/H3D/SHELL

Engine Keyword Generate H3D contour output results for /SHELL and /SH3N shell elements.

Format

/H3D/SHELL/Keyword3/Keyword4/Keyword5

#optional next line(s) that lists the parts to save results for.

part_ID1 ... part_IDN

Example

/H3D/SHELL/TENS/STRESS/PLY=1/NPT=ALL

/H3D/SHELL/TENS/STRESS/NPT=ALL/PLY=1/H3D/SHELL/TENS/STRESS/NPT=ALL/H3D/SHELL/ENER

356 293/H3D/SHELL/USER/NPT=ALL/UVAR=12Definitions

Comments

- The syntax /H3D/ELEM/Keyword3/Keyword4/Keyword5 is also valid.

- When PART IDs are listed after the /H3D/SHELL line the specified results will only be output for those parts.

- Output can be a, scalar, vector,

or tensor as defined in the following tables.

Table 1. Scalar Output Keyword3 Keyword4 Description ALPHA - PLY=

- I or ALL

- LAYER=

- I or ALL

Shear angle alpha of material /MAT/LAW58 in degrees. AMS Elements using AMS timestep due to /DT/CST_AMS. BULK Artificial Viscosity DAM1, DAM2, DAM3 Principal damage values in local orthotropic skew direction 1, 2 or 3 for materials LAW15 and LAW25. DAMA - MEMB

- PLY=

- I or ALL

- LAYER=

- I or ALL

- NPT=

- I, ALL, LOWER or UPPER

Maximum of damage over time of all /FAIL criteria acting on one material. Refer to the specific /FAIL law used for how damage is calculated. DENS Density DOMAIN SPMD domain number of an element. DT Element timestep ENER Specific energy density (internal energy divided by the element mass) EPSD Equivalent strain rate EPSP - PLY=

- I or ALL

- LAYER=

- I or ALL

- NPT=

- I, ALL, LOWER or UPPER

Plastic strain ERROR THICK Estimated error on shell thickness FAIL - PLY=

- I or ALL

Number of failed layers for /PROP/TYPE10, /PROP/TYPE11, /PROP/TYPE17, /PROP/TYPE51, /PCOMPP, /MAT/LAW15 and /MAT/LAW25. For the other property sets and material laws the values are: no failure =0 and element failed =1. FLDF - MEMB

- LAYER=

- I or ALL

- NPT=

- I, ALL, LOWER or UPPER

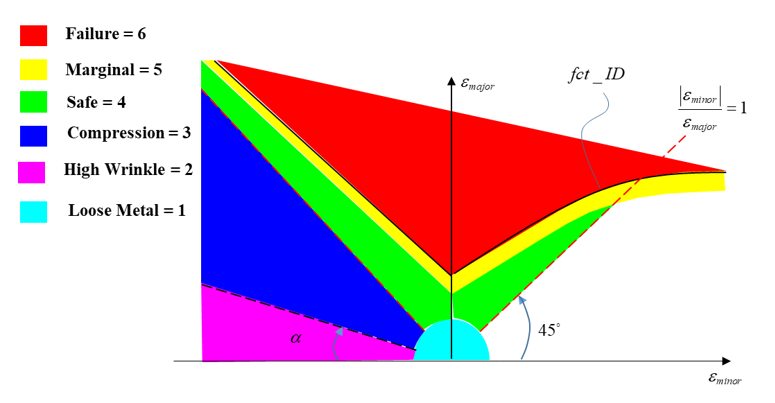

FLD damage factor indicator. 6 FLDZ - MEMB

- LAYER=

- I or ALL

- NPT=

- I, ALL, LOWER or UPPER

FLD failure zone factor for the FLD failure model. 7 - = 1

- Loose metal

- = 2

- HIgh wrinkle

- = 3

- Compression

- = 4

- Safe

- = 5

- Marginal

- = 6

- Failure

HOURGLASS Hourglass Energy MASS Element mass NXTF - MEMB

- LAYER=

- I or ALL

- NPT=

- I, ALL, LOWER or UPPER

Instability factor of /FAIL/NXT failure model OFF Element status. Where the result output is:- = -1

- Element is not active (it is defined in an activated rigid body).

- = 0

- Deleted element.

- Between 0 and 1

- Under failure process.

- = 1

- Active element.

PHI - MEMB

- PLY=

- I or ALL

- NPT=

- I, ALL, LOWER or UPPER

Angle between the element system and direction 1 orthotropy SIGEQ Equivalent stress based on a material’s yield criteria. Some examples of yield criteria are von Mises, Hill or Barlat. SIGX, SIGY, SIGZ, SIGXY, SIGYZ, SIGZX Stress in specified direction TDEL Time at which element is deleted, due to failure defined using /FAIL criterion. Failure criteria built in materials is ignored. TEMP Temperature THICK Thickness THIN % thinning for shell. USER - PLY=

- I or ALL

- LAYER=

- I or ALL

- NPT=

- I, ALL, LOWER or UPPER

- UVAR=

- I or ALL

User material (/MAT/USERij) law output for user defined variable i. Also, requests USR output for some Radioss material laws such as LAW58. USR1 output is requested using UVAR=1. VONM von Mises stress at neutral fiber WPLA - PLY=

- I or ALL

- LAYER=

- I or ALL

- NPT=

- I, ALL, LOWER or UPPER

Plastic work for /MAT/LAW15 (CHANG) and /MAT/LAW25 (COMPSH) Table 2. Tensor Output Keyword3 Keyword4 Keyword5 Description TENS EPSDOT - MEMB

- BEND

- PLY=

- I or ALL

- LAYER=

- I or ALL

- NPT=

- I or ALL

Strain rate tensor STRAIN - MEMB

- BEND

- PLY=

- I or ALL

- LAYER=

- I or ALL

- NPT=

- I, ALL, LOWER or UPPER

Strain tensor STRAIN_ENG -- Infinitesimal total strain. Only one tensor per element. STRESS - MEMB

- BEND

- PLY=

- I or ALL

- LAYER=

- I or ALL

- NPT=

- I or ALL

Stress tensor - The output location in

Keyword4 and Keyword5 can be defined

via:

- NPT

- Integration points.

- LAYER

- Composite shell layer when using /PROP/TYPE11 (SH_SANDW), /PROP/TYPE10 (SH_COMP).

- PLY

- Composite shell ply when using, /PROP/TYPE19 (PLY) or /PLY.

- MEMB

- Generalized membrane stresses per element. Cannot be used with NPT, LAYER or PLY options.

- BEND

- Generalized bending stresses per element. Cannot be used with NPT, LAYER or PLY options.

- Output can be requested for a specific location number (I), ALL, and in some case UPPER or LOWER. The output locations are separated by a / and can be in any order.

- The values of FLD damage factor

is equal to the ratio of the actual major principal strain value over the

forming limit curve value:

(1) Where, is the major principal strain at failure limit from FLD diagram (fct_ID in /FAIL/FLD).

The FLD compares the and using the same .

Figure 1.FLDF may be greater than 1, if the option /FAIL/FLD, Ifail_sh=4 is used. In this case, the damage factor is only calculated for post-processing and no elements are deleted.

- The values of FLD zone index are

defined as:

- FLDZ=6

- Failure

- FLDZ=5

- Marginal

- FLDZ=4

- Safe

- FLDZ=3

- Compression

- FLDZ=2

- High wrinkle

- FLDZ=1

- Loose metal

Figure 2.Where,- fct_ID

- Defined in /FAIL/FLD

- Major strain as a limit from FLD diagram from fct_ID in /FAIL/FLD

- and

- The minimum and maximum principal strains

- Rani

- Average anisotropy factor defined in FLD input in /FAIL/FLD

- Defined in FLD input in /FAIL/FLD

- Defined in FLD input in /FAIL/FLD

(2) - I_marg

- Defined in FLD input in /FAIL/FLD