seam-quad (angled)

Creates one quad row under a certain angle. The angle is measured between the quad row and the perpendicular projection from the free edge to the opposite shell link. In addition, a certain pure quad element pattern is created around the seam elements, shown here in red. These elements normally get imprinted into the shell links. The exact geometry of the seam can be influenced by the angle value.

Figure 1.

Quad Realization Options

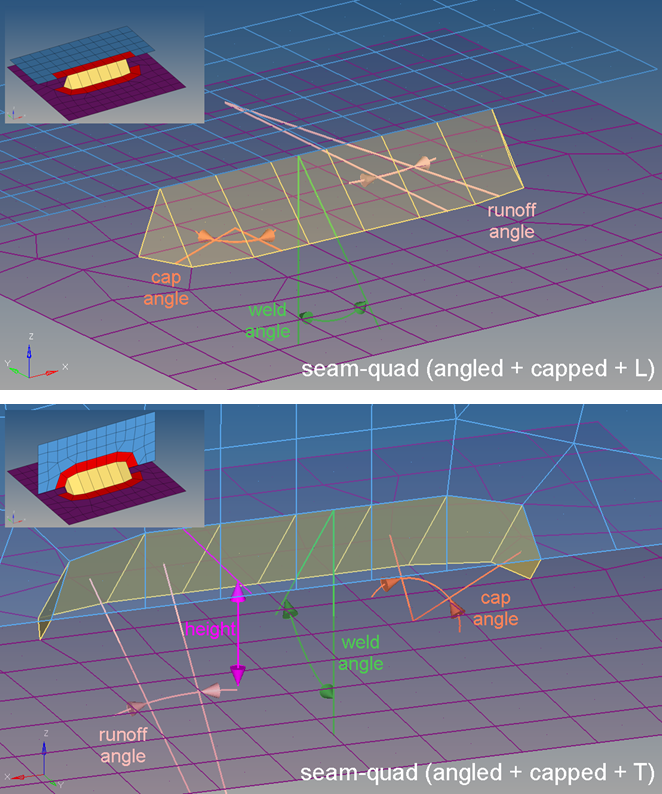

Figure 2.

| Option | Action |

|---|---|

| weld angle | Define the distance between the normal projection and the

quad direction. Principally it is allowed to define weld angles between 0.0 and 90.0. If the value is set to 0.0 an internal thickness-based calculation is used. If the value is set to 0.0 and no thickness is defined the connector will fail. If the angle is created in the wrong direction, the seam can be reverted by enabling the reverse direction checkbox and performing a rerealization. |

| cap angle | Depending on the seam-quad type, the cap angle is measured

differently.

Cap angles are created by default. Clear this checkbox to remove cap angles and runoff angles. Cap angles

between 0.0 and 45.0 are permitted, but be aware that larger

values can lead to bad elements. The recommended value is

10.0 or smaller. Cap angles between 45.0 and 90.0 are

permitted, but be aware that smaller values lead to bad

elements. The recommended value is 75.0 and

higher.

Note: Only available for seam-quad (angled +

capped + L) and seam-quad (angled + capped +

T).

|

| runoff angle | Depending on the seam-quad type, the runoff angle is measured

differently.

|

| height | Define the distance between the projection point and the

start-point of the angled quads. Note: Only available for

T-seams.

The height needs to be chosen in an extent to

bridge the gap between the links. Also, the height strongly

influences the quad length, especially in cases of very large

weld angles. |