Airbag Fabric Porosity

Porosity of airbag material is modeled by the addition of a porosity card /LEAK/MAT to /MAT/LAW58 card.

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW58/1

Altair test fabric law58

# Init. dens. Ref. dens.

8E-7 0

# E1 B1 E2 B2 FLEX

0.380 0 0.380 0 1.0

# G0 GT AlphaT Sensor

0.0035 0.0055 7.175 1

# Df Ds Gfrot ZeroStress

0 0 0 1

# N1 N2 S1 S2

1 1 0 0

# Dir 1

500 1.00

# Dir 2

501 1.00

# Dir12

502 1.00

# FCT_ID4 FCT_ID5 Fscale4 Fscale5 FCT_ID6 Fscale6

600 600 1 1 502 1

/LEAK/MAT/1

Fabric

# Ileak AscaleT AscaleP

1

# AC' fct_IDAC’

# LC AC

1.0e-03 1.0e-03

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|The /LEAK/MAT specifies how the effective porous area of a component having this material will vary as a function time or pressure. It is determined by the value of Ileakage.

Where, and are the stretches in warp and weft directions and is the angle between warp and weft directions.

with and .

Parts with this material are considered porous, when referenced via a surface ID using the /MONVOL/FVMBAG1 surf_IDps option.

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MONVOL/FVMBAG1/1

DAB

# Isur

4

# Scal_T Scal_P Scal_S Scal_A Scal_D

0 0 0 0 0

# Mat_ID Mu Pext Tphi Iequi Ittf

4 0.1 0.00010135 0 0 3

# Njet

1

# Inj_ID Isensor surf_IDinj

10 1 100

# Nvent Nps

0 1

#Sur_id_ps Iform_ps

4 1

# Tstart Tstop dPdef DtPdef ldtpdef

….

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|- Iformps = 1 (Isentropic - Wang Nefske)

- Iformps = 2

Where, v is the outflow gas velocity (Chemkin)

- Iformps = 3 (Graefe)

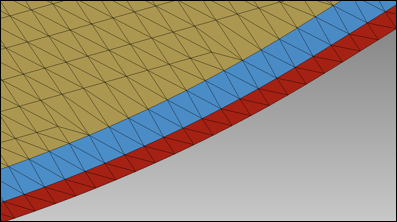

Figure 1. Porous Fabric (Yellow) is Separated from Permeable Seam (Red) by Blue Non-Vent Component