Friction Correlations

The friction in the FlowSimulator element can be calculated by the given equation

where ![]() stands

for calculated friction based on user selected friction mode (Abauf, Swamee), friction

type (Fanning or Darcy) and Re (to determine whether it is in turbulent region, or in

laminar region);

stands

for calculated friction based on user selected friction mode (Abauf, Swamee), friction

type (Fanning or Darcy) and Re (to determine whether it is in turbulent region, or in

laminar region);

![]()

If ReDh < ReTurb, laminar friction calculations take place, otherwise, turbulent friction calculation routine is used.

| Nomenclature: | Subscripts: |

| f: friction | F: fanning |

| Re: Reynolds number | D: darcy |

| FMULT: friction multiplier | turb: turbulent flow |

| ε: sand grain roughness | lam: laminar flow |

| A: Cross sectional area | Abuaf: Abuaf friction relation |

| L+: Inlet station + 1/9 of 2nd station | Smooth: smooth surface |

| XMU: dynamic viscosity | Rough: rough surface |

| W: mass flow rate | SJ: Swamee-Jain approximation |

| X: station length | Dh: hydraulic diameter |

| L: equivalent diameter |

Laminar Friction

Calculates the friction coefficient for laminar flow in shaped ducts based on the references (Yunus A. Cengel, 2006) and (Bruce Munson, 2005).

Friction coefficient for hydrodynamically fully developed flow can be calculated as,

![]()

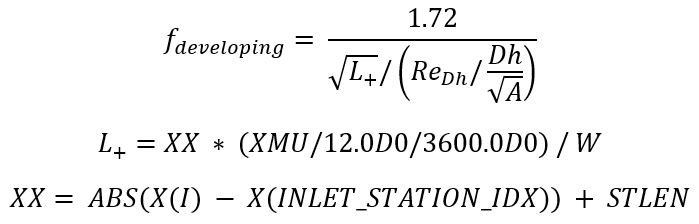

For Tube Element, Laminar Friction Inlets effects can be accounted. Friction coefficient for hydrodynamically developing flow with “Muzychka Yovanovich Laminar Inlet Effects” can be calculated as,

Friction coefficient for combination of developing flow and fully developed flow can be calculated as,

![]()

Darcy type friction then calculated as;

![]()

Fanning type friction then calculated as;

![]()

Turbulent Friction

Calculates the turbulent friction for smooth or rough walls.

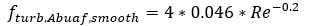

Abuaf Friction Relation

The Abuaf friction relation should generally be used for smooth walled tubes.

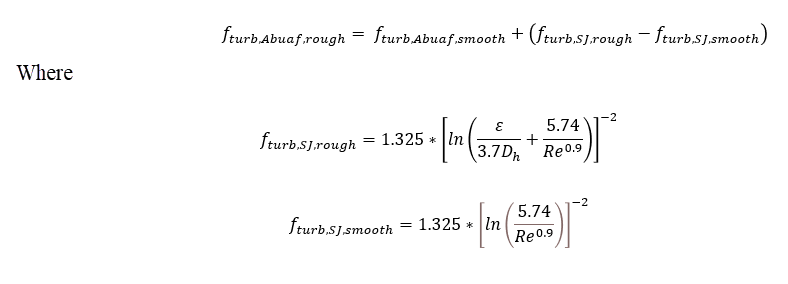

Flow Simulator allows users to an option use the Abuaf friction relation together with wall roughness. The following adjustment equation is used:

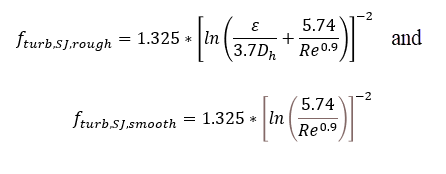

Swamee-Jain approximation of the Colebrook-White equation (Moody diagram)

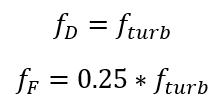

The Darcy and Fanning type frictions are calculated as:

User-specified friction factor

![]()

Roughness

| ε=5.863∗Ra, | Ra=Average Absolute Roughness |

| ε=3.100∗Rrms, | Rrms=Root Mean Square Roughness |

| ε=0.978∗Rzd, | Rzd=Peak to Valley Roughness |