/DSIZE

Optimization Keyword Defines parameters for the generation of free-size design variables.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /DSIZE/dsize_ID | |||||||||

| title | |||||||||

| grpart_ID | THICK | STRES | MEMBSIZ | PATRN | PATREP | NGROUP | COMP | ||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| T0 | T1 | ||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MAXSTRS | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| MINDIM | |||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| TYP | AID | XA | YA | ZA | |||||

| FIX | XF | YF | ZF | ||||||

| UCYC | SID | XS | YS | ZS | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| ptrepCID | |||||||||

| CAID | XCA | YCA | ZCA | ||||||

| CFID | XCF | YCF | ZCF | ||||||

| CSID | XCS | YCS | ZCS | ||||||

| CTID | XCT | YCT | ZCT | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| mainID | SX | SY | SZ | ||||||

| ptreCID | |||||||||

| CAID | XCA | YCA | ZCA | ||||||

| CFID | XCF | YCF | ZCF | ||||||

| CSID | XCS | YCS | ZCS | ||||||

| CTID | XCT | YCT | ZCT | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| CTYP=1: | |||||||||

| CTYP | LTMIN | LTMAX | grsh3n_ID | grshel_ID | LTEXC | ||||

| CTYP=2: | |||||||||

| CTYP | PTANGLE | PTMIN | PTMAX | grsh3n_ID | grshel_ID | PTEXC | |||

| CTYP=3: | |||||||||

| CTYP | PPANGLE | PPMIN | PPMAX | grsh3n_ID | grshel_ID | PPEXC | |||

| CTYP=4: | |||||||||

| CTYP | PMANGLE | PMMAN | grsh3n_ID | grshel_ID | PMEXC | ||||

| CTYP=5: | |||||||||

| CTYP | BANGLE1 | BANGLE2 | |||||||

| CTYP=6: | |||||||||

| CTYP | CANGLE | CTHICK | |||||||

| CTYP=7: | |||||||||

| CTYP | PDANGLE | PDTYP | PDMAX | grsh3n_ID | grshel_ID | PDEXC | |||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| ETYP1 | EGRP1 | ||||||||

| ETYP2 | EGRP2 | ||||||||

| etc | etc |

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| dsize_ID | Free-size design variable

identifier. (Integer > 0) |

|

| title | Title. (Character, maximum 100 characters) |

|

| grpart_ID | Part group identifier

defining the design space. (Integer > 0) |

|

| THICK | Indicates if minimum and

possibly maximum thickness values need to be defined.

(Integer ≥ 0) |

|

| T0 | Minimum thickness. (Real > 0.0 or blank) |

|

| T1 | Maximum thickness. (Real > 0.0 or blank) |

|

| STRESS | Indicates if von Mises

stress constraint needs to be defined.

(Integer) |

|

| MAXSTRS | Upper bound constraint on

von Mises stress. No default (Real > 0.0) |

|

| MEMBSIZ | Active member size control flag.

(Integer ≥ 0) |

|

| MINDIM | Minimum diameter of

members formed is specified. This field can be used to eliminate

small members. It also eliminates checkerboard results. Default = No minimum member size control (Real > 0.0) |

|

| PATRN | Active pattern grouping flag.

(Integer) |

|

| TYP | Pattern grouping type requested.

Default = No pattern grouping (Integer) |

|

| AID | Variable pattern grouping

anchor node identifier.

(Integer > 0 or blank) |

|

| XA, YA, ZA | Coordinates of the pattern

grouping anchor point.

(Real or blank) |

|

| FID | Node identifier that

defines the direction of the first vector for variable pattern

grouping.

(Integer > 0 or blank) |

|

| XF, YF, ZF | Components of the first

vector that defines pattern grouping.

(Real or blank) |

|

| UCYC | Number of cyclical

repetitions for cyclical symmetry. This field defines the number of

radial "wedges" for cyclical symmetry. The angle of each wedge is

computed as: 360.0/UCYC. Default = blank (Integer > 0 or blank) |

|

| SID | Node identifier of the

second point for pattern grouping definition.

(Integer or blank) |

|

| XS, YS, ZS | Coordinates of the second

point for pattern grouping definition.

(Real or blank) |

|

| PATREP | Indicates if pattern

repetition is defined and repetition type.

(Integer) |

|

| mainID | Main

/DSIZE identifier for pattern

definition. This field is required only for PATREP =2. (Integer > 0) |

|

| SX, SY, SZ | Scale factors for pattern

repetition in the X, Y, and Z directions, respectively. Default = 1.0 (Real > 0.0) |

|

| ptrepCID | Skew identifier used as

the pattern repetition coordinate system. Default = 0 (Integer > 0) |

|

| CAID | Node identifier of an

anchor point for the definition of a pattern repetition coordinate

system.

(Integer > 0 or blank) |

|

| XCA, YCA, ZCA | Coordinates of an anchor

point for the definition of a pattern repetition coordinate

system.

(Real or blank) |

|

| CFID | Node identifier of the

first point for the definition of a pattern repetition coordinate

system.

(Integer > 0 or blank) |

|

| XCF, YCF, ZCF | Coordinates of the first

point for the definition of a pattern repetition coordinate

system.

(Real or blank) |

|

| CSID | Node identifier of a

second point for the definition of a pattern repetition coordinate

system.

(Integer > 0 or blank) |

|

| XCS, YCS, ZCS | Coordinates of a second

point for the definition of a pattern repetition coordinate

system.

(Real or blank) |

|

| CTID | Node identifier of a third

point for the definition of a pattern repetition coordinate

system.

(Integer > 0 or blank) |

|

| XCT, YCT, ZCT | Coordinates of a third

point for the definition of a pattern repetition coordinate

system.

(Real or blank) |

|

| NGROUP | Number of element groups

used in zone based free-sizing optimization. Default = 0 (Integer ≥ 0) |

|

| ETYPi | Type of followed element group.

(Integer > 0), i=1, ..., NGROUP |

|

| EGRPi | Element group numbers used

in zone based free-sizing optimization. (Integer > 0), i=1, ...,NGROUP |

|

| COMP | Composite manufacturing constraints applied are indicated. Information about manufacturing constraints is to follow. The value of COMP is equal to the total number of composite manufacturing definitions that follow. | |

| CTYP | Composite manufacturing

type definition flag.

(Integer) |

|

| LTMIN | Minimum laminate thickness

for the laminate thickness constraint (CTYP =

1). (Real or blank) |

|

| LTMAX | Maximum laminate thickness

for the laminate thickness constraint (CTYP =

1). (Real or blank) |

|

| grsh3n_ID | 3-node shell group

identifier. (Integer > 0) |

|

| grshel_ID | 4-node shell group

identifier. (Integer > 0) |

|

| LTEXC | Indicates that certain

plies are excluded from the laminate thickness constraint

(CTYP = 1). Support options are:

(Integer) |

|

| PTANGLE | Ply orientation in degrees

to which the ply thickness constraint (CTYP =

2) is applied. (Real) |

|

| PTMIN | Minimum thickness for the

ply thickness constraint (CTYP =

2). (Real or blank) |

|

| PTMAX | Maximum thickness for the

ply thickness constraint (CTYP =

2). (Real or blank) |

|

| PTEXC | Indicates that certain

plies are excluded from the ply thickness constraint

(CTYP = 2). Supported

options are:

(Integer) |

|

| PPANGLE | Ply orientation in degrees

to which the ply thickness percentage constraint is applied

(CTYP =

3). (Real) |

|

| PPMIN | Minimum percentage

thickness for the ply thickness percentage constraint

(CTYP = 3). (Real or blank) |

|

| PPMAX | Maximum percentage

thickness for the ply thickness percentage constraint

(CTYP = 3). (Real or blank) |

|

| PPEXC | Indicates that certain

plies are excluded from the ply thickness percentage constraint

(CTYP = 3). Supported

options are:

(Integer) |

|

| PMANGLE | Ply orientation in degrees

to which the manufacturable ply thickness constraint is applied

(CTYP =

4). (Real) |

|

| PMMAN | Manufacturable ply

thickness. Default = blank (Real > 0.0) |

|

| PMEXC | Indicates that certain

plies are excluded from the manufacturable ply thickness constraint

(CTYP = 4). Supported

options are:

(Integer) |

|

| BANGLE1 | First ply orientation in

degrees to which the balance constraint is applied

(CTYP =

5). (Real) |

|

| BANGLE2 | Second ply orientation in

degrees to which the balance constraint is applied

(CTYP =

5). (Real) |

|

| CANGLE | Ply orientation in degrees

to which the constant thickness constraint is applied

(CTYP =

6). (Real) |

|

| CTHICK | Constant ply thickness for

the constant thickness constraint (CTYP =

6). (Real) |

|

| PDANGLE | Ply orientation in degrees

to which the ply drop-off constraint is applied

(CTYP =

7). (Real) |

|

| PDTYP | Drop-off constraint type:

2

(Integer) |

|

| PDMAX | Maximum allowed drop-off

for the ply drop-off constraint (CTYP =

7). (Real) |

|

| PDEXC | Indicates that certain

plies are excluded from the ply drop-off constraint

(CTYP = 7). Supported

options are:

(Integer) |

Example

# Free size parameters

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/DSIZE/3000

freeSizeOpti

### COPM=6: 6 composite manufacturing constraints are applied

### CTYP=3: Ply thickness percentage constraints are applied

### CTYP=4: Manufacturable ply thickness constraints are applied.

### CTYP=5: A balance constraint is applied.

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

# grpartID THICK STRESS MEMBSIZ PATRN PATREP NGROUP COMP

10001 0 0 0 0 0 0 6

# CTYP=3 PPANGLE PPMIN PPMAX grsh3n_ID grshel_ID PPEXC

3 0. 0. 0.8

# CTYP=4 PMANGLE PMMAN grsh3n_ID grshel_ID PMEXC

4 0. 0.1

# CTYP=4 PMANGLE PMMAN grsh3n_ID grshel_ID PMEXC

4 45.0 0.1

# CTYP=4 PMANGLE PMMAN grsh3n_ID grshel_ID PMEXC

4 -45.0 0.1

# CTYP=4 PMANGLE PMMAN grsh3n_ID grshel_ID PMEXC

4 90. 0.1

# CTYP=5 BANGLE1 BANGLE2

5 45.0 -45.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- This entry is represented as an optimization objective in HyperMesh and HyperCrash.

- The options for selecting the type

of drop-off constraints for PDTYP are defined for a set of

plies.The PDTYP options are:

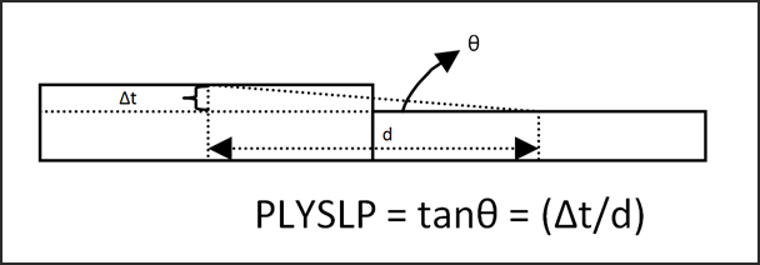

- PLYSLP

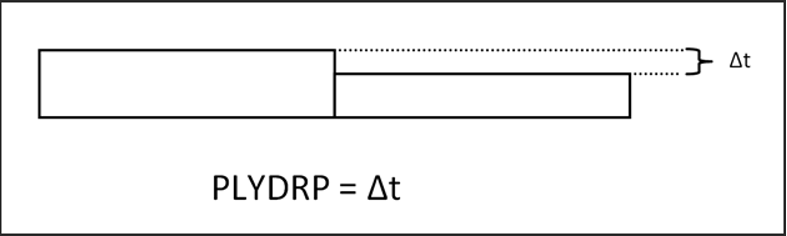

- PLYDRP

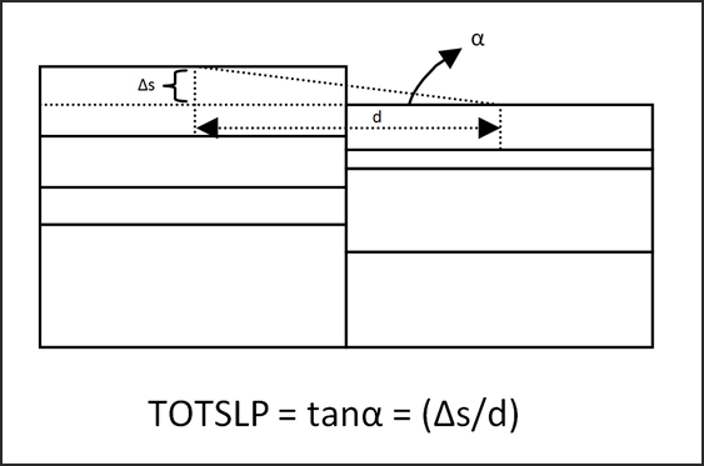

- TOTSLP

- TOTDRP

Figure 1.Assuming that the plies are stacked as shown above, the following definition is:

Figure 2.

Figure 3.

Figure 4.

Figure 5.