Running the Solver

Run the Solver by searching and navigating the documentation. Enable a parallel solution, save the model and run the Solver.

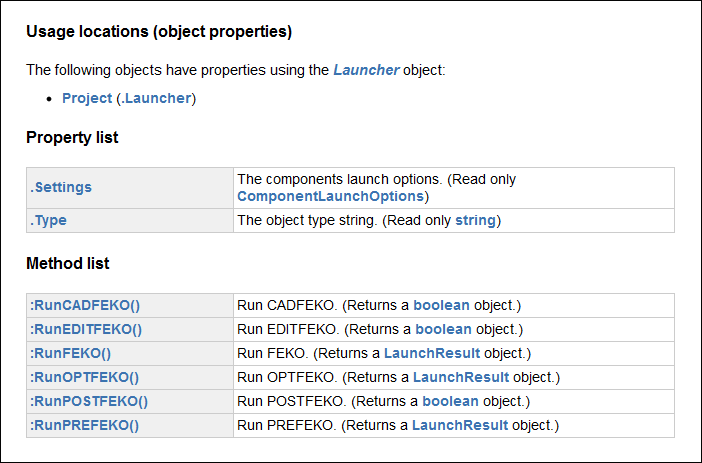

The results return in response to the runfeko query includes RunFEKO (method).

See what's new in the latest release.

The Feko Getting Started Guide contains step-by-step instructions on how to get started with Feko.

The Feko Example Guide contains a collection of examples that teaches you Feko concepts and essentials.

Simple examples demonstrating antenna synthesis and analysis.

Simple examples demonstrating antenna placement.

Simple examples demonstrating radar cross section (RCS) calculations of objects.

Simple examples demonstrating electromagnetic compatibility (EMC) analysis and cable coupling.

Simple examples demonstrating using waveguides and microwave circuits.

Simple examples demonstrating phantom and tissue exposure analsysis.

A simple example demonstrating the time analysis of an incident plane wave on an obstacle.

Simple examples demonstrating using continuous frequency range, using the MLFMM for large models, using the LE-PO (large element physical optics) on subparts of the model and optimising the waveguide pin feed location.

Simple examples demonstrating using Feko application automation, matching circuit generation with Optenni Lab and optimising a bandpass filter with HyperStudy.

Use application automation to perform operations with CADFEKO and POSTFEKO. Typical tasks include repetitive tasks, tasks that require several steps, or calculations.

Learn the terminology of automation to create an automation script.

Learn to navigate the API documentation to find the correct syntax for an automation script.

Learn to navigate the API documentation to create a patch antenna using an automation script.

Create a new empty project in CADFEKO.

Create a rectangle by searching and navigating the documentation.

Create a dielectric medium by searching and navigating the documentation.

Create a second dielectric medium by searching and navigating the documentation.

Create a planar multilayer substrate by searching and navigating the documentation.

Create a feed pin by searching and navigating the documentation.

Create a wire port by searching and navigating the documentation.

Create a voltage source by searching and navigating the documentation.

Set the frequency by searching and navigating the documentation.

Create the mesh by searching and navigating the documentation.

Create a far field request by searching and navigating the documentation.

Create a current request by searching and navigating the documentation.

Zoom to the extents of the 3D view to view the entire model and far field request.

Enable the parallel Solver by searching and navigating the documentation.

Save the CADFEKO model to a .cfx file by searching and navigating the documentation.

Run the Solver by searching and navigating the documentation. Enable a parallel solution, save the model and run the Solver.

View the completed CADFEKO automation script.

Post-process the results of a patch antenna on a multilayer substrate.

Increase productivity when dealing with predictable and repeatable POSTFEKO sessions (for example, exporting a report) using application automation. Use an automation script to configure a session and export a report that highlights the antenna properties of the model.

Design matching antenna circuits with Optenni Lab and use the circuit in Feko.

Design a bandpass coupled line filter with Altair HyperStudy as optimisation engine and Feko as the computational solver.

Feko is a comprehensive electromagnetic solver with multiple solution methods that is used for electromagnetic field analyses involving 3D objects of arbitrary shapes.

CADFEKO is used to create and mesh the geometry or model mesh, specify the solution settings and calculation requests in a graphical environment.

POSTFEKO, the Feko post processor, is used to display the model (configuration and mesh), results on graphs and 3D views.

EDITFEKO is used to construct advanced models (both the geometry and solution requirements) using a high-level scripting language which includes loops and conditional statements.

One of the key features in Feko is that it includes a broad set of unique and hybridised solution methods. Effective use of Feko features requires an understanding of the available methods.

Feko offers state-of-the-art optimisation engines based on generic algorithm (GA) and other methods, which can be used to automatically optimise the design and determine the optimum solution.

The Feko utilities consist of PREFEKO, OPTFEKO, ADAPTFEKO, the Launcher utility, Updater and the crash reporter.

Feko writes all the results to an ASCII output file .out as well as a binary output file .bof for usage by POSTFEKO. Use the .out file to obtain additional information about the solution.

A large collection of application macros are available for CADFEKO and POSTFEKO.

CADFEKO and POSTFEKO have a powerful, fast, lightweight scripting language integrated into the application allowing you to create models, get hold of simulation results and model configuration information as well as manipulation of data and automate repetitive tasks.

Reference information is provided in the appendix.

The Feko Example Guide contains a collection of examples that teaches you Feko concepts and essentials.

Simple examples demonstrating using Feko application automation, matching circuit generation with Optenni Lab and optimising a bandpass filter with HyperStudy.

Use application automation to perform operations with CADFEKO and POSTFEKO. Typical tasks include repetitive tasks, tasks that require several steps, or calculations.

Learn to navigate the API documentation to create a patch antenna using an automation script.

Run the Solver by searching and navigating the documentation. Enable a parallel solution, save the model and run the Solver.

Run the Solver by searching and navigating the documentation. Enable a parallel solution, save the model and run the Solver.

The results return in response to the runfeko query includes RunFEKO (method).

my_project.Launcher:RunFEKO()

(c) 2021. Altair Engineering Inc. All Rights Reserved.