Turbulent Flow Past a Wall-Mounted Hump

In this application, AcuSolve is used to simulate fully developed turbulent flow past a smooth hump on the lower wall of a flow domain. AcuSolve results are compared with experimental results as described in Seifert and Pack (2002) and on the NASA Langley Research Center Turbulence Modeling Resource web page. The close agreement of AcuSolve results with experimental data and reference turbulence model performance validates the ability of AcuSolve to model cases with turbulent flow moving past a wall protrusion resulting in flow separation and recovery.

Problem Description

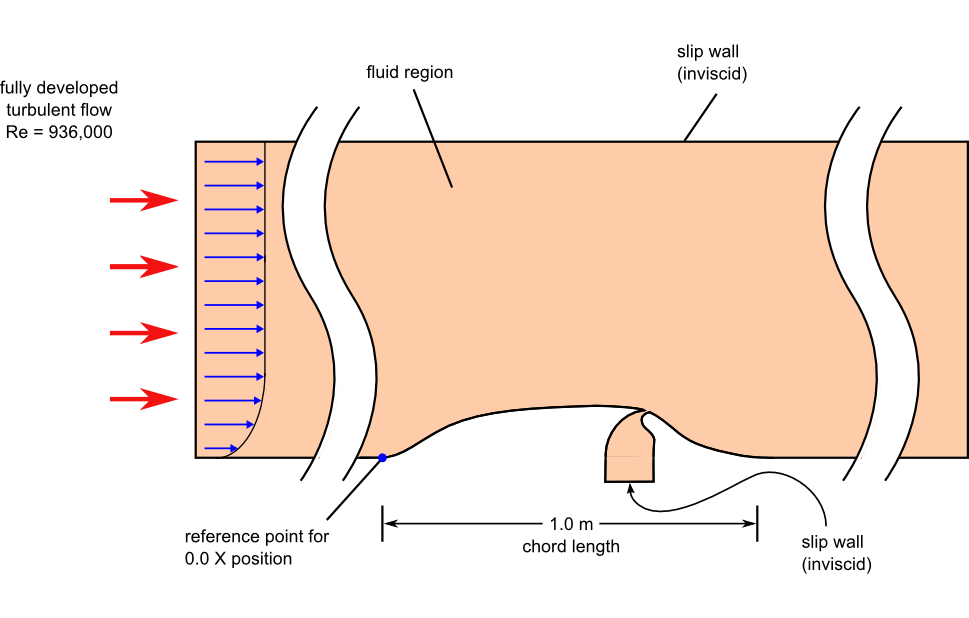

Figure 1. Critical Dimensions and Parameters for Simulating Turbulent Flow Through a Domain with a Wall-Mounted Hump

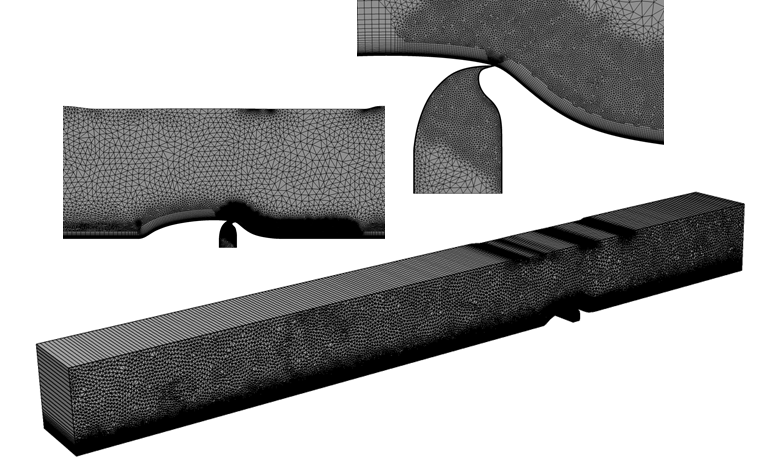

Figure 2. Three Views of the Mesh Used for Simulating Turbulent Flow over a Wall-Mounted Hump (Full Mesh is Shown on the Bottom, with Increased Resolution in Clockwise Views)

AcuSolve Results

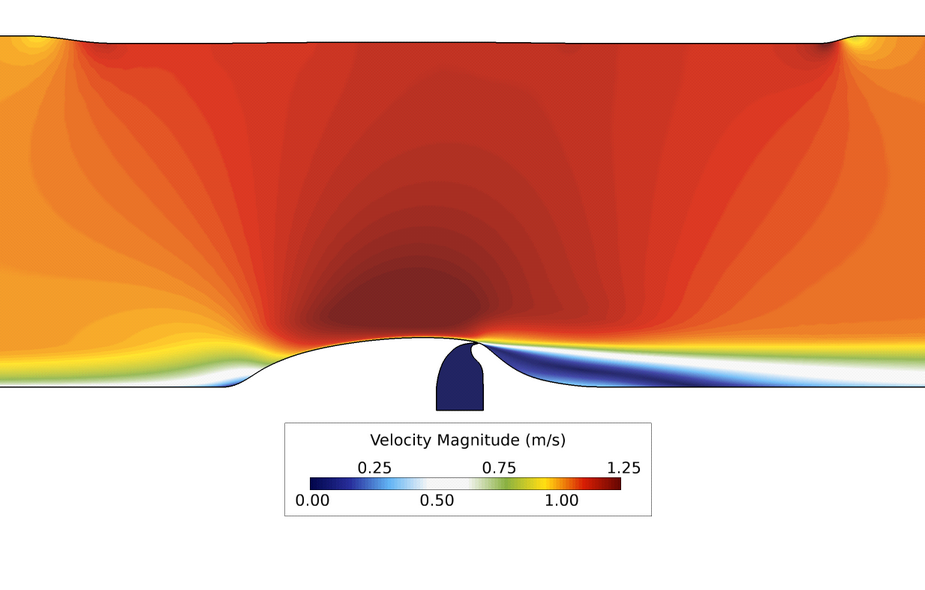

Figure 3. Velocity Contours on the Boundaries of the Domain, Showing Velocity Magnitude

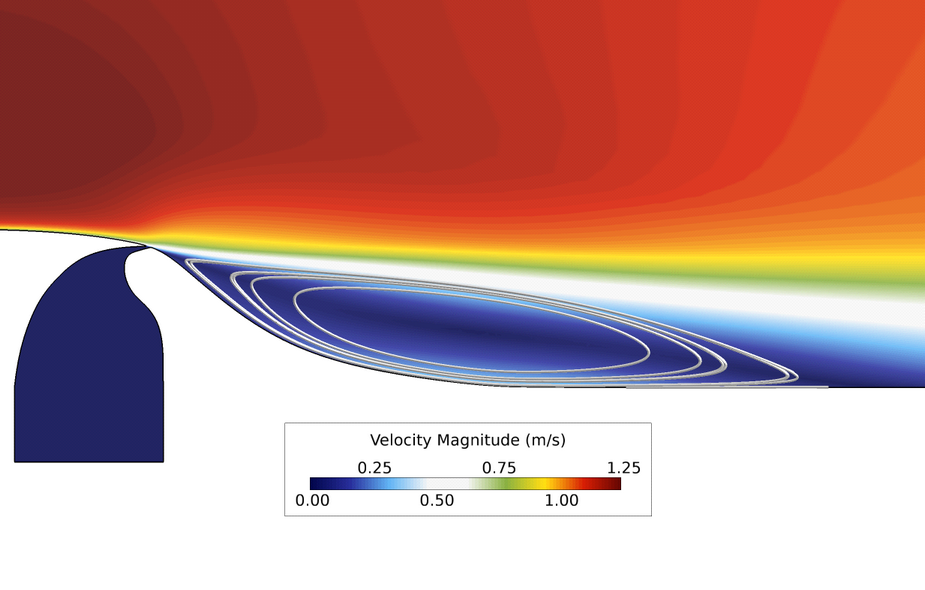

Figure 4. Close up View of Velocity Contours Showing the Recirculation Region with Streamlines (White Lines) Representing the Region of Backflow

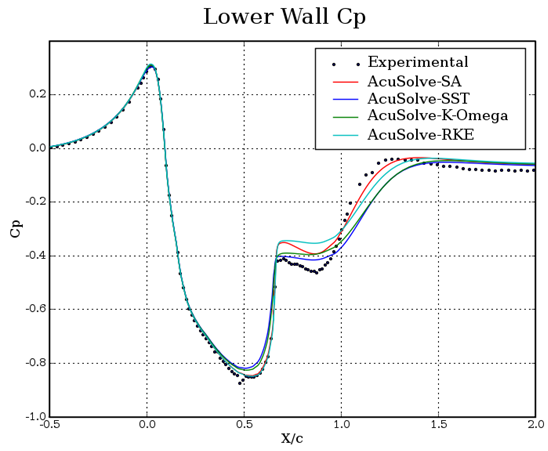

Figure 5. Coefficient of Pressure Along the Lower Wall as the Flow Moves Past the Hump, Where c is the Hump Chord Length and 0.0 is the Reference Location at the Front of the Hump in the X-Direction (Streamwise)

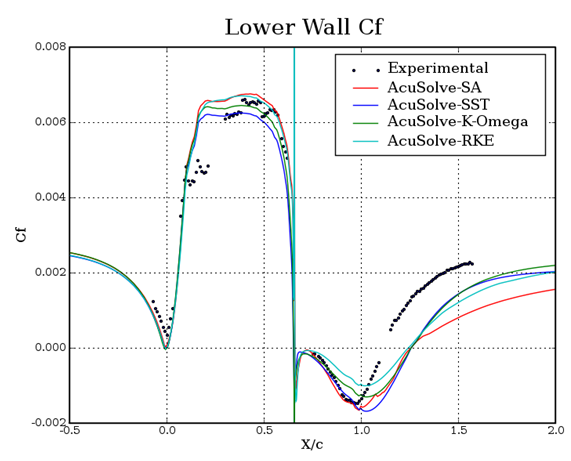

Figure 6. Skin Friction Coefficient Along the Lower Wall as the Flow Moves Past the Hump, Where c is the Hump Chord Length and 0.0 is the Reference Location at the Front of the Hump in the X-Direction (Streamwise)

Summary

In this application, a bulk turbulent flow at a Reynolds number of 936,000 within a flow domain containing a wall-mounted hump is studied and compared against experimental data. The AcuSolve results compare well with the experimental data for pressure coefficient and skin friction coefficient near the hump and downstream. The performance of the three turbulence models were found to be consistent with previously published results for flow over a wall-mounted hump (NASA 2015). For this application, the two equation models appear to outperform the one equation turbulence model, with better agreement for the downstream pressure on the wall. This application demonstrates AcuSolve's ability to predict the distribution of pressure and shear stress on protruding bodies within a turbulent flow field and serves to validate current turbulence modeling capabilities.

Simulation Settings for Turbulent Flow past a Wall-Mounted Hump

AcuConsole database file: <your working directory>\wall_mounted_hump_turbulent\wall_mounted_hump_turbulent.acs

Global

- Problem Description

- Analysis type - Steady State

- Turbulence equation - Spalart Allmaras

- Auto Solution Strategy

- Max time steps - 100

- Convergence tolerance - 0.001

- Relaxation factor - 0.4

- Material Model

- Fluid

- Density - 1.0 kg/m3

- Viscosity - 1.0684e-6 kg/m-sec

Model

- Fluid

- Volumes

- Fluid

- Element Set

- Material model - Fluid

- Element Set

- Fluid

- Surfaces

- +Y

- Simple Boundary Condition

- Type - Slip

- Simple Boundary Condition

- -Y

- Simple Boundary Condition

- Type - Slip

- Simple Boundary Condition

- Cavity walls

- Simple Boundary Condition

- Type - Wall

- Turbulence wall type - Wall Function

- Simple Boundary Condition

- Hump walls

- Simple Boundary Condition

- Type - Wall

- Turbulence wall type - Wall Function

- Simple Boundary Condition

- Hump walls - downstream

- Simple Boundary Condition

- Type - Wall

- Turbulence wall type - Wall Function

- Simple Boundary Condition

- Inlet

- Simple Boundary Condition

- Type - Inflow

- Inflow type - Velocity

- Inflow velocity type - Cartesian

- X Velocity - 1.0 m/sec

- Turbulence input type - Direct

- Eddy viscosity - 3.205128e-6 m2/sec

- Simple Boundary Condition

- Lower slip

- Simple Boundary Condition

- Type - Slip

- Simple Boundary Condition

- Lower wall

- Simple Boundary Condition

- Type - Wall

- Turbulence wall type - Wall Function

- Simple Boundary Condition

- Nozzle walls

- Simple Boundary Condition

- Type - Wall

- Turbulence wall type - Wall Function

- Simple Boundary Condition

- +Y

- Outlet

- Simple Boundary Condition

- Type - Outflow

- Simple Boundary Condition

- Slip

- Simple Boundary Condition

- Type - Slip

- Simple Boundary Condition

References

A Seifert and L.G. Pack. "Active Flow Separation Control on Wall-Mounted Hump at High Reynolds Numbers". AIAA Journal. 40(7). 2002.

NASA Langley Research Center Turbulence Modeling Resource web page. http://turbmodels.larc.nasa.gov/nasahump_val.html. Accessed June 2015.