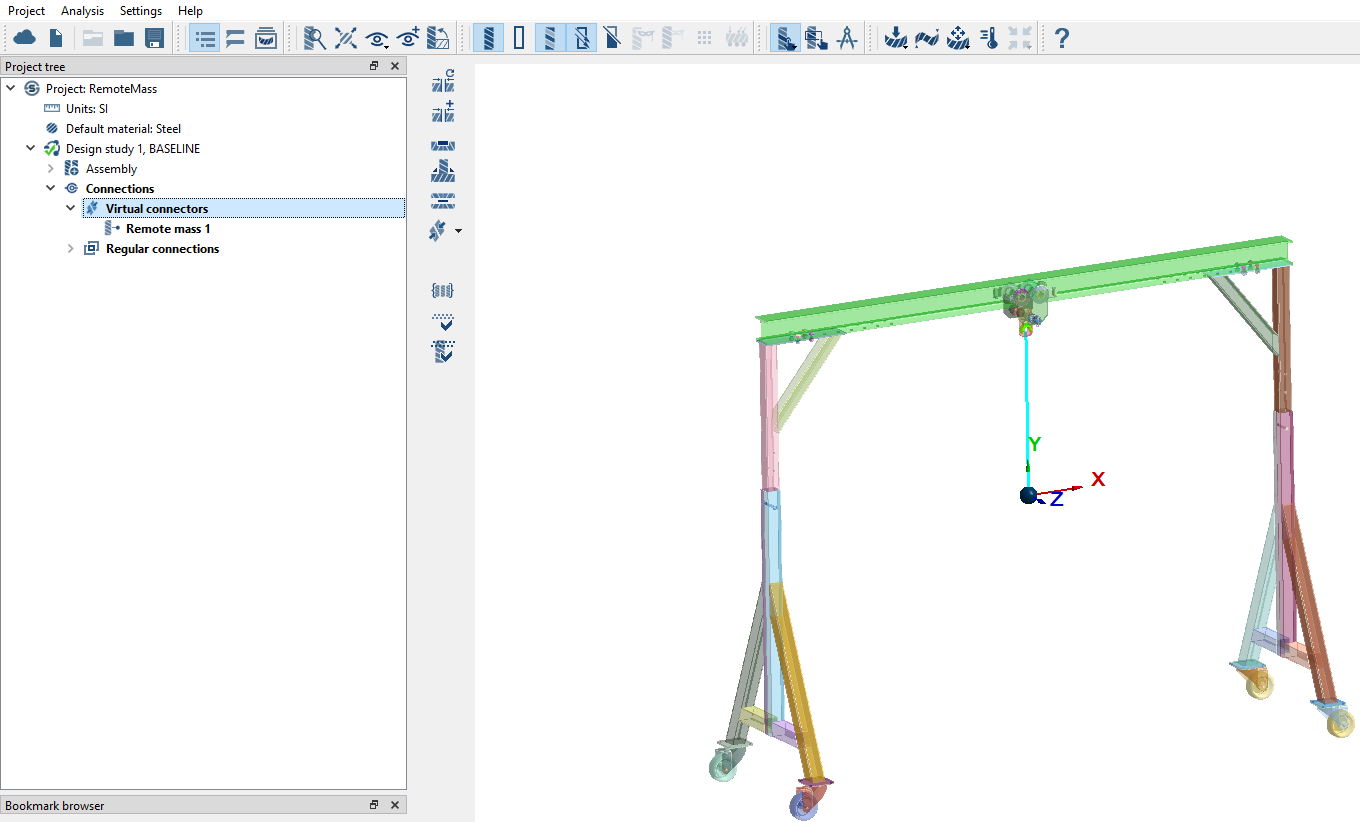

SS-T: 2050 Remote Mass

Create Remote Mass in SimSolid.

Purpose

- Create Remote Mass on a Gantry hoist.

Model Description

- RemoteMass.ssp

Figure 1.

- Material is set to Steel for all parts.

- Regular connections with 0.003mm gap and penetration tolerance.

Open Project

Open the SimSolid project file.

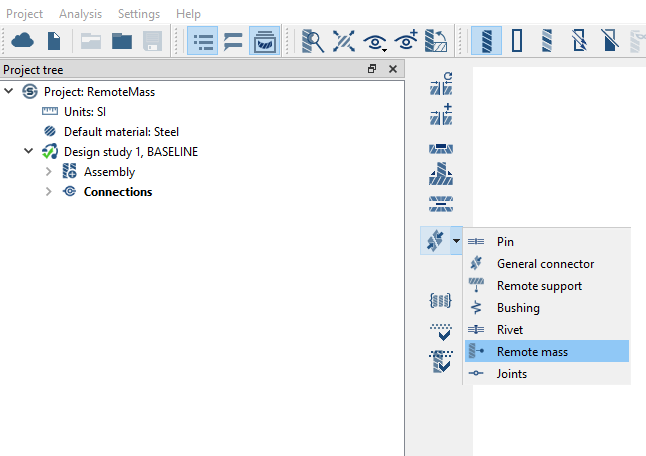

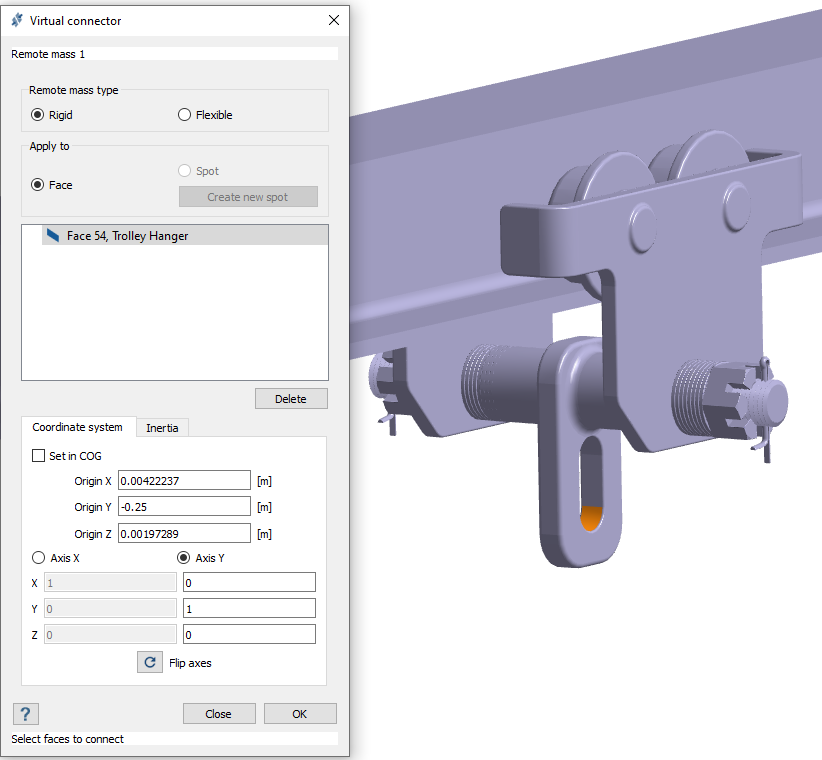

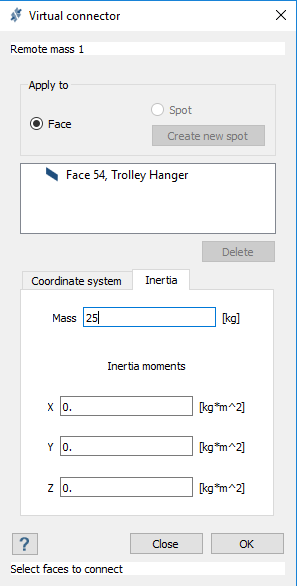

Create Remote Mass

Create remote mass on selected faces.

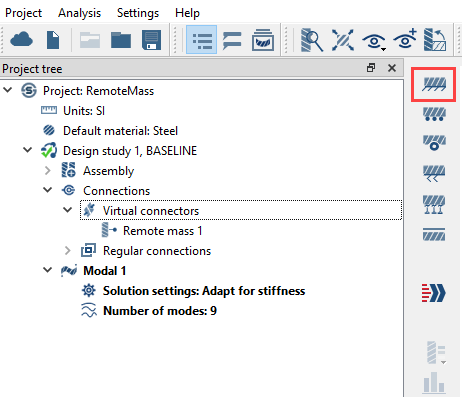

Create Modal Analysis

Create Immovable Supports

Create immovable supports

Run Analysis

Solve the analysis.

- In the Project Tree, open the Analysis Workbench.

-

Click

(Solve).

(Solve).

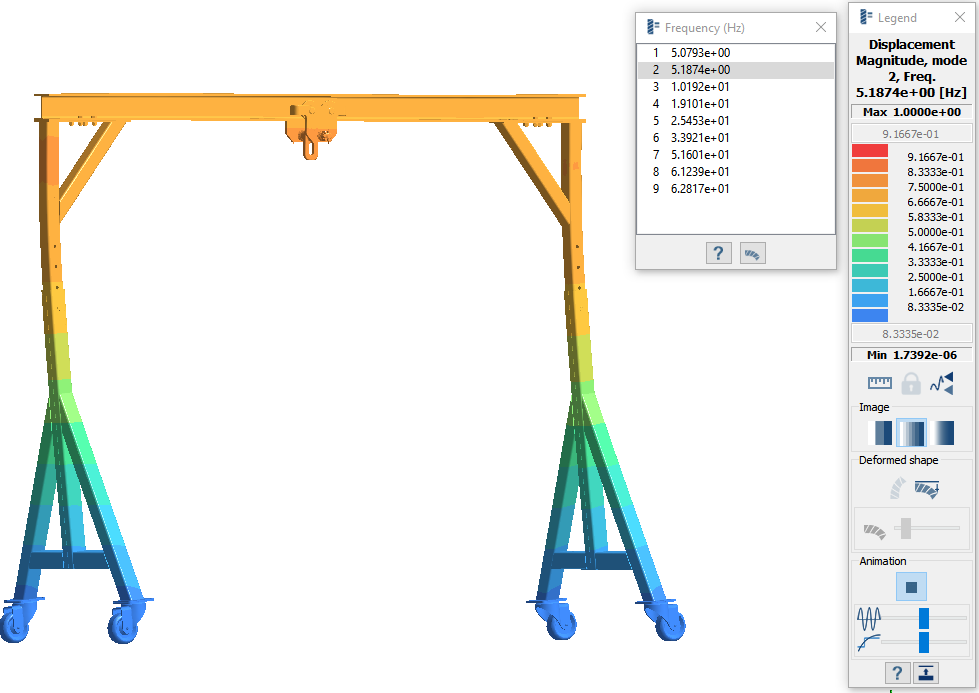

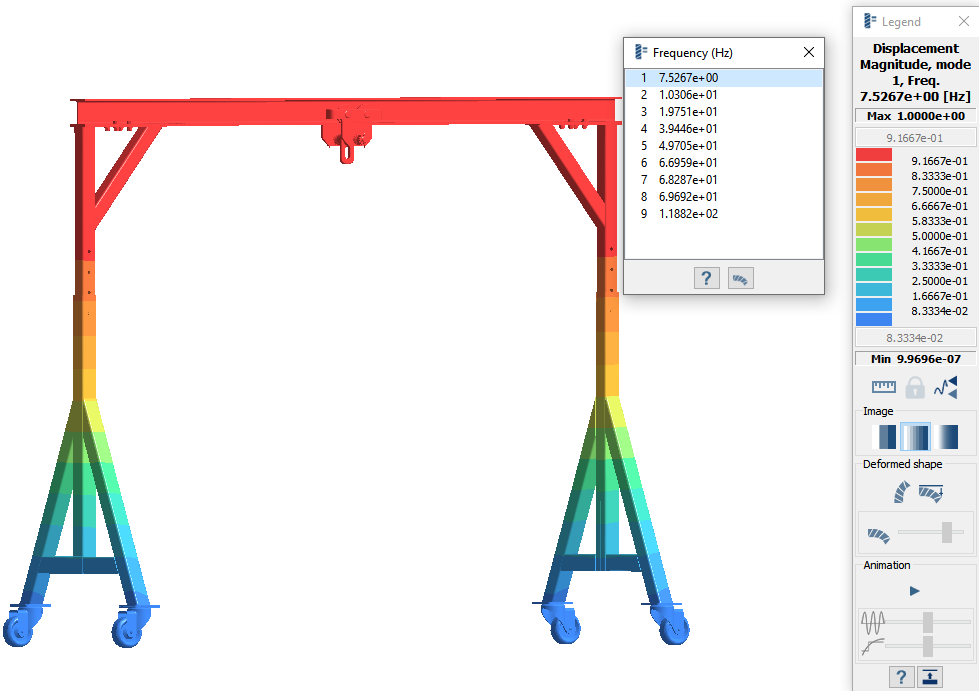

Review Results

Plot the displacement contour.

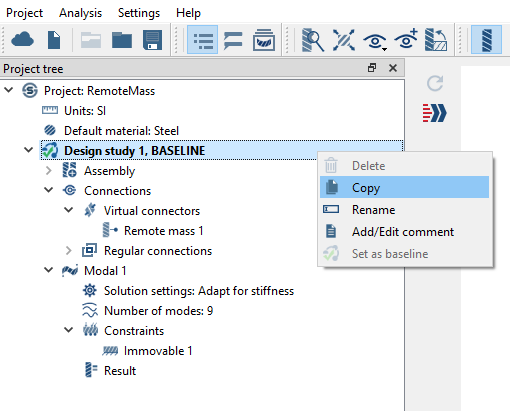

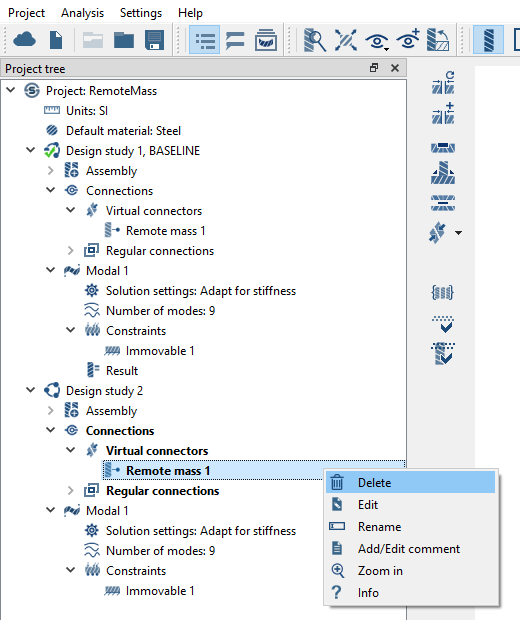

Compare Results With and Without Remote Mass

View displacement magnitude contour plot for both analyses and compare results.

supports_faces.png)