LAW25 (Tsai-WU and CRASURV)

LAW25 is the most commonly used composite material in Radioss. It can be used with shell and solid elements. The two formulations available in LAW25 are the Tsai-Wu and CRASURV formulations.

Elastic Phase

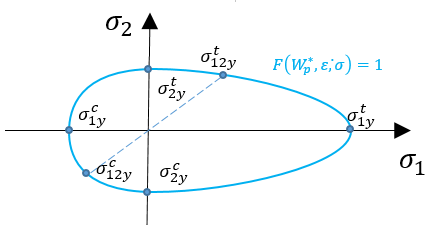

Tsai-Wu Yield Criteria for Iform=0 and =1

- Iform=0: Tsai-Wu

- Iform=1: CRASURV

- Tensile/compression tests

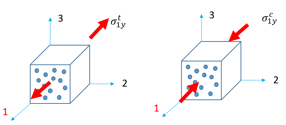

Longitudinal tensile/compression tests (in direction 1 which is fiber direction):

- Iform = 0: Tsai-Wu

- Iform = 1: CRASURV

- Here,

-

In tension:

In compression:

Here

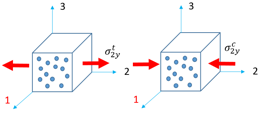

Transverse tensile/compression tests (in direction 2)

- Iform = 0: Tsai-Wu

- Iform = 1: CRASURV

- Here,

-

In tension:

In compression:

Here

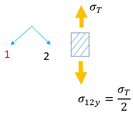

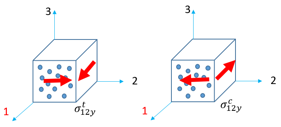

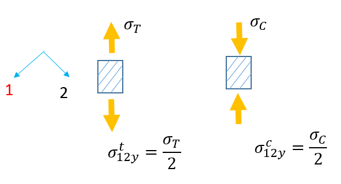

- Shear tests

Shear in plane 1-2

- Iform = 0: Tsai-Wu

- Iform = 1: CRASURV

- and can result from the sample tests:

-

- Here,

- Interaction coefficients

- Iform = 0: Tsai-Wu

- Iform = 1: CRASURV

- The default reduction factor, , is typically used.

- Here,

- Iform = 0: Tsai-Wu

- Iform = 1: CRASURV

- With

- Here

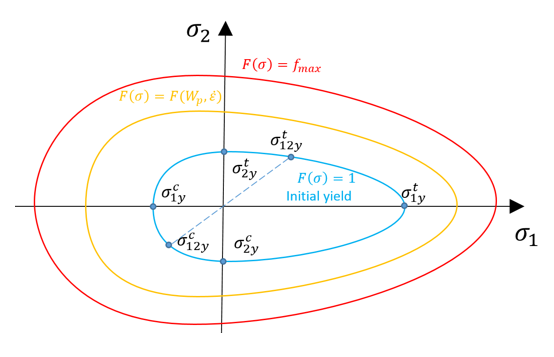

- Material in elastic phase, if

- Material in nonlinear phase, if

-

- The yield stress limit is in range of 1 and

- Material in elastic phase, if

In LAW25 (Tsai-Wu and CRASURV) damage is a function of the total strain and the maximum damage factor.

- If the total strain is between , the material begins to soften, but this damage is reversible. Once , then the damage is irreversible and if , then stress in material is reduced to 0.

- Damage could be in elastic phase or in plastic phase. It depends on which phase and are defined in.

- Element deletion is controlled by Ioff. Select a different Ioff option to control the criteria of element deletion. For additional information, refer to Ioff in LAW25 in the Reference Guide.