/MAT/LAW60 (PLAS_T3)

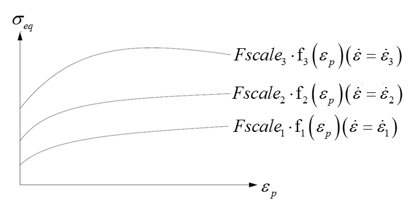

Block Format Keyword This law models an isotropic elasto-plastic material using user-defined functions for the work-hardening portion of the stress-strain curve (that is, plastic strain versus stress) for different strain rates.

It is similar to LAW36, except yield stress is a nonlinear interpolation from the functions.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW60/mat_ID/unit_ID or /MAT/PLAS_T3/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | |||||||||

| Nfunct | Fsmooth | Chard | Fcut | ||||||

| fct_IDp | Fscale | fct_IDE | Einf | CE | |||||

| fct_ID1 | fct_ID2 | fct_ID3 | fct_ID4 | fct_ID5 | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fct_ID6 | fct_ID7 | fct_ID8 | fct_ID9 | fct_ID10 |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Fscale1 | Fscale2 | Fscale3 | Fscale4 | Fscale5 | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Fscale6 | Fscale7 | Fscale8 | Fscale9 | Fscale10 | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material

identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material

title. (Character, maximum 100 characters) |

|

| Initial

density. (Real) |

||

| E | Young's

modulus. (Real) |

|

| Poisson's

ratio. (Real) |

||

| Failure plastic

strain. Default = 1.0 × 1030 (Real) |

||

| Tensile failure strain at

which stress starts to reduce. Default = 1.0 x 1030 (Real) |

||

| Maximum tensile failure

strain at which the element is deleted. Default = 2.0 x 1030 (Real) |

||

| Nfunct | Number of functions. It

should be 4 <

Nfunct <

10. Default ≤ 10 (Integer) |

|

| Fsmooth | Smooth strain rate option flag.

(Integer) |

|

| Chard | Hardening coefficient.

(Real) |

|

| Fcut | Cutoff frequency for

strain rate filtering. 7 Default = 1.0 × 1030 (Real) |

|

| fct_IDp | Pressure versus yield

factor function. 9 Default = 0 (Integer) |

|

| Fscale | Scale factor for yield

factor in fct_IDp. Default = 1.0 (Real) |

|

| fct_IDE | Function identifier for

the scale factor of Young's modulus, when Young's modulus is

function of the plastic strain. 6 Default = 0: in this case the evolution of Young's modulus depends on Einf. and CE. (Integer) |

|

| Einf | Saturated Young's modulus

for infinitive plastic strain. (Real) |

|

| CE | Parameter for Young's

modulus evolution. (Real) |

|

| fct_ID1 | Yield stress function

identifier 1 corresponding to strain rate

. (Integer) |

|

| fct_ID2 | Yield stress function

identifier 2 corresponding to strain rate

. (Integer) |

|

| fct_ID3 | Yield stress function

identifier 3 corresponding to strain rate

. (Integer) |

|

| fct_ID4 | Yield stress function

identifier 4 corresponding to strain rate

. (Integer) |

|

| fct_ID5 | Yield stress function

identifier 5 corresponding to strain rate

. (Integer) |

|

| fct_ID6 | Yield stress function

identifier 6 corresponding to strain rate

. (Integer) |

|

| fct_ID7 | Yield stress function

identifier 7 corresponding to strain rate

. (Integer) |

|

| fct_ID8 | Yield stress function

identifier 8 corresponding to strain rate

. (Integer) |

|

| fct_ID9 | Yield stress function

identifier 9 corresponding to strain rate

. (Integer) |

|

| fct_ID10 | Yield stress function

identifier 10 corresponding to strain rate

. (Integer) |

|

| Fscale1 | Scale factor for ordinate

(stress) in fct_ID1. Default = 1.0 (Real) |

|

| Fscale2 | Scale factor for ordinate

(stress) in fct_ID2. Default = 1.0 (Real) |

|

| Fscale3 | Scale factor for ordinate

(stress) in fct_ID3. Default = 1.0 (Real) |

|

| Fscale4 | Scale factor for ordinate

(stress) in fct_ID4. Default = 1.0 (Real) |

|

| Fscale5 | Scale factor for ordinate

(stress) in fct_ID5. Default = 1.0 (Real) |

|

| Fscale6 | Scale factor for ordinate

(stress) in fct_ID6. Default = 1.0 (Real) |

|

| Fscale7 | Scale factor for ordinate

(stress) in fct_ID7. Default = 1.0 (Real) |

|

| Fscale8 | Scale factor for ordinate

(stress) in fct_ID8. Default = 1.0 (Real) |

|

| Fscale9 | Scale factor for ordinate

(stress) in fct_ID9. Default = 1.0 (Real) |

|

| Fscale10 | Scale factor for ordinate

(stress) in fct_ID10. Default = 1.0 (Real) |

|

| Strain rate

1. (Real) |

||

| Strain rate

2. (Real) |

||

| Strain rate

3. (Real) |

||

| Strain rate

4. (Real) |

||

| Strain rate

5. (Real) |

||

| Strain rate

6. (Real) |

||

| Strain rate

7. (Real) |

||

| Strain rate

8. (Real) |

||

| Strain rate

9. (Real) |

||

| Strain rate

10. (Real) |

Example (Aluminum)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

g mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/LAW60/1/1

Aluminium_example

# RHO_I

.0027

# E Nu Eps_p_max Eps_t Eps_m

60400 .33 0 0 0

# N_funct F_smooth C_hard F_cut

4 0 0 0

# fct_IDp Fscale Fct_IDE EInf CE

0 0 0 0 0

# Funtions

1 2 3 4

# Scale factors Fscale_5

1 1.2 1.4 1.6

# Strain rates Eps_dot_5

0 20 30 40

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 3. FUNCTIONS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/1

function_36

# X Y

0 90

2.5E-4 100

.001 104

.009 121

.017 136

.021 143

.036 156

.045 162

.055 165

.072 170

.075 170

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/2

function_36

# X Y

0 90

2.5E-4 100

.001 104

.009 121

.017 136

.021 143

.036 156

.045 162

.055 165

.072 170

.075 170

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/3

function_36

# X Y

0 90

2.5E-4 100

.001 104

.009 121

.017 136

.021 143

.036 156

.045 162

.055 165

.072 170

.075 170

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/4

function_36

# X Y

0 90

2.5E-4 100

.001 104

.009 121

.017 136

.021 143

.036 156

.045 162

.055 165

.072 170

.075 170

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- The first point of yield stress functions (plastic strain versus stress) should have a plastic strain value of zero. If the last point of the first (static) function equals 0 in stress, default value of is set to the corresponding value of .

- If (plastic strain) reaches , in one integration point, the element is deleted.

- If (largest principal strain)

, stress is reduced using:

(1) - If , the element is deleted.

- The kinematic hardening model is not available in global formulation (hardening is fully isotropic).

- For kinematic hardening and strain rate dependency, yield stress depends on the strain rate.

- Strain rate filtering input (Fcut) is only available for shell and solid elements.

- Strain rate filtering is used to smooth strain rates.

- fct_IDp is used to distinguish the behavior in tension and compression for certain

materials (that is, pressure dependent yield). This is available for solid

elements only. The effective yield stress is then obtained by multiplying the

nominal yield stress by the yield factor corresponding to the actual

pressure.

Figure 1. - If , yield stress is a cubic interpolation between functions fn-1, fn, fn+1 and fn+2.

- If , yield stress is interpolated between functions , and .

- If , yield is extrapolated between functions fNfunc-3, fNfunc-2, fNfunc-1 and fNfunc.

- If

, yield is extrapolated between functions

fNfunc-2,

fNfunc-1 and

fNfunc.

Figure 2. - Functions describing strain dependence must be defined for different strain rates values.

- Strain rate values must be given in strictly ascending order.

- The evolution of Young's

modulus:

- If fct_IDE > 0, the curve defines a scale factor for Young's modulus evolution

with equivalent plastic strain, which means the Young's modulus is

scaled by the function

:

-

The initial value of the scale factor should be equal to 1 and it decreases.

- If fct_IDE = 0, the Young's modulus is calculated as:

(2)

-

Where,

E and Einf are respectively the initial and asymptotic value of Young's modulus, and is the accumulated equivalent plastic strain.Note:If fct_IDE = 0 and CE = 0, Young's modulus E is kept constant.

- If fct_IDE > 0, the curve defines a scale factor for Young's modulus evolution

with equivalent plastic strain, which means the Young's modulus is

scaled by the function

: