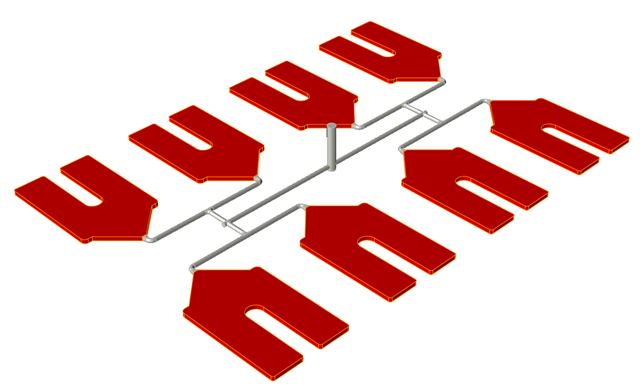

Part Cavity

Designate the part cavities in your model geometry, automatically define part cavities and a runner system, and reorient part cavites.

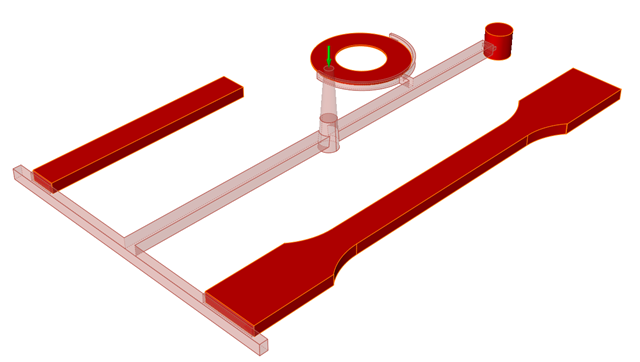

Automatically Detect Cavities

Click the inlet surface to automatically select and define the mold part cavities and running system.

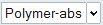

Designate a Cavity

Select the molding parts and define the material, polymer, and temperature.

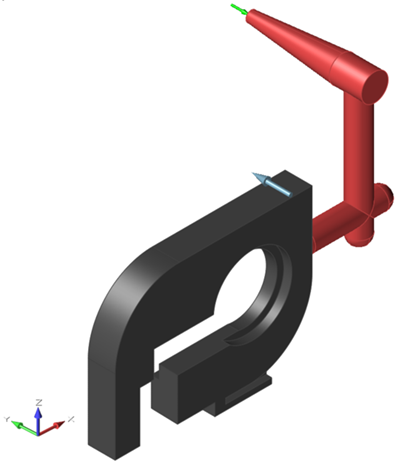

Reorient a Cavity

Reorient a part cavity to a mold opening.

The Reorient Cavity tool lets you change the orientation of your part cavity in respect to the mold opening direction.