Nastran

Nastran-specific checks used to calculate element quality for 2D and 3D elements.

Additional element checks not listed here are not part of the solver’s normal set of checks, and therefore use HyperMesh check methods.

2D and 3D Element Checks

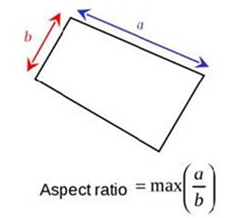

- Aspect Ratio

- Ratio of the longest edge of an element to its shortest edge.

Figure 1.

- Interior Angles

- Maximum and minimum values are evaluated independently for triangles and quadrilaterals.

- Jacobian

- Deviation of an element from its ideal or "perfect" shape, such as a triangle’s deviation from equilateral. The Jacobian value ranges from 0.0 to 1.0, where 1.0 represents a perfectly shaped element. The determinant of the Jacobian relates the local stretching of the parametric space which is required to fit it onto the global coordinate space.

- Skew

- HyperWorks creates lines between the midpoints of opposite sides of the element, then measures the angles between these lines. The angle with the greatest deviation from the ideal value is used to determine skew.

- Taper

- HyperWorks finds the taper of quadrilateral elements by treating each node as the corner of a triangle, using one of the quad’s diagonals as the triangle’s third leg. The areas of each of these four "virtual" triangles are compared to one half of the total area of the quadrilateral element to produce a ratio; the largest of these ratios is then compared to the tolerance value. A value of 1.0 is a perfect quadrilateral, and higher numbers denote greater taper.

- Warpage

- First, HyperWorks constructs a plane based on the mean

of the quad’s four points. This means that the corner points of a warped

quad are alternately H units above and below the constructed plane. This

value is then used along with the length of the element’s diagonals in

the following equation:Where WC is the Warping Coefficient, H is the "height" or distance of the nodes from the constructed plane, and D1 and D2 are the lengths of the diagonals. Thus, a perfect quad has a WC of zero.

3D Element Only Checks

- Vol. Aspect Ratio

- HyperWorks evaluates Tetrahedral elements by finding the longest edge length and dividing it by the shortest height, measured from a node to its opposing face. Other 3D elements, such as hex elements, are evaluated based on the ratio of their longest edge to their shortest edge.

- Warpage

- HyperWorks evaluates warpage on solid element faces by dividing the quad face into two trias along its diagonal, and measuring the cosine of the angle between the trias’ normals. This value will be 1.0 for a face where all nodes lie on the same plane.