Mold

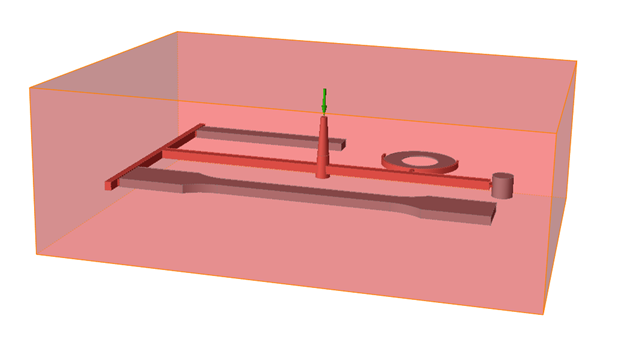

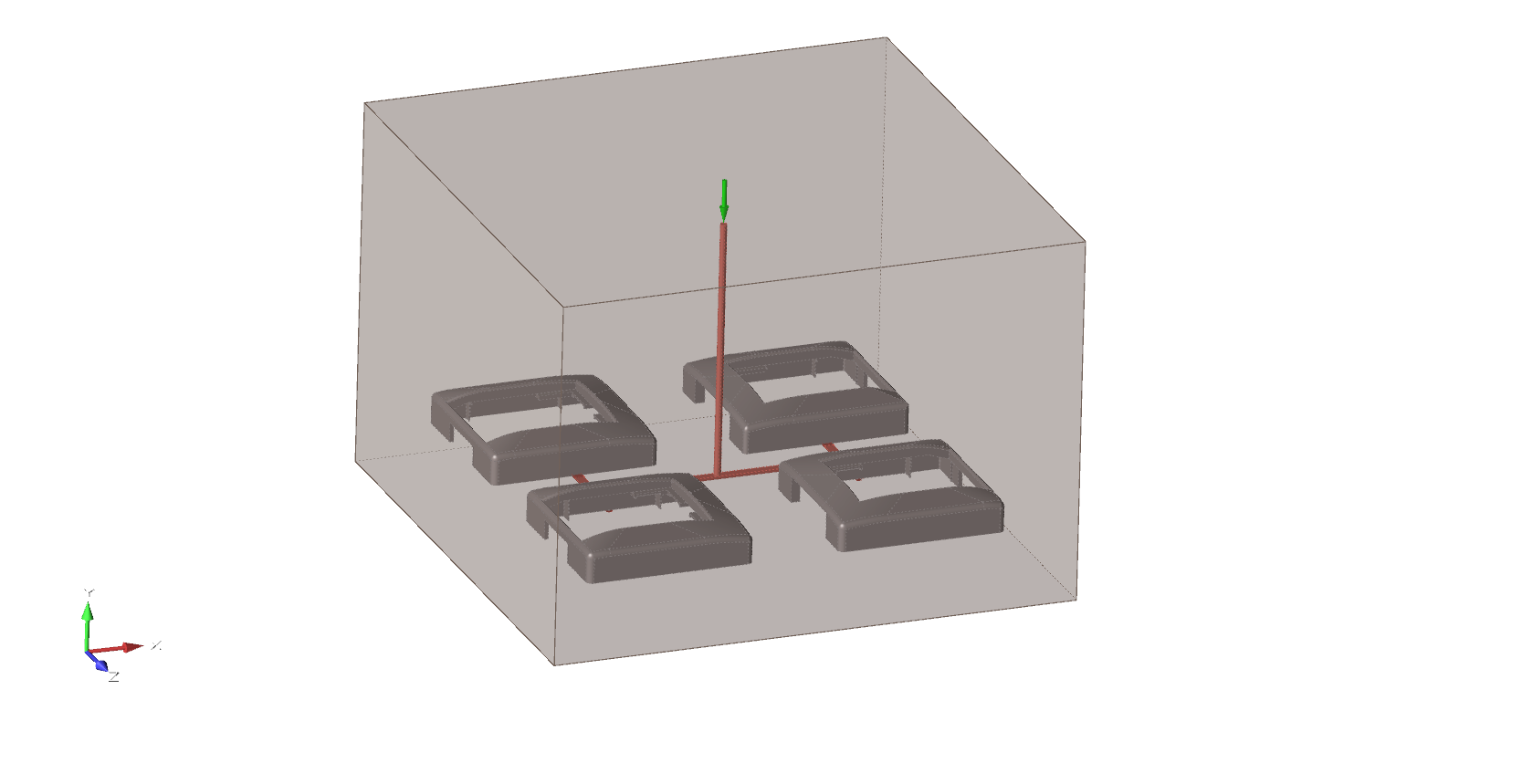

A mold is the bounding box for the tooling components.

Add/Edit Mold

Create and edit a mold that is by default 30% larger than the bounding box of the tooling.

Microdialog Options

Define the material, temperature, and position of the mold.

| Option | Description |

|---|---|

| Select the Material Viewer to examine the material's Thermal, Rhealogical,

Mechanical, PVT and Fiber properties. Note: You can use the Material Viewer to edit an

existing material, save it with a new name, and access it from the My Materials

tab.

|

|

|

Select a material from the list. |

|

Enter the temperature of the material. |

|

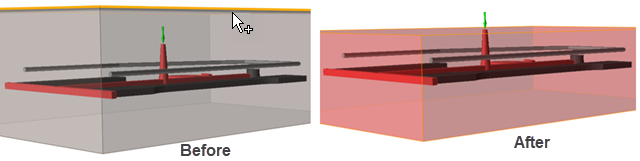

Select the Move Mold Face tool so that the injection point is outside of the

mold, then select the mold face that you want to move. |

|

Select the Move tool to position the mold. |

|

Select the Reset button to apply the default parameters to the mold. |

|

Select the Deselet button to remove the mold designation. |

|

Enter the dimensions of the mold in the X-, Y- or Z- direction. |

| X-Axis, Y-Axis or Z-Axis | Select the opening direction for the mold on the X-, Y- or Z-axis. |