/MAT/PLAS_ZERIL

Block Format Keyword This law defines an isotropic elasto-plastic material using the Zerilli-Armstrong plasticity model.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/PLAS_ZERIL/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | v | ||||||||

| C0 | C5 | n | |||||||

| C1 | ICC | Fsmooth | Fcut | ||||||

| C3 | C4 | Tr | |||||||

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material

identifier (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier (Integer, maximum 10 digits) |

|

| mat_title | Material

title (Character, maximum 100 characters) |

|

| Initial

density (Real) |

||

| E | Young's

modulus (Real) |

|

| v | Poisson's

ratio (Real) |

|

| C0 | Plasticity yield

stress (Real) |

|

| C5 | Plasticity hardening

parameter (Real) |

|

| n | Plasticity hardening

exponent. 5 Default = 1.0 (Real) |

|

| Failure plastic

strain. Default = 1030 (Real) |

||

| Plasticity maximum

stress. Default = 1030 (Real) |

||

| C1 | Strain rate formulation

coefficient. (Real) |

|

| Reference strain rate

(must be 1 s-1 converted into user's

units). (Real) |

||

| ICC | Strain rate computation

flag. 7

(Integer) |

|

| Fsmooth | Smooth strain rate option flag.

(Integer) |

|

| Fcut | Cutoff frequency for

strain rate filtering. 8 Default = 1030 (Real) |

|

| C3 | Temperature effect

coefficient. (Real) |

|

| C4 | Temperature effect coefficient.

(Real) |

|

Specific heat per unit of volume.

(Real) |

||

| Tr | Reference

temperature. Default = 298 K (Real) |

Comments

- The Zerilli-Armstrong law is applicable only to shells and solids.

- The equation that describes

stress during plastic deformation is:

(1) Where,- Plastic strain

- Strain rate

- Temperature

- Yield stress should be strictly positive.

- When

reaches

in one integration point, then based on the element

type:

- Shell elements:

The corresponding shell element is deleted.

- Solid elements:

The deviatoric stress of the corresponding integral point is permanently set to 0; however, the solid element is not deleted.

- Shell elements:

- n must be less than 1.

- If is 0, there is no strain rate effect.

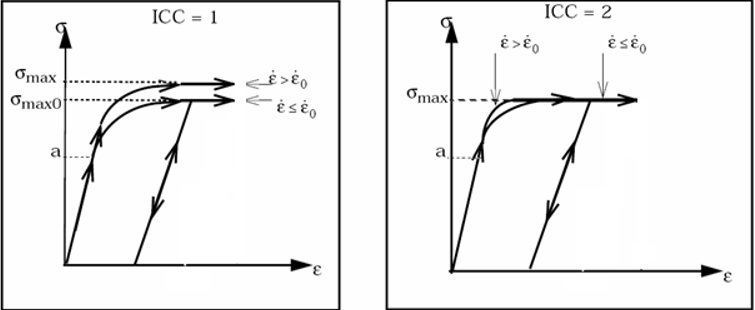

- ICC is a flag of the strain rate

effect on material maximum stress

:

Figure 1. - Strain rate filtering input (Fcut) is only available for shell and solid elements.

- The strain rate filtering is used to smooth strain rates.

- Temperature is computed

assuming adiabatic conditions:

(2) Where, Eint is the internal energy computed by Radioss.

- When the temperature is not initialized using /HEAT/MAT or /INITEMP, the reference temperature (Tr) is also the initial temperature.