/GJOINT

Block Format Keyword Defines complex (gear-type) joints. This keyword is not available for SPMD computation.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /GJOINT/type/joint_ID/unit_ID | |||||||||

| joint_title | |||||||||

| node_ID0 | FscaleV | Mass | Inertia | node_ID1 | node_ID2 | node_ID3 | |||

| Mass1 | Inertia1 | r1x | r1y | r1z | |||||

| Mass2 | Inertia2 | r2x | r2y | r2z | |||||

| Mass3 | Inertia3 | r3x | r3y | r3z | |||||

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| type | Input type (see table below for available keywords) |

|

| joint_ID | Gear type joint

identifier (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier (Integer, maximum 10 digits) |

|

| joint_title | Gear type joint

title (Character, maximum 100 characters) |

|

| node_ID0 | Primary node identifier

(position node) (Integer) |

|

| FscaleV | Velocity scale

factor Default = 1.0 (Real) |

|

| Mass | Added mass to primary

node Default = 0.0 (Real) |

|

| Inertia | Added to primary node

inertia Default = 0.0 (Real) |

|

| node_ID1 | Node identifier N1 (Integer) |

|

| node_ID2 | Node identifier N2 (Integer) |

|

| node_ID3 | Node identifier N3 - only necessary for differential gear

joint. (Integer) |

|

| Mass1 | Added mass to node_ID1 Default = 0.0 (Real) |

|

| Inertia1 | Added to node_ID1 inertia Default = 0.0 (Real) |

] |

| r1x | Local axis X

component Default = 1.0 (Real) |

|

| r1y | Local axis Y

component Default = 0.0 (Real) |

|

| r1z | Local axis Z

component Default = 0.0 (Real) |

|

| Mass2 | Added mass to node_ID2 Default = 0.0 (Real) |

|

| Inertia | Added to node_ID2 inertia Default = 0.0 (Real) |

] |

| r2x | Local axis X

component Default = 1.0 (Real) |

|

| r2y | Local axis Y

component Default = 0.0 (Real) |

|

| r2z | Local axis Z

component Default = 0.0 (Real) |

|

| Mass3 | Added mass to node_ID3 Default = 0.0 (Real) |

|

| Inertia3 | Added to node_ID3 inertia Default = 0.0 (Real) |

] |

| r3x | Local axis X

component Default = 1.0 (Real) |

|

| r3y | Local axis Y

component Default = 0.0 (Real) |

|

| r3z | Local axis Z

component Default = 0.0 (Real) |

Complex Joint Types

- Type

- Description

- GEAR

- ∞ rotational gear

- DIFF

- ∞ differential gear

- RACK

- ∞ rack and pinion

Comments

- Complex (gear-type) joints belong to

the family of kinematic constraints treated by a Lagrange multipliers' method. A

joint position is defined by a central node_ID0,

which are connected to two or three secondary nodes. Mass and inertia must be

added to all nodes. It is advisable to place the primary node in the mass center

of the joint. Kinematic constraints impose relations between secondary nodes

velocities.

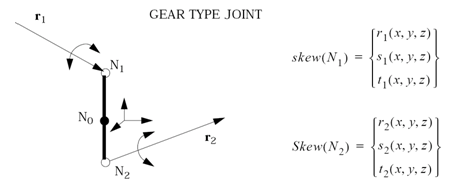

Figure 1. - Translational velocities of gear joint

nodes are constrained by a rigid link relation. For the rotational DOF, a scale

factor is imposed between velocities of node_ID1 and node_ID2, measured in their local coordinates. The

corresponding constraint equations are:

(1) (2) (3) (4) (5) Where, and are relative rotational velocities of node_ID1 and node_ID2 with respect to the rigid body rotational velocity.

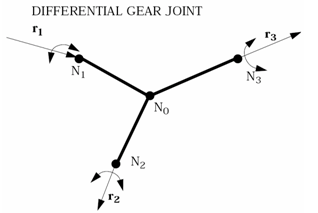

Figure 2. - The rotational velocities of a

differential gear joint are constrained by the relations:

(6) (7) (8)

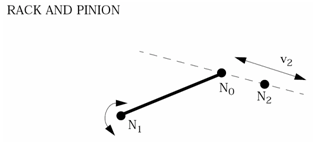

Figure 3. - The rack and pinion joint allows the

rotational velocity of node_ID1 to be transformed to a translational

velocity of node_ID2. The constraint equations for these

velocities are:

(9) (10) (11) - The node_ID3 is only necessary for a differential gear joint.

- This option is not available, if it is

applied on:

- a node with a null mass

- a node with a null inertia (except in case of node_ID2 of a rack type GJOINT)