Example: Automotive Application

For automotive applications, a target time step set to a value of 10 times the reference (nodal based constant) time step is a reasonable value to start with. However, greater than 20 times higher than the reference time step have been successfully utilized.

| Load Case | Vehicle Program | Radioss Version | Number of Cores | Model Zize | Original Nodal Time Step | Target Time Step | Speed-up v. Original Nodal Time Step | Comments | ODB Offset Deformable Barrier FFB Full Frontal Barrier (rigid) |

|---|---|---|---|---|---|---|---|---|---|

| Front crash | Neon public | 10.0.2 | 1M | 1 s | 10 s | 4 x | |||

| Taurus public FFB | 11.0.201 | 0.8 M | 0.5 s | 5 s | 2.83 x | Rigid wall replaced by rigid mesh and contact interface | |||

| OEM1 FFB | 11. | 24 x 1 | 1.3 M | 0.5 s | 5 s | 3 x | Figure 1 | ||

| OEM2 ODB | 11.0.230 | 32 x 1 | 2 M | 0.5 s | 5 s | 1.5 x | Figure 2 | ||

| OEM2 ODB | 11.0.230 | 6 x 6 | 2 M | 0.5 s | 5 s | 2 x | |||

| OEM4 FFB | 11.0 | 32 x 1 | 1.5 M | 0.5 s | 4 s | 1.9 x | |||

| OEM4 FFB | 11.0.230 | 8 x 6 | 6 M | 0.5  s s |

5  s s |

1.3 x | Rigid wall replaced by rigid mesh and contact interface | ||

| Rear crash | OEM1 | 11.0_sp | 16 x 1 | 1.1 M | 0.1 s | 2  s s |

5.8 x | Figure 3 | |

| OEM1 | 11.0 | 16 x 1 | 1.1 M | 0.1 s | 2 s |

6.5 x |

|||

| Side impact | OEM4 | 11.0 | 32 x 1 | 1 M | 0.5 s | 10 s | 2.1 x | Figure 4 | |

| Roof Crush | OEM4 | 11.0 | 16 x 1 | 1.2 M | 0.5 s | 10 s | 2.9 x | Figure 5 | |

| OEM4 | 11.0 | 32 x 1 | 1 M | 0.5 s | 10 s | 3.4 x | |||

| Taurus public | 11.0 | 16 x 1 | 0.8 M | 0.5 s | 10 s | 4.6 x | Figure 6 | ||

All speedup's compare original nodal time step double precision with AMS in single precision.

Automotive Related Results

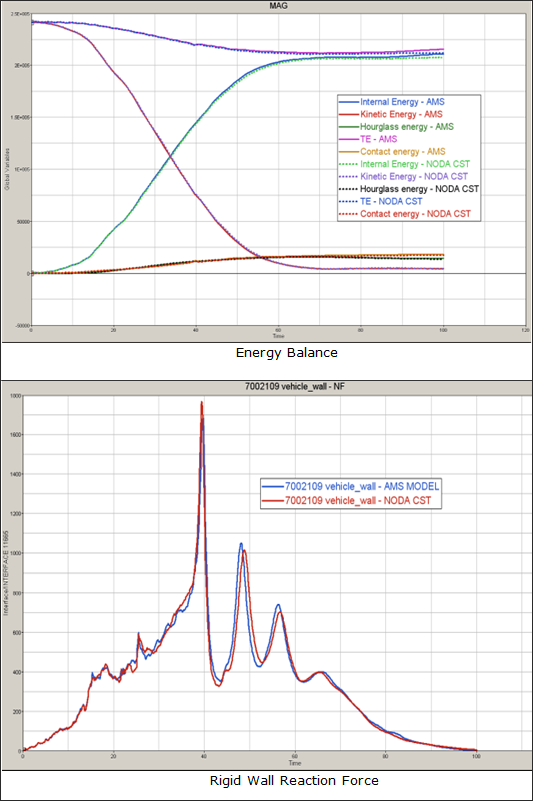

Figure 1. OEM1 Full Frontal

Figure 2. OEM2 Frontal Offset

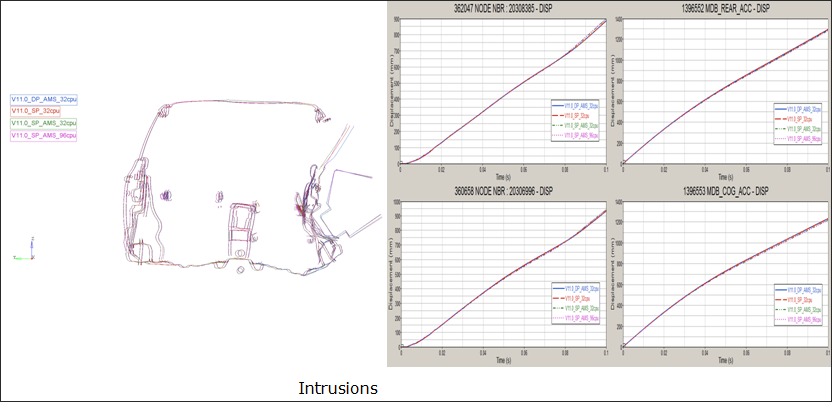

Figure 3. Front Rear Impact

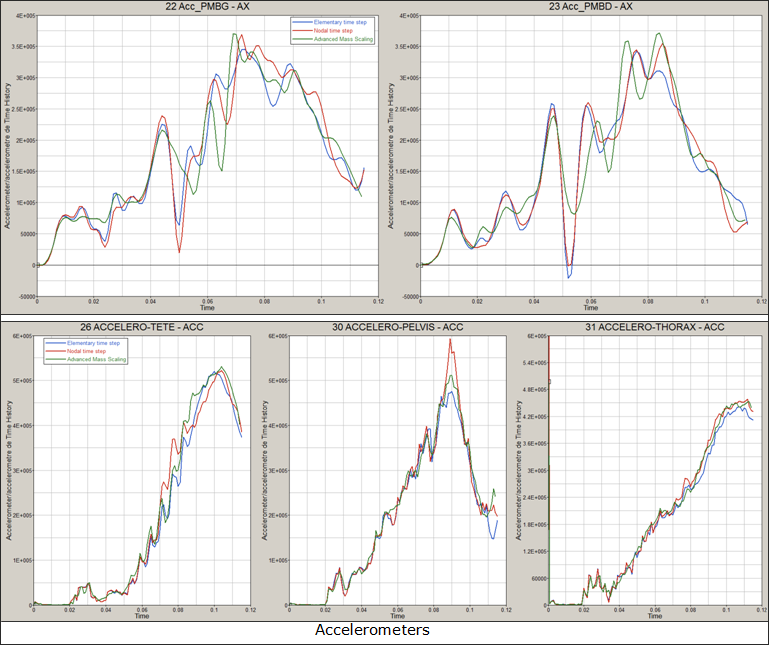

Figure 4. OEM4 Side Impact

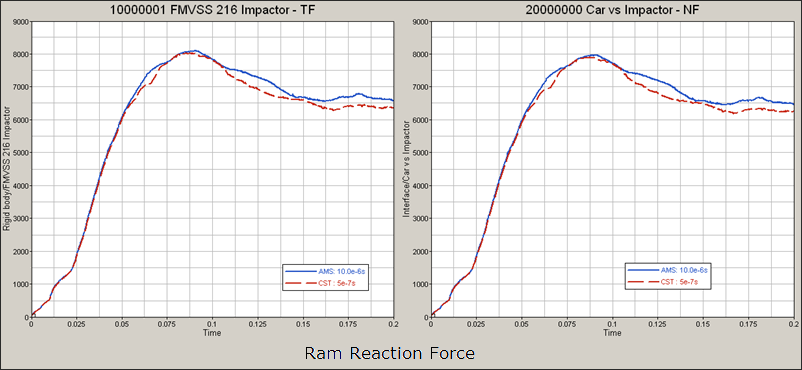

Figure 5. OEM4 Roof Crush

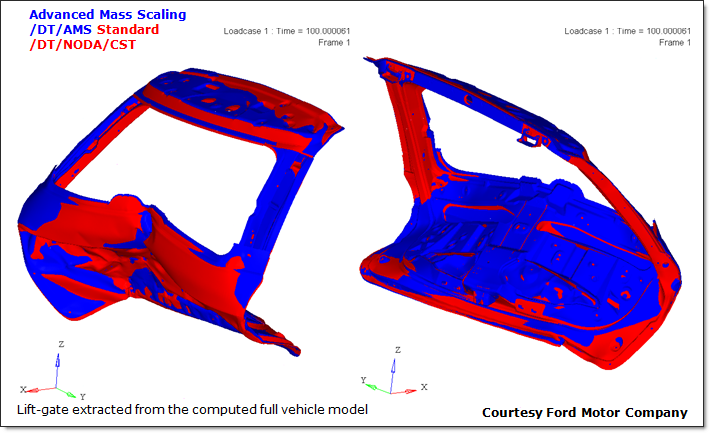

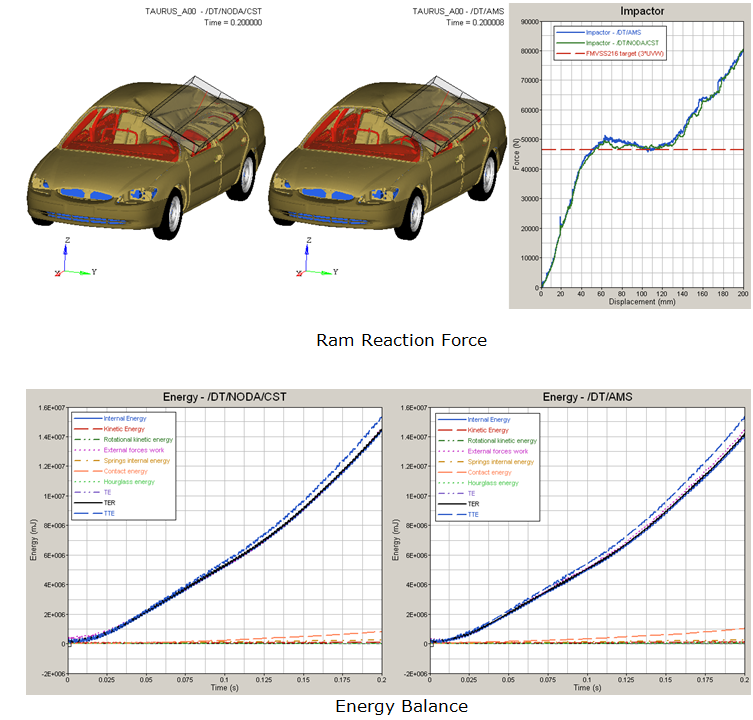

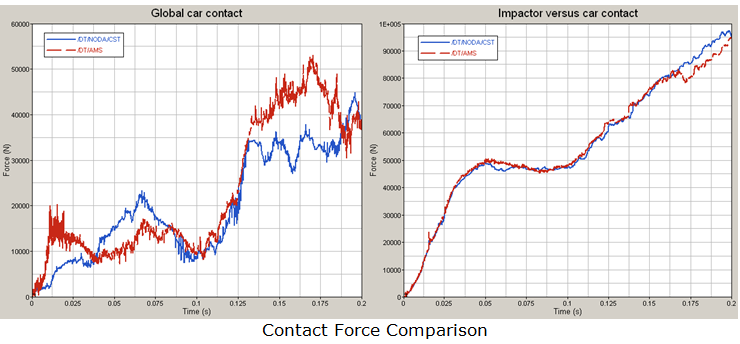

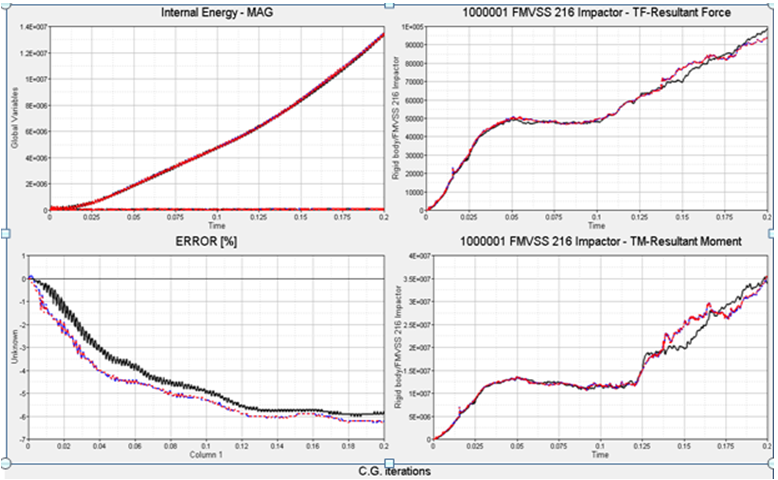

Figure 6. Ford Taurus Public Roof Crush

Figure 7.

| Load Case | Vehicle Program | Radioss Version | Number of Cores | Model Size | Original Nodal Time Step | Target Time Step | Speed-up v. Original Nodal Time Step | Comments | ODB Offset

Deformable Barrier FFB Full Frontal |

|---|---|---|---|---|---|---|---|---|---|

| Front crash | Neon public | 10.0.2 | 1M | 1 ms | 10 ms | 4 | Neon public | ||

| Taurus public FFB |

13.0 | 3 x 6 x 2 | 0.8 M | 0.5 ms /dt/inter/del 0.4 ms |

5 ms tol 0.001 /dt/inter/del 0.4 ms |

1.87 | Rigid wall replaced by rigid mesh and contact interface | ||

| OEM1 FFB | 11. | 24 x 1 | 1.3 M | 0.5 ms | 5 ms | 3 | |||

| OEM2 ODB | 11.0.230 | 32 x 1 | 2 M | 0.5 ms | 5 ms | 1.5 | |||

| OEM2 ODB | 13.0 | 3 x 6 x 2 | 2 M | 0.5 ms /dt/inter/del 0.1 ms |

5 ms tol 0.001 /dt/inter/del 0.1 ms |

1.51 | |||

| OEM4 FFB | 13.0 | 3 x 6 x 2 | 1.5 M | 0.5 ms /dt/inter/del 0.001 ms |

4 ms tol 0.001 /dt/inter/del 0.001 ms |

0.96 | |||

| OEM4 FFB | 11.0.230 | 3 x 6 x 2 | 6 M | 0.5 ms /dt/inter/del 0.1 ms |

5 ms /dt/inter/del 0.1 ms |

1.3 | Rigid wall replaced by rigid mesh and contact interface | ||

| Rear crash | OEM1 | 13.0 | 3 x 6 x 2 | 1.1 M | 0.1 ms /dt/inter/del 0.04 ms /dt/brick/cst 2.0 ms |

2 ms tol 0.001 /dt/inter/del 0.04 ms /dt/brick/cst 2.0 ms |

4.03 | ||

| Side impact | OEM4 | 13.0 | 3 x 6 x 2 | 1 M | 0.5 ms | 10 ms tol 0.001 | 2.11 | ||

| Roof Crush | OEM4 meshed | 13.0 | 3 x 6 x 2 | 1.2 M | 0.5 ms | 10 ms tol 0.001 | 2.83 | Rigid wall replaced by rigid mesh and contact interface | |

| OEM4 meshed | 13.0 | 3 x 6 x 2 | 1 M | 0.5 ms | 10 ms tol 0.001 | 1.13 | Rigid wall replaced by rigid mesh and contact interface | ||

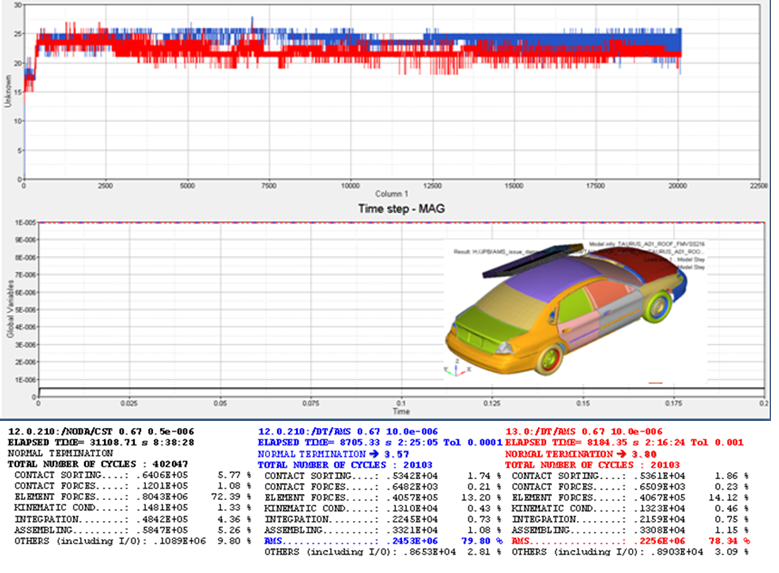

| Taurus public meshed rigid ram |

13.0 | 3 x 6 x 2 | 0.8 M | 0.5 ms | 10 ms tol 0.001 | 3.80 | Rigid wall replaced by rigid mesh and contact interface | ||

| Taurus public rigid wall ram |

13.0 | 3 x 6 x 2 | 0.8 M | 0.5 ms | 10 ms tol 0.001 | 2.18 | Rigid wall parallelepiped | ||

All speedup's compare original nodal time step with AMS both in double precision. The greyed rows relate to models that were not rerun in 13.0 and speedups belong to Table 2.

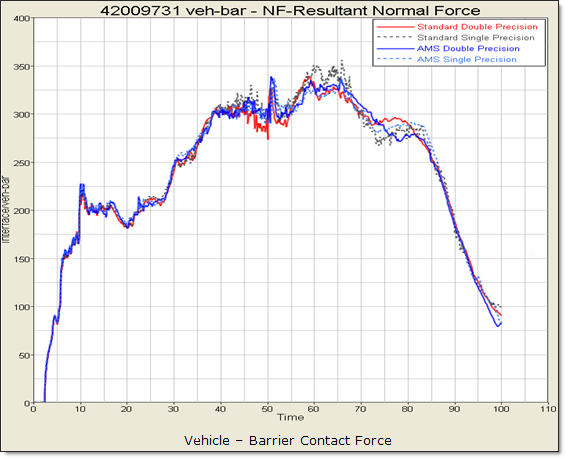

Figure 8. Ford Taurus Public Roof Crush