General

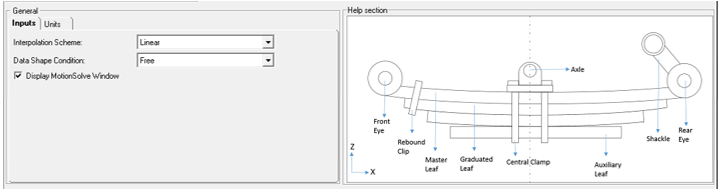

The General option in the tree browser provides basic details and displays the entire model in the Help section. It is necessary for all the property files.

Figure 1. General Panel Section

Inputs

- Interpolation Scheme

- Defines the type of interpolation the you need for the leaf profile.

- Data Shape Condition

- The Leaf Spring Builder builds leaf springs from two different kinds of

profile inputs or shape conditions.

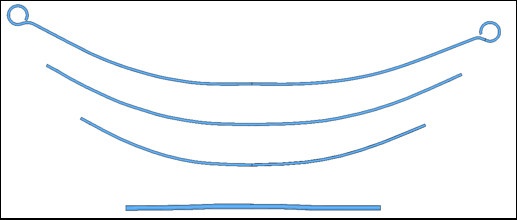

- Free Shape Condition: In Free Shape

condition, you can generate a design, loaded in the leaf spring

pack. In other words, you have a bolted leaf pack and intend to push

it with design load. The leaf pack will be generated with a bolt

(fixed joint) and a design load. The input profiles for this option

will be the profiles as extracted from a bolted leaf stack. A Free

Shape condition is when the leaves’ shapes are extracted from an

assembled, but unloaded leaf pack. Note: The leaf pack is in an assembled condition but is NOT installed in a vehicle.

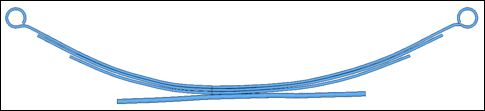

Figure 2. Spring in Free Position - Pre-Assembly: In Pre-assembly, you have

individual leaf profiles for each leaf in its free shape. These

individual leaf profiles can be bolted together first, followed by

applying a certain design load in a sequential simulation. The

following image shows that all the leaves are separated and should

be bolted together. Hence, if you have a free shape of each leaf,

you can use this option and enter the data accordingly.

Figure 3. Spring in Pre-assembly Position

- Free Shape Condition: In Free Shape

condition, you can generate a design, loaded in the leaf spring

pack. In other words, you have a bolted leaf pack and intend to push

it with design load. The leaf pack will be generated with a bolt

(fixed joint) and a design load. The input profiles for this option

will be the profiles as extracted from a bolted leaf stack. A Free

Shape condition is when the leaves’ shapes are extracted from an

assembled, but unloaded leaf pack.

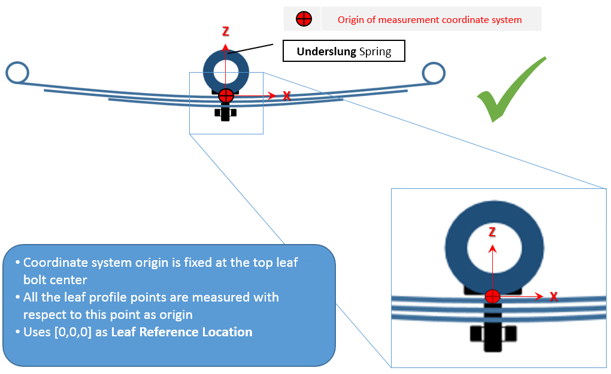

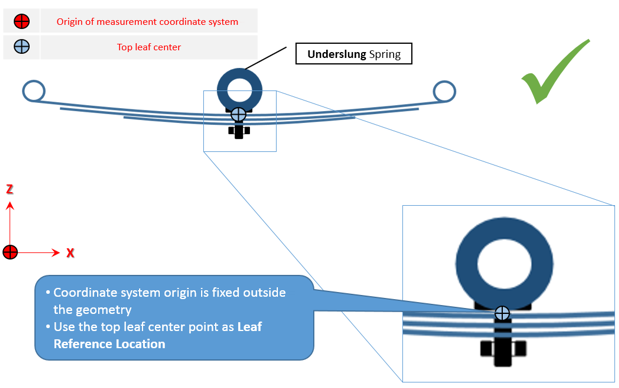

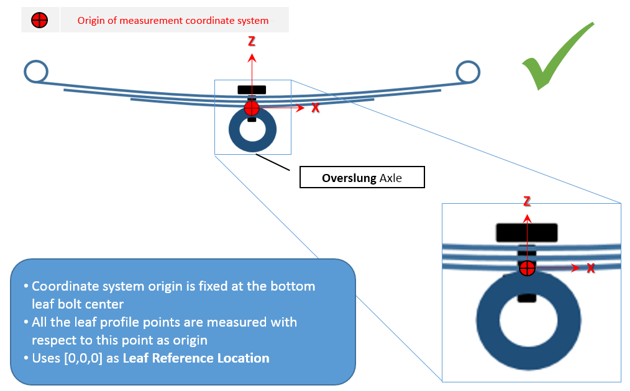

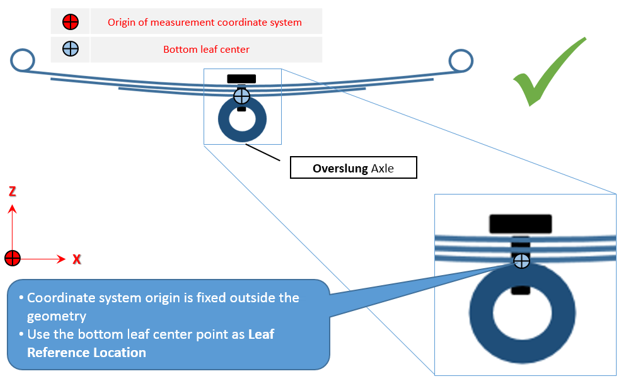

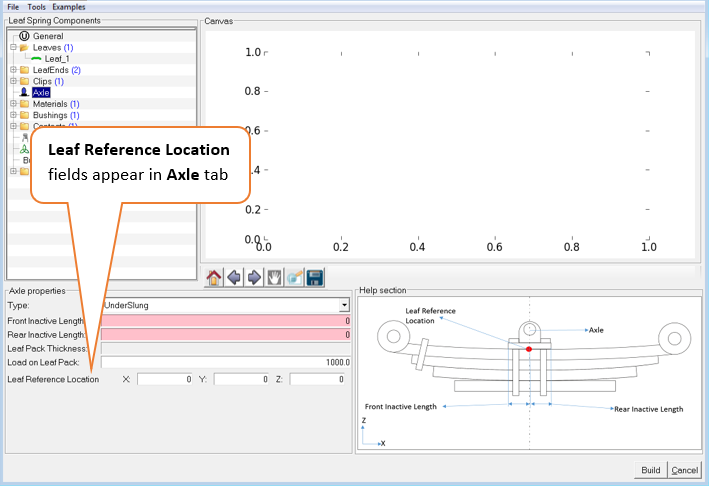

Leaf Spring Shape Measurements

The Leaf Spring Builder creates MotionView MDL leaf-spring models which are only as good as the leaf shapes you input. Therefore it is important to accurately measure the leaf shapes in the required coordinate system. The coordinate system, its origin and orientation, needs to follow certain rules to be useful in creating a leaf-spring from the Leaf Spring Builder.- Measuring a Leaf Spring in Free Shape

- In Free Shape, the leaves are already assembled into a pack, but not

installed in the vehicle. Hence, all of the leaves together form a

single unit. In this condition, the measurements need to be made in a

consistent coordinate system. Also, it is necessary to input a correct

Leaf Reference Location under the Axle tab. The Leaf Reference Marker

will be created at this location.

Figure 4. Leaf Reference Location in Axle Component Properties

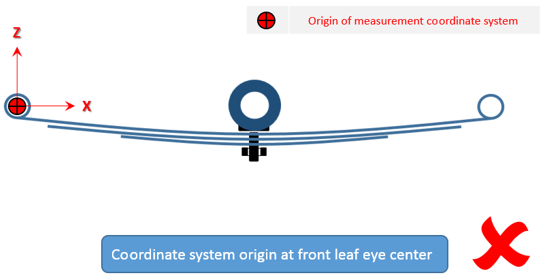

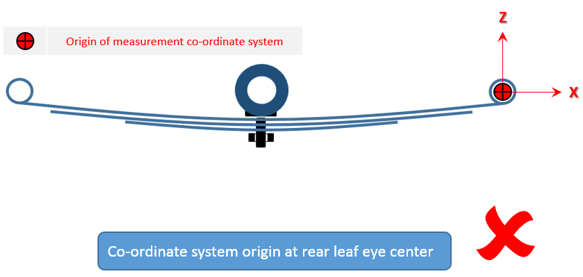

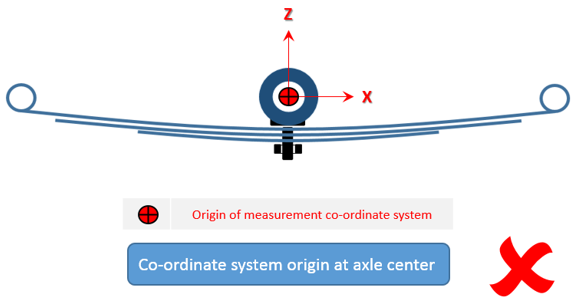

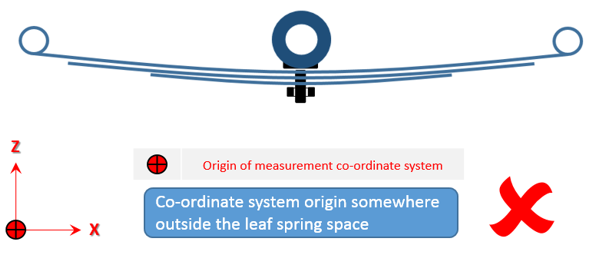

- Unacceptable Selections:

-

Figure 9. Unacceptable selection-1

Figure 10. Unacceptable selection-2

Figure 11. Unacceptable selection-3

Figure 12. Unacceptable selection-4

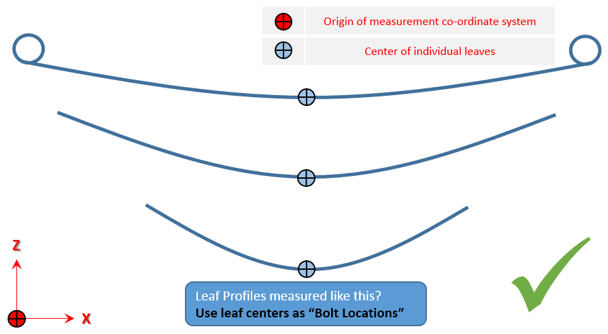

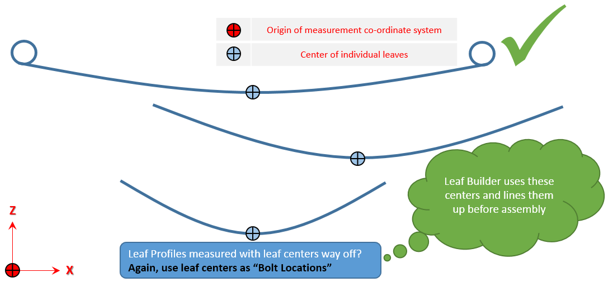

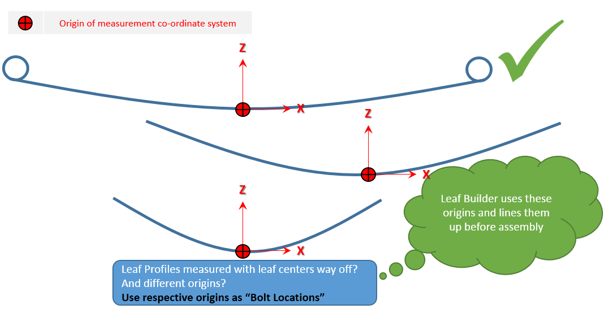

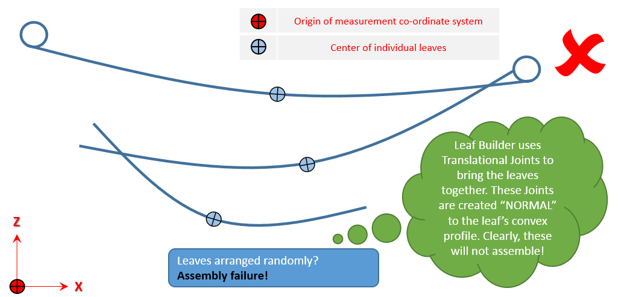

Measuring a Leaf Spring in Pre-Assembly Shape

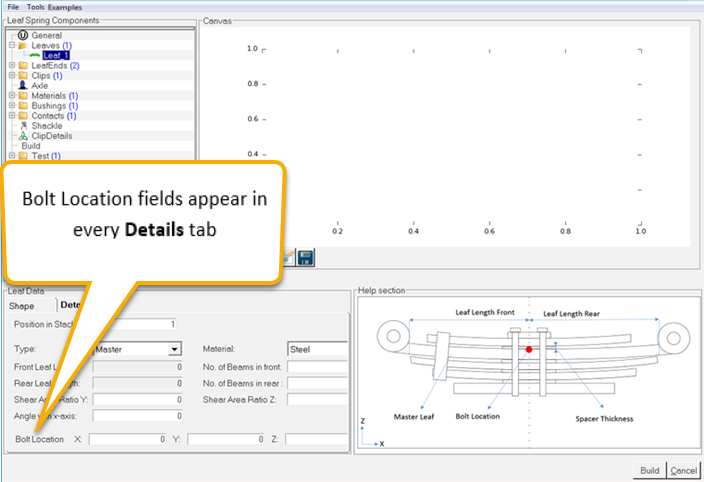

Leaves in the Pre-Assembly Shape condition are measured as independent entities. A common coordinate system needs to be chosen for all the leaves. The Leaf Builder takes an additional input called Bolt Location in the Pre-Assembly Shape condition, which is used to line up the leaves along a common vertical axis before they are bolted together in a MotionSolve simulation to create the assembled leaf pack.

Figure 13. Bolt Location in Leaf Details

- Acceptable Selections:

- The bolt hole axis of each leaf must be parallel to every other leaf and

he z-axis. The vertical locations of each leaf will be offset by

MotionSolve during assembly, such that

there is no contact between leaves.

Figure 14. Acceptable Selection for Pre-Assembly-1

Figure 15. Acceptable Selection for Pre-Assembly-2

Figure 16. Acceptable Selection for Pre-Assembly-3 - Unacceptable Selection:

-

Figure 17. Unacceptable Selection for Pre-Assembly-1

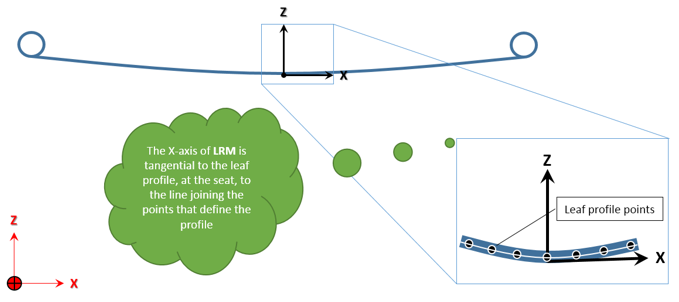

Leaf Reference Marker

The Leaf Reference Marker (henceforth referred to as LRM in this section) is the coordinate system in which all the points of the leaf profiles are created in MotionView. To move/orient a leaf spring, you can simply move and/or reorient the LRM.

Figure 18. Leaf Reference Marker Location

- Free Shape: Leaf Reference Location as input by the user, top leaf center for underslung spring and bottom leaf center for overslung spring.

- Pre-Assembly Shape: Top leaf bolt location for underslung spring and bottom leaf bolt location for overslung spring.

The Leaf Builder uses the Leaf Reference Marker-origin (location) as the point where the Axle is attached.

General Inputs for Leaf Property File (*lpf)

$---------------------------------------GENERAL_INPUTS

[GENERAL_INPUTS]

CURVEFITTING = 'LINEAR'

DIRECTORY = 'C:\USERS\NG\DESKTOP'

DISPMSOLVEWINDOW = 'TRUE'

NOOFLEAVES = 4.0

NOOFREBOUNDCLIP = 0.0

OUTPUTFILELABEL = 'TEST_LEAF_1'

SHAPECONDITION = 'DESIGN'

| Attributes | Type | Valid Value | Required |

|---|---|---|---|

| Directory | String | Directory path | Yes |

| noOfLeaves | Integer | 1, 2, 3... | Yes |

| curveFitting | String | Linear Quadratic Cubic |

Yes |

| noOfReboundclip | Integer | 1, 2, 3... If there are none, then “ZERO” has to be mentioned. |

Yes |

| shapeCondition | String | 'FREE' 'PRE_ASSEMBLY' |

Yes |

| outputFileLabel | String | File_label | Yes |

| frictionSwitch | String | 'On', 'OFF' | Optional |

| dispMsolveWindow | String | 'TRUE, 'FALSE'' | Yes |

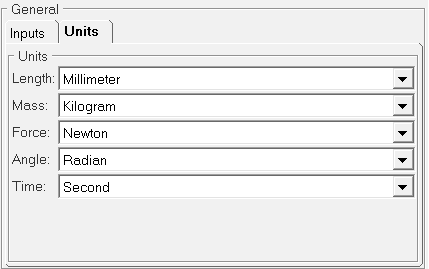

Units

Figure 19. General - Units Tab

Units for Leaf Property File (*lpf)

$---------------------------------------------------------UNITS

[UNITS]

(BASE)

{LENGTH FORCE ANGLE MASS TIME}

MILLIMETER NEWTON RADIAN KILOGRAM SECOND