000 1.3620800862e-004

3.1977040240e+000 1.8050370403e-004

3.9837774194e+000 2.2537031107e-004

4.7648528535e+000 2.7145205177e-004

5.5410600764e+000 3.1690734331e-004

6.3125239587e+000 3.6168074948e-004

7.0793647491e+000 4.0614312591e-004

7.8416983143e+000 4.6541585980e-004

8.5996363643e+000 5.2563223081e-004

9.3532866620e+000 5.8468504129e-004

1.0102753220e+001 6.4282044814e-004

1.0848136486e+001 7.1778894110e-004

1.1589533515e+001 8.0307143684e-004

1.2327038129e+001 8.8635494868e-004

1.3060741077e+001 9.6747019039e-004

1.3790730171e+001 1.0497187778e-003

1.4517090425e+001 1.1332172636e-003

1.5239904181e+001 1.2138769816e-003

1.5959251230e+001 1.2915012899e-003

1.6675208927e+001 1.3674267252e-003

1.7387852291e+001 1.4413505922e-003

1.8097254117e+001 1.5114614261e-003

1.8803485061e+001 1.5770466522e-003

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|The input curves in LAW58 should increase monotonically. Stress strain curves in warp and weft direction should have exactly 2 intersection points: at strain 0 and some positive strain. Shear stress vs anisotropic angle curve should have 3 intersection points: at angle 0, one positive and one negative angle. All loading and unloading curves should be specified.

The material parameter ZEROSTRESS=1 should be set and a sensor should be used in the material LAW58 definition for the activation of airbag reference geometry. This should be the same sensor which is used to start the first injection in /MONVOL/FVMBAG1.

Property Cards for Airbag Fabric

Property /PROP/TYPE16 (SH_FABR) should be used with LAW58.

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/PROP/TYPE16/1

Shell

# Ishell Ismstr Ish3n

4 4 2

# hm hf hr dm dn

0 0 0 0 0

# N Istrain Thick Ashear Ithick Iplas

1 0 0.3 0 0 0

# Vx Vy Vz Isk Ipos

1 0 0 0 0

# Phi Alpha Thick Z Mat

0 0 0.3 0 1

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|For fabric there is no bending stiffness. Therefore the membrane formulation N=1 should be used for the airbag fabrics property. The airbags should be meshed with tria elements with these property options: Ishell=4 , Ismstr=4, and Ish3n=2.

In the /PROP/TYPE16 (SH_FABR) property, the fabric material is defined for each layer. This should be exactly the same material used in the /PART card definition.