Hourglass Formulations

Under-integrated elements are very familiar in crash worthiness. In these elements, a reduced number of integration points are used to decrease the computation time. This simplification generates zero energy deformation modes, called hourglass modes.

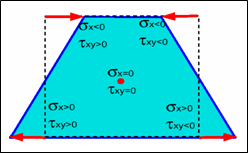

Figure 1. Zero Energy Mode Generation for a Reduced Integrated Shell

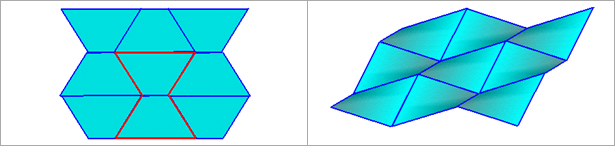

Figure 2. In-plane and Out-of-plane Hourglass Modes

- Perturbation or penalty method: Hourglass control by application of anti-hourglass forces to maintain deformation stability of the element (historical method).

- Physical stabilization method: Hourglass control by the correction of internal energy in an analytical way.

- Type 1 (Default option): Only in-plane modes are corrected, valid for shells and solids.

- Type 2: Old formulation no longer recommended.

- Type 3: Plasticity is taken into account in the computation of anti-hourglass forces; in-plane and out-of-plane hourglass modes are corrected; available only for shells.

- Type 4: Like Type 1 with additional higher order terms in the computation of anti-hourglass forces and with out-of-plane hourglass mode correction; available only for shells.

- QEPH shell

- HEPH solid

- HSEPH solid-shell

The choice of hourglass formulation plays an essential role on the quality of results. If the mesh is fine enough, the physical stabilization method can be used. Otherwise, Type 3 and Type 4 formulations are recommended for shell meshes. When the material undergoes elastic-plastic behavior, the Type 3 formulation is much more efficient. The hourglass coefficient, hm and hf are recommended to be set to 0.1; however, the default value, hf=0.01 can be used for hr.