hexa (seam tie)

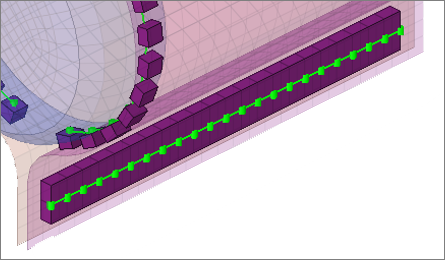

Creates hexa elements between shell and/or solid elements in order to connect them using a tie contact definition. The hexa element nodes will project and touch the shell and/or solid element faces. During the realization, a default tie contact and referencing main and secondary sets are created; unless defined differently, the hexas are assigned a default property and material, and are organized into a component with the same name base as the property.

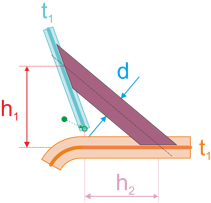

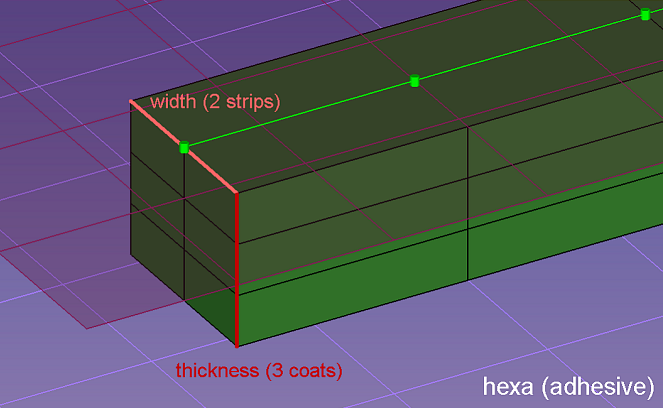

Figure 1.

Hexa Realization Options

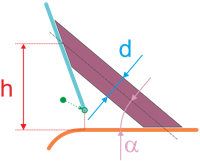

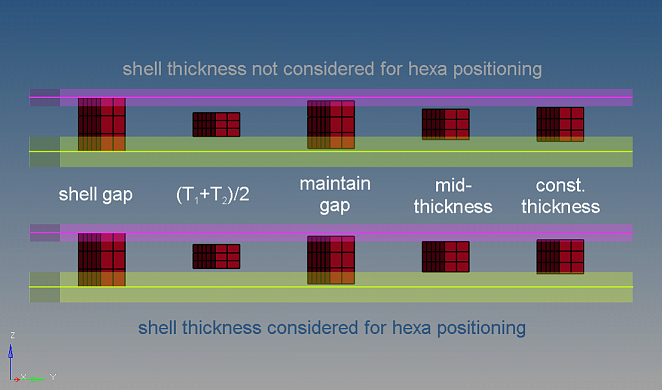

Figure 2.

| Option | Action |

|---|---|

| width | Define the width of the continuous hexa weld in the direction

perpendicular to the seam direction. Note: Only available for

hexa (adhesive) and hexa (RBE2-RBE3).

|

| strips | Define the number of hexa elements required along the width. |

| coats | Defines the number of hexa elements required along the thickness. |

| thickness |

Select a method for defining the thickness of a hexa

weld.

Note:

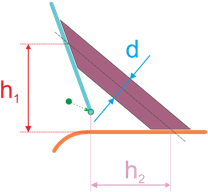

Figure 3. |

| thickness dependent / angle, D and H / H1, H2 and D | Hexa (tapered T) enables you to create tapered seam hexas for

T-connections. Select a method to define how hexas are

positioned and located, and assign appropriate values to any

corresponding inputs.

|

| discontinuity | By default, the length and pattern of a hexa weld is defined

by test points along the seam connector. To ignore the

predefined test points, and define a specific element length,

weld length, and break length to realize the connector with,

select the discontinuity checkbox. With this option, a hexa

adhesive seam with alternating weld pieces and gaps is created.

When discontinuity is enabled, you must define the

following inputs:

Note: Only available for

hexa (adhesive) realizations.

|

| hexa position to edge | Select a location to create the hexa from the edge.

Note: Only

available for hexa (adhesive) and hexa

(RBE2-RBE3).

|

| edge details |

In many cases, the connector position is not very

precise. To create the requested result, an automatic edge snapping can be enabled.

In the first step the connector snaps to, for example, the closest free edge, and

then from there the projection and FE creation starts. Select how many element rows

away from the free edge to snap the connector to for L and T connections.

|