Incremental_RADIOSS Macro Menu |

|

|

|

|

|

Incremental_RADIOSS Macro Menu |

|

|

|

|

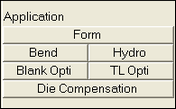

The Incremental_RADIOSS macros are grouped based on the application, although several of them are common for different applications. The selected macro in the Application group determines which macros appear below.

Application |

||

Form |

Lets you set up a single-stage forming analysis. |

|

Bend |

Lets you set up a rotary draw tube bending and triggers the following buttons under the Setup grouping: |

|

Bending Model Creator |

|

|

Bending Setup |

Defines the parameters for a tube bending analysis. |

|

List |

Displays a table summarizing the attributes for different components in the model. The component attributes can be easily modified by editing this table. |

|

Spherical joint |

Creates a spherical joint. |

|

Hydro |

Lets you set up a hydroforming analysis. Triggers the following buttons under the Setup grouping: |

|

Import STA |

|

|

Rename |

|

|

Import Tooling |

|

|

Hydro Setup |

Lets you define the parameters for a hydroforming analysis. |

|

Blank Optimizer |

Submenu of macros that help you optimize a mesh so that it follows the trim line as closely as possible. |

|

TL Opti |

Lets you trim by elements or components. The trimming by components option can trim only the elements inside the trim line. |

|

Die Compensation |

Compensates for die springback on the blank. |

|

Model |

||

HF |

Imports a file saved in an earlier session. |

|

CAD |

Imports external CAD files. Commonly used, supported file formats include: CATIA, IGES, STL, PDGS, VDAFS, UG18 and UG_NX. |

|

FE |

Imports input decks corresponding to different FE solvers. Commonly used, supported solver formats include: OptiStruct, Nastran, ANSYS, Abaqus, LS-DYNA, RADIOSS, PAM-CRASH 2G, MoldFlow, etc. |

|

Remove Holes |

Identifies all pinholes < 100mm diameter on the displayed surfaces and allows you to delete them. |

|

R-Mesh |

Opens the R Mesh macro. |

|

B-Mesh |

Opens the Blank Surface Meshing dialog, on which you can specify an average edge length and mesh selected surfaces. |

|

Check Elems |

Lets you verify the basic quality of your elements and the geometric qualities of those elements. |

|

Setup |

||

Sections |

Lets you define section properties, including thickness. |

|

Materials |

Lets you define material properties. |

|

Database… |

Lets you define materials and review the material’s properties. |

|

Comps |

Lets you create tool and blank components and assign their section and material properties. |

|

List… |

Displays a table summarizing the attributes for different components in the model. The component attributes can be easily modified by editing the table. |

|

Symmetry... |

Lets you define the symmetry planes in a model. |

|

Constraints |

Lets you define boundary conditions. |

|

Tool Setup |

Automatically creates and positions the tools for stamping analysis. |

|

Tool Motion |

Lets you define the tool motion parameters, as well as the solution control and output history parameters. |

|

Tool Load |

Lets you define the force on a blankholder or pad, and activates a rigid body stopper. |

|

Drawbeads |

Lets you define the drawbeads and the corresponding restraining forces. Either a line or a set of nodes may be used to describe the drawbead location. |

|

Editor... |

Opens the Drawbeads Editor. |

|

Contacts |

Lets you set up either single or multiple contact definitions between the blank and tools. |

|

Save |

Saves your file. |

|

Run |

Launches a Dyna analysis and lets you select the component for which a Dyna ASCII output is required during subsequent analysis. From here, you can also get a summary of your model and a preview of the tool motion before launching the analysis. |

|

Auto Process |

Provides an easy-to-use setup for various process types. The Auto Process macro prompts you for all necessary parameters for a given analysis type. |

|

Multi-stage Manager |

Provides a convenient graphical setup for process sequences that include multiple stages of processing. The Multi-stage Manager also enables you to define the parameters for each process stage. |

|

Results |

||

Load Results |

Lets you directly launch the post processor (HyperView) with the results for the current model. |

|

Report Generator |

Creates an HTML-based or PowerPoint presentation containing results from the forming analysis. Choose from among five result types and export as H3D, JPEG, or AVI files. Note: End users reviewing the resulting report must have HyperView Player (7.0 SP1,SA-042 and above) installed to take full advantage of the animation features in the report. |

|