Thermal Effects (Combined) Analysis

Evaluate squeak and rattle issues when exposed to thermal loading.

A typical challenge faced in the automotive industry is how does the vehicle interior perform under driving conditions while the vehicle has been parked in the sun for many hours?

To answer this question, vibration loads responses (Dynamics) need to be superposed to the temperature effect on parts (Thermal Expansion – Static), gaps are reduced for example. In this workflow, the user will evaluate the squeak and rattle issues in a dynamic condition where the vehicle, in this case, a parked under sunlight with a spike in internal temperature (Static loadcase). Later the car is driven, which is exposed to Dynamic Loading. Below is the illustration of the Driving Vehicle exposed to the Thermal Effects (Combined Loading) workflow..png) Figure 1.

Figure 1. - Prepare the FE model for analyzing Squeak and Rattle issues.

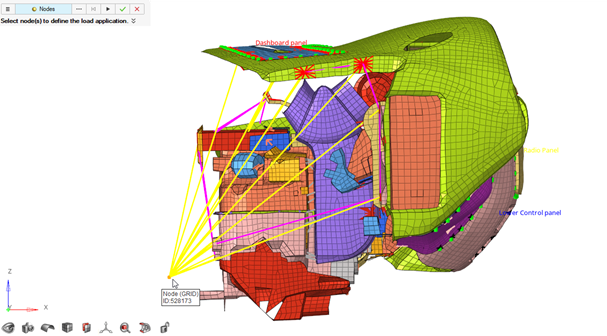

- Apply a static load of amplitude -5.55 to the certain node(s) on Lower Control Panel component. This simulates a touch point scenario.

- Run analysis and post-process the results.

- Use a fresh model and prepare the model analysis setup. For this workflow, refer the following sections from Detailed Risk and Root Cause Analysis:

- Import a model with Dynamic Event loadcase. For this workflow, you can use the model with solver deck created in the Detailed Risk and Root Cause Analysis usecase along with the Dynamic Loadcase.

Choose the workflow according to your need and refer to sections mentioned above for the procedures.

Files Required

Files required to complete the usecase.

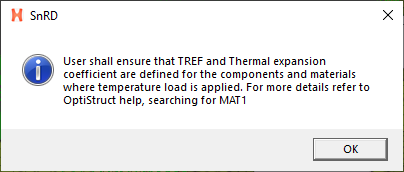

Step 5: Thermal Event Definition and Export

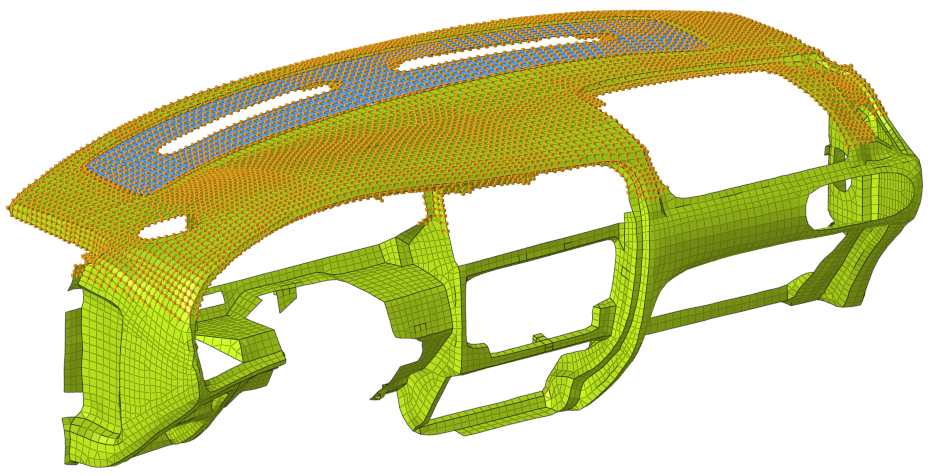

Apply thermal loading on the top surface of the IP Substrate and Dashboard Panel.

Define Thermal Loadcase

Below are the steps to create thermal loadcase.

Define Constraint

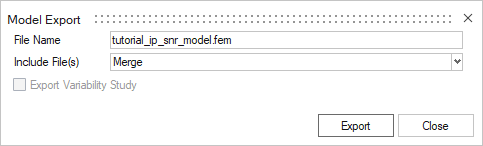

Export OptiStruct Solver File

.FEM solver deck

to solve on OptiStruct solver. Once done, two output files are generated:

.H3D and .PCH. These files will be used in

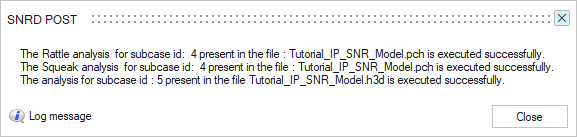

the Post Processing of results.Step 6: Post Processing and Results Evaluation

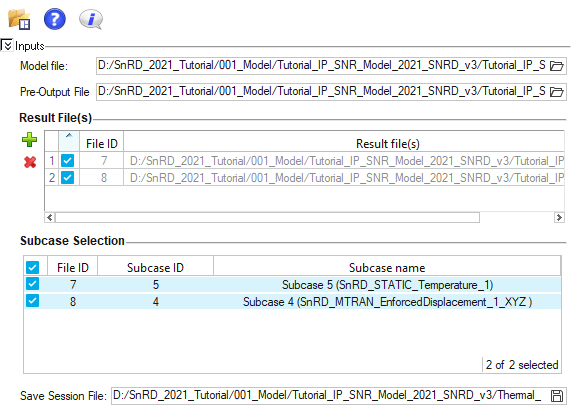

Import model and results file

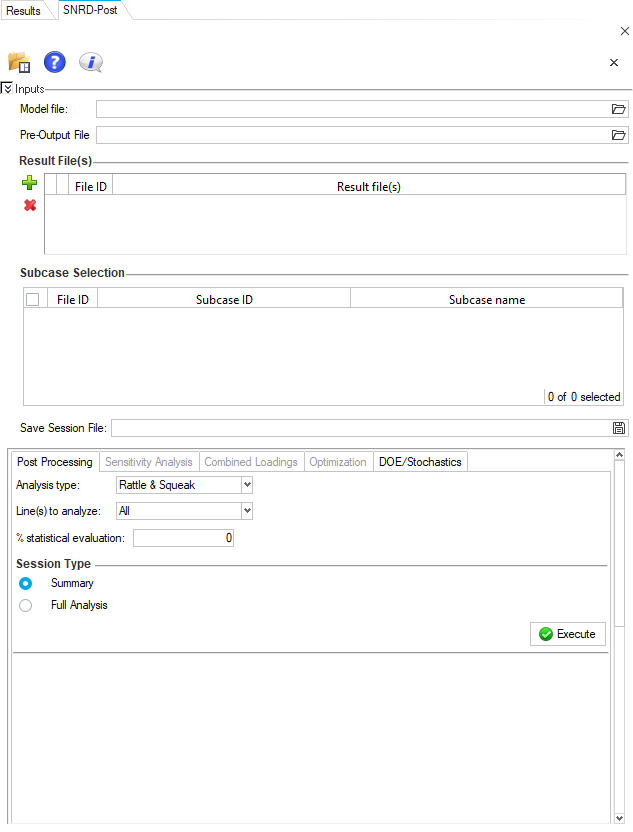

Use the SnRD Post to post process the results.

Launch HyperWorks X, switch to HyperView client. Select . Preferences window will appear. Select Squeak & Rattle and click Load. This creates SnRD menu in the HyperView window.

Post Process

Perform Full Analysis to understand the Squeak and Rattle risks in the model.

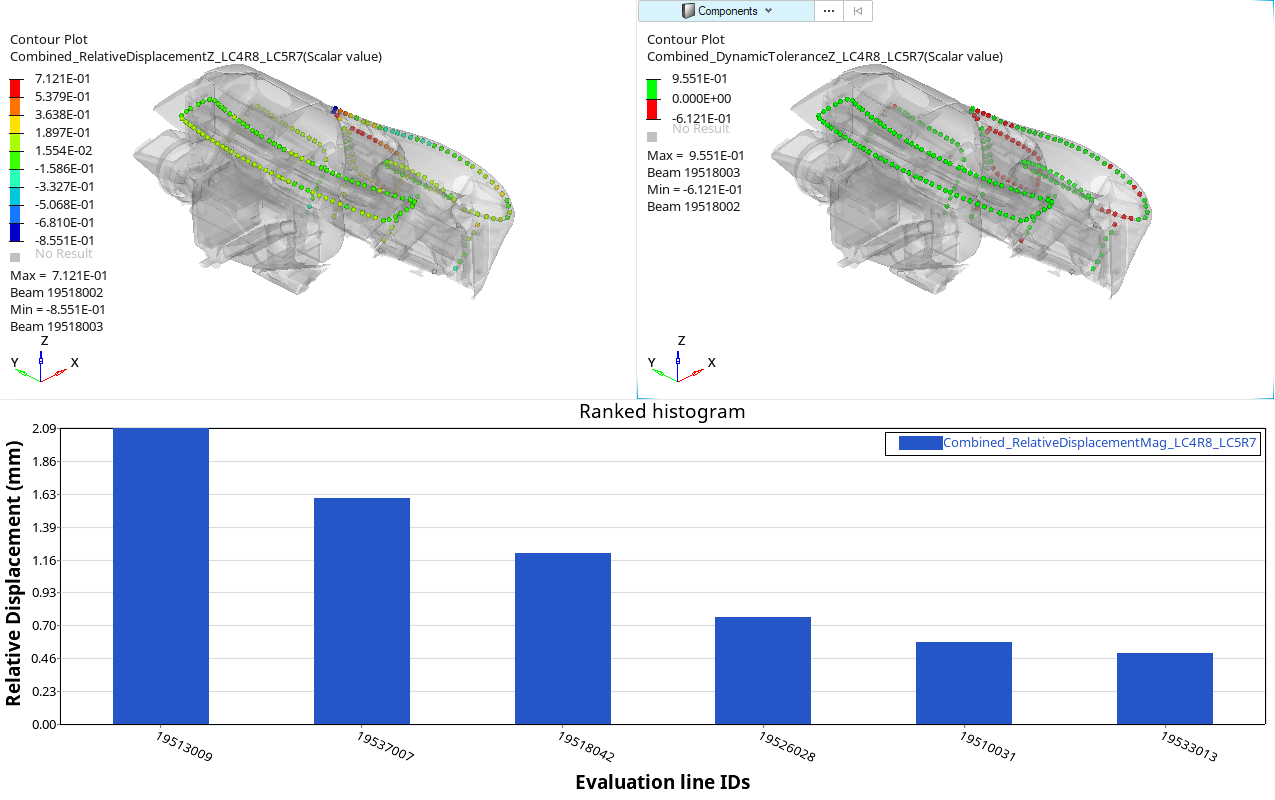

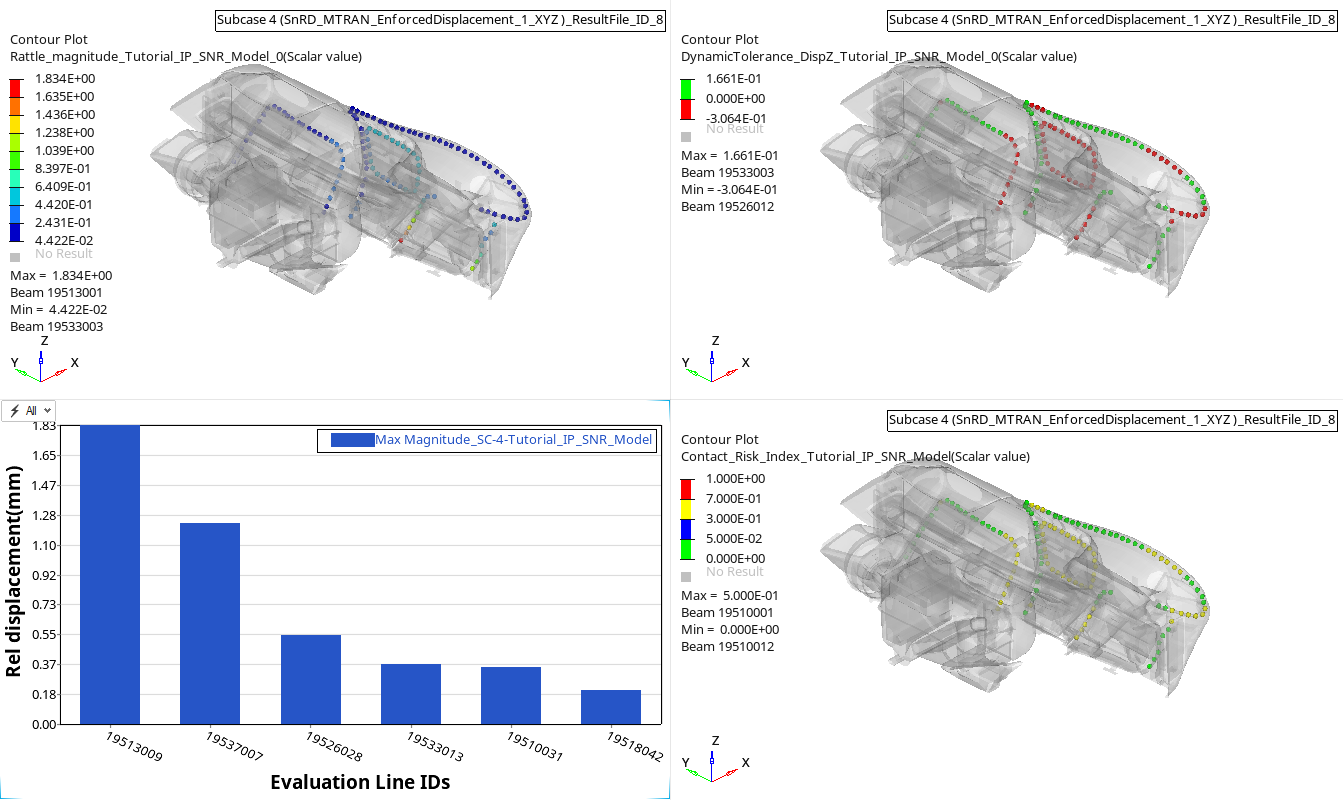

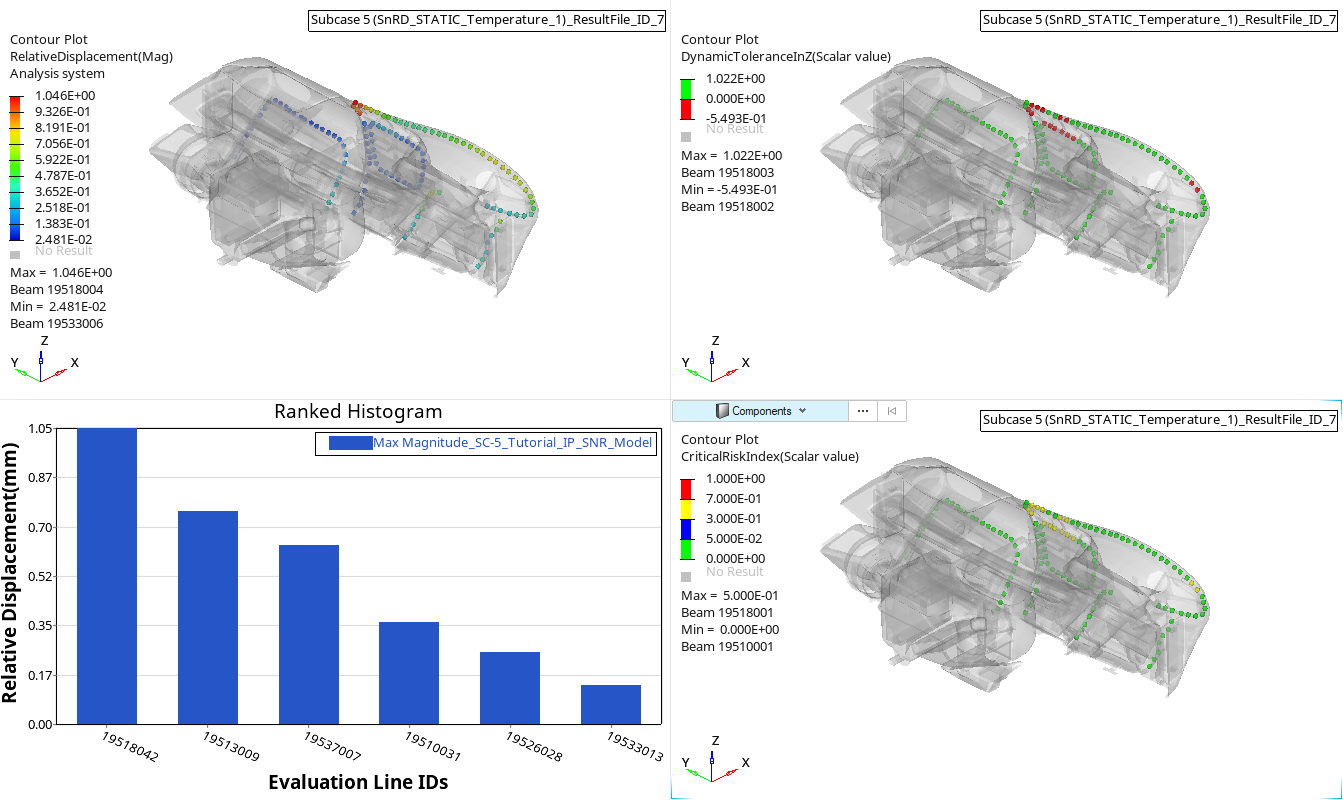

Figure 14. Rattle Summary Dynamic

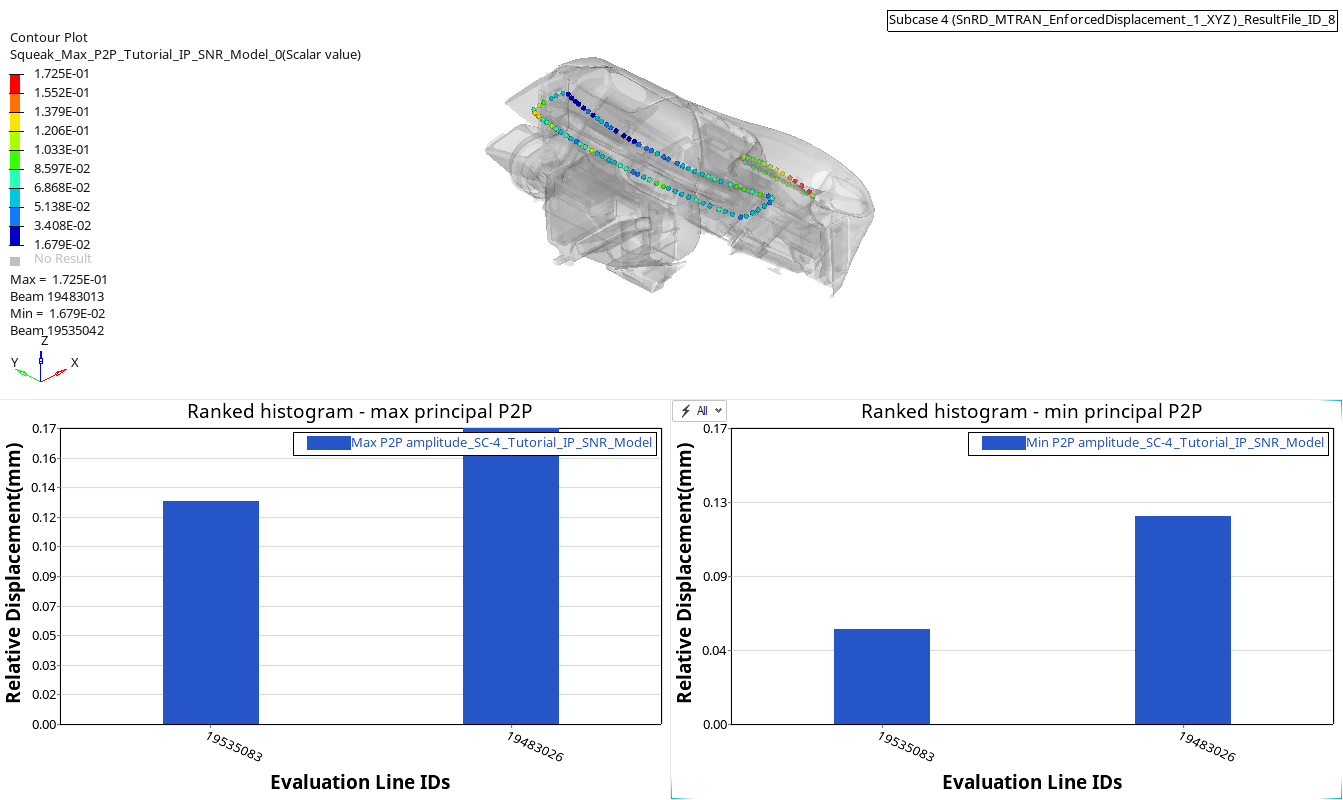

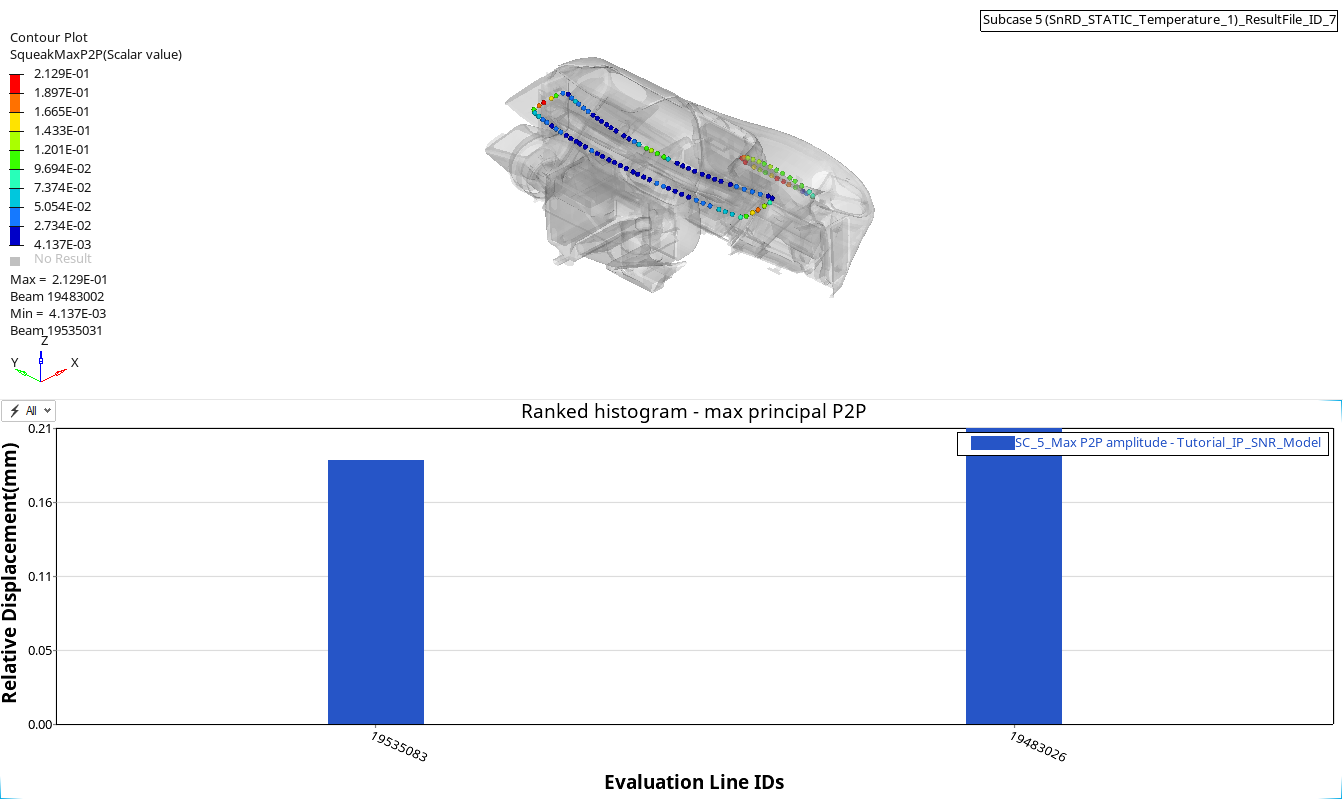

Figure 14. Rattle Summary Dynamic Figure 15. Squeak Summary Dynamic

Figure 15. Squeak Summary Dynamic Figure 16. Rattle Summary Thermal

Figure 16. Rattle Summary Thermal Figure 17. Squeak Summary Thermal

Figure 17. Squeak Summary ThermalCombined Loading

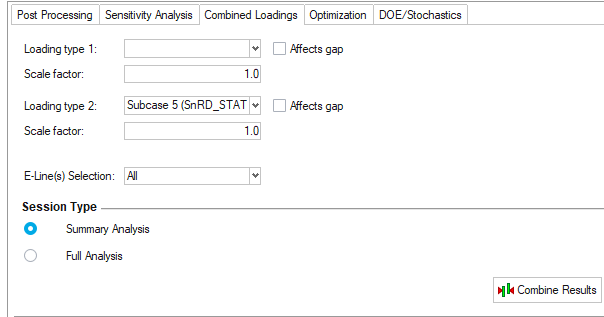

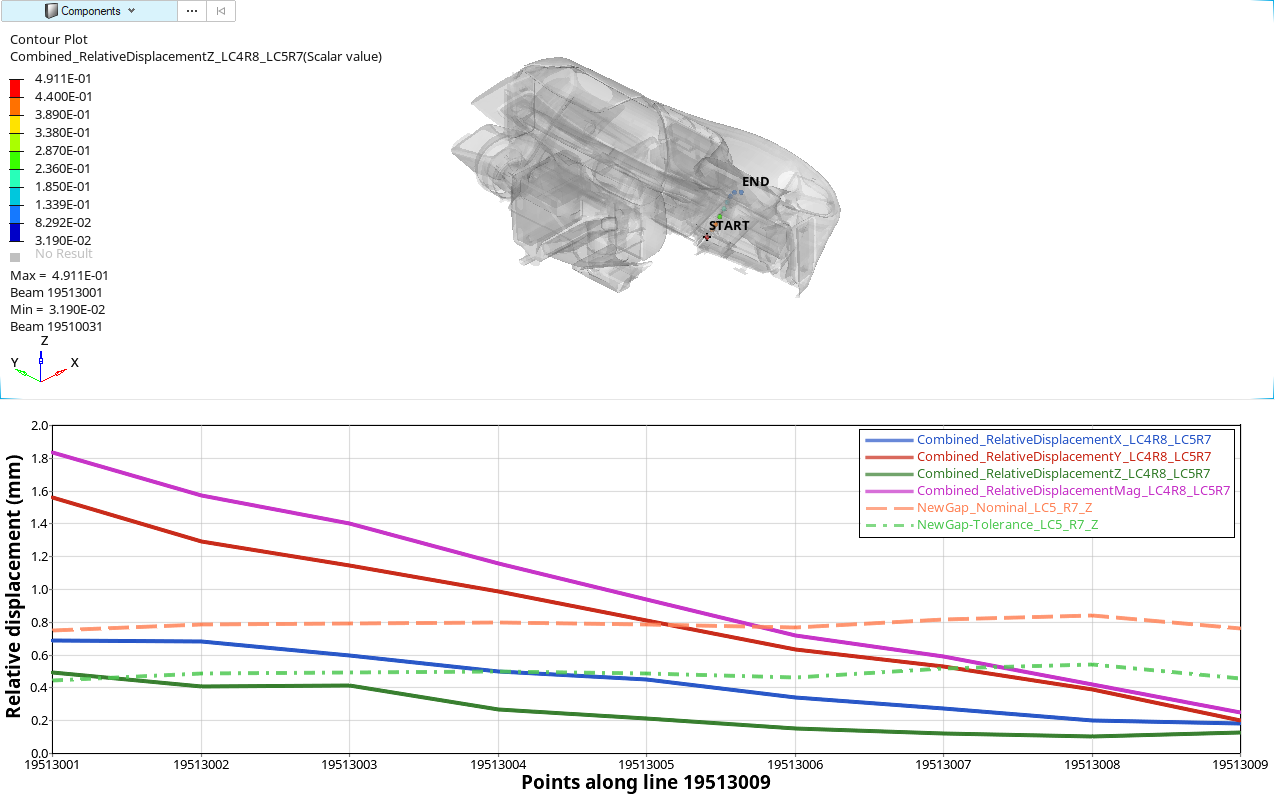

Perform a Combined Loading study to understand the thermal effects on the squeak and rattle issues under Dynamic Loading condition.

.

. in the

in the