BatchMesher Midmesh Generation Rules

Midmesh generation is also supported from within BatchMesher.

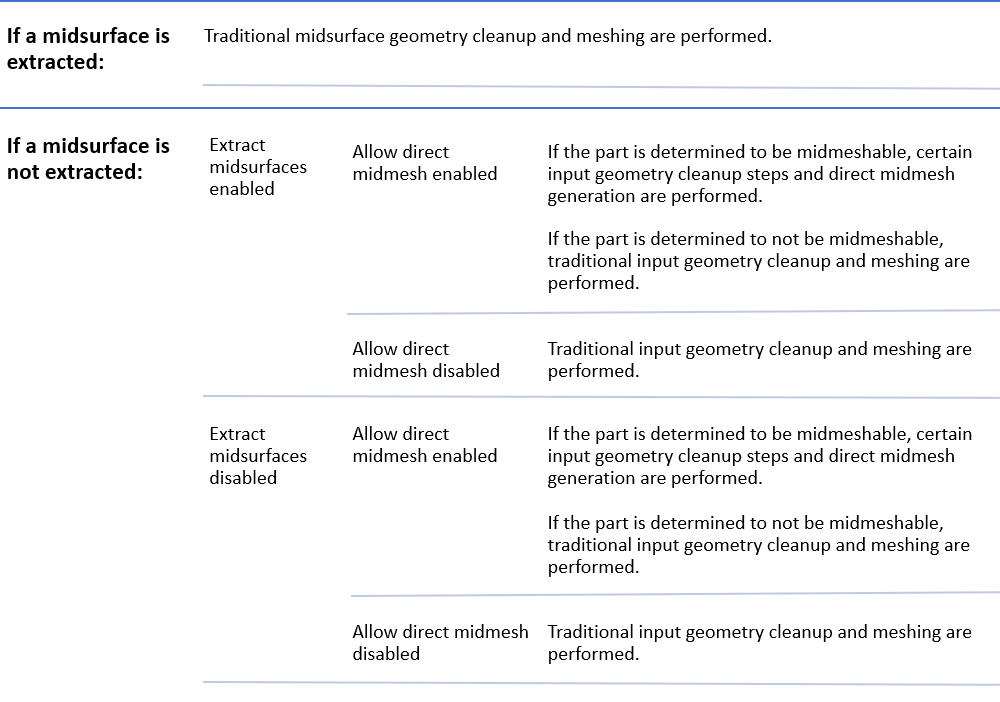

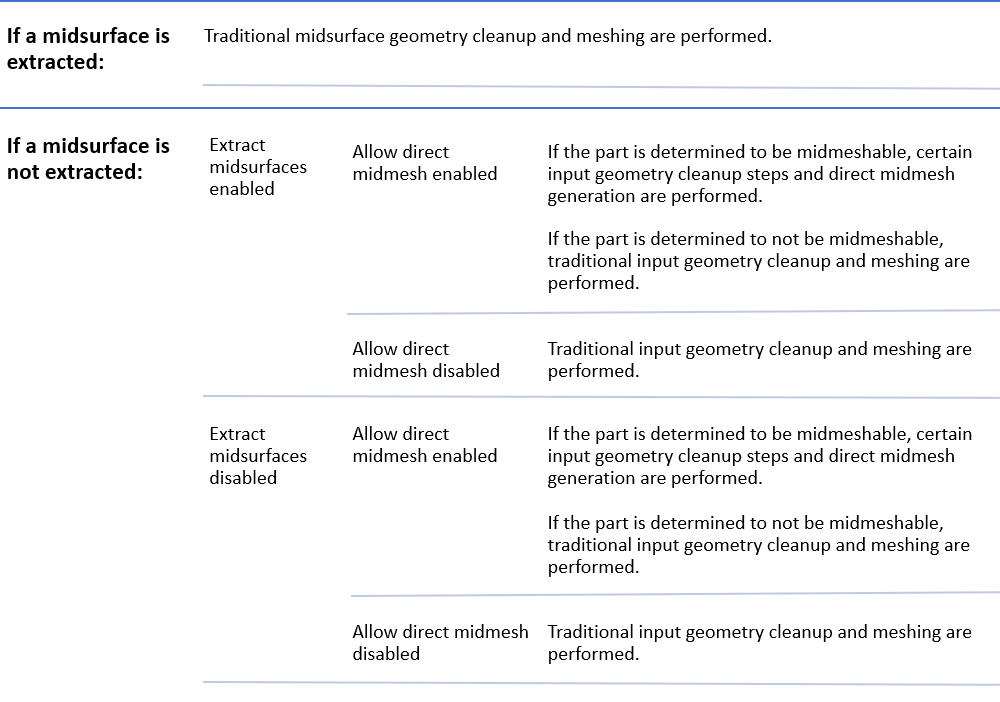

Figure 1.

View new features for HyperWorks 2021.2.

Learn the basics and discover the workspace.

Discover HyperWorks functionality with interactive tutorials.

Create, open, import, and save models.

Set up sessions and create report templates.

Solver interfaces supported in HyperWorks.

A solver interface is made up of a template and a FE-input reader.

Create, organize and manage parts and subsystems.

Create and edit 2D parametric sketch geometry.

Create, edit, and cleanup geometry.

Different types of mesh you can create in HyperWorks.

Edit the Parameter and Criteria files and define mesh controls using the Mesh Controls Browser.

1D mesh that allows accurate testing of connectors, such as bolts, and similar rod-like or bar-like objects that can be modeled as a simple line for FEA purposes.

A surface mesh or "shell mesh" represents model parts that are relatively two-dimensional, such as sheet metal or a hollow plastic cowl or case.

Use the General 2D Mesh tool to create 2D meshing with various algorithms.

Use the BatchMesher tool to perform geometry feature recognition, cleanup and automatic meshing in batch mode for given CAD files.

Use the CFD 2D Mesh tool to generate hybrid grids containing hexa/penta/tetra elements in the boundary layer and tetra elements in the core or fare field.

Use the Panel Mesh tool to generate and edit mapped panel mesh.

Use the Rigid Body Mesh tool to create a quick mesh to represent the topology of a rigid object.

Automatically generate a mesh at the midplane location, directly from the input geometry (components, elements, solids or surfaces), without first creating a midsurface.

Use the Midmesh: Automatic tool to automatically generate a mesh at the midplane location, directly from the input geometry (components, elements, solids or surfaces), without first creating a midsurface. This saves significant time over the traditional midsurface-based approach.

Use the Midmesh: Repair/Fill tool to repair midmesh by attempting to fix topological problems (holes/gaps/cracks, intersections, slivers, overlaps) in the mesh and remesh the face, or create a mesh within a closed topology loop, attempting to keep tangency.

Use the Midmesh: Create Midedge tool to create a midedge.

Use the Midmesh: Edit Topology tool to edit midmesh topology.

Use the Midmesh: Align tool to align the midmesh.

Use the Midmesh: Inspect tool to view/fix nodes deviating from the middle of the geometry, such as Nodes off middle, Nodes off solid edges, Nodes out of solid, Edges off solid edges, and Element centers off middle. The fix corrects the mesh to the mid by node movement or splitting elements.

Midmesh generation is also supported from within BatchMesher.

Use the Feature Edges tool to create and edit mesh controls on an edge.

The Rebuild tool streamlines the process of remeshing existing meshes to generate a new mesh with good quality and flow. The rebuild mesh functionality utilizes the same parameter and criteria files used by BatchMesher to define the quality criteria and relevant mesh parameters. This algorithm saves significant time over the traditional automesh and quality correction approach.

Adaptive wrap meshing is a useful utility to get a clean, water tight shell mesh out of 2D mesh containing several intersecting parts and small gaps which do not need to be modeled.

EM Lattice meshing is a method to create an axis-parallel mesh for 2D and 1D geometry input.

Shrink wrap meshing is a method to create a simplified mesh of a complex model when high-precision models are not necessary, as is the case for powertrain components during crash analysis.

Create facets out of a scanned data set or node cloud data.

Bulkheads are design enablers that provide localized performance benefits for multiple design attributes such as NVH, Safety, and so on. When their position and thickness are precisely designed, bulkheads can reduce mass and increase performance as they eliminate up-gauging of entire part(s). Typically, bulkheads are welded on one side and bonded with a structural adhesive on the other side and can be incorporated even during the late stages of the product design cycle.

Doublers are design enablers that provide localized performance benefits for multiple design attributes such as NVH, Safety, and so on. When their position and thickness are precisely designed, doublers can reduce mass and increase performance as they eliminate up-gauging of entire part(s). Typically, doublers are typically welded on one side and bonded with structural adhesive on the other side and can be incorporated even during the late stages of the product design cycle.

Volume mesh or "solid meshing" uses three-dimensional elements to represent fully 3D objects, such as solid parts or sheets of material that have enough thickness and surface variety that solid meshing makes more sense than 2D shell meshing.

Create and edit 0D/1D entities and edit 2D elements.

Rapidly change the shape of the FE mesh without severely sacrificing the mesh quality.

Create connections between parts of your model.

HyperMesh composites modeling.

Validate the model built before running solver analysis.

Tools used for crash and safety analysis.

Airbag solutions offer airbag folder utilities and exports a resulting airbag in a Radioss deck.

Workflow to support topology optimization model build and setup.

Multi-disciplinary design exploration and optimization tools.

Essential utility tools developed using HyperWorks-Tcl.

Import an aeroelastic finite element model with Nastran Bulk Data format.

Framework to plug certification methods to assess margin of safety from the model and result information.

Streamline the creation of properties and 1D stiffener mesh using the info read from Marine CAD tools.

Create evaluation lines, evaluate them, and optimize the interfaces to eliminate squeak and rattle issues.

A Packaged Solution Offering (PSO) that provides a flexible and customizable platform for building and analyzing geomechanical models.

Panels contains pre-processing and post-processing tools.

Results data can be post-processed using both HyperMesh and HyperView.

HyperGraph is a data analysis and plotting tool with interfaces to many CAE file formats.

MotionView is a general pre-processor for Multibody Dynamics.

MediaView plays video files, displays static images, tracks objects, and measures distances.

TextView math scripts reference vector data from HyperGraph windows to automate data processing and data summary.

TableView creates an Excel-like spreadsheet in HyperWorks.

Create and export Document and Presentation reports with one click and also define your own report structure.

Different types of mesh you can create in HyperWorks.

A surface mesh or "shell mesh" represents model parts that are relatively two-dimensional, such as sheet metal or a hollow plastic cowl or case.

Automatically generate a mesh at the midplane location, directly from the input geometry (components, elements, solids or surfaces), without first creating a midsurface.

Midmesh generation is also supported from within BatchMesher.

Midmesh generation is also supported from within BatchMesher.

(c) 2021. Altair Engineering Inc. All Rights Reserved.