MV-1080: Create an Analysis Using MDL

In this tutorial, you will learn how to create an analysis definition and instantiate it in an MDL file.

- Analysis definitions use *DefineAnalysis(), while system definitions use *DefineSystem().

- Analysis can be instantiated under the top level Model only.

- Only one analysis can be active in the model at a given instance.

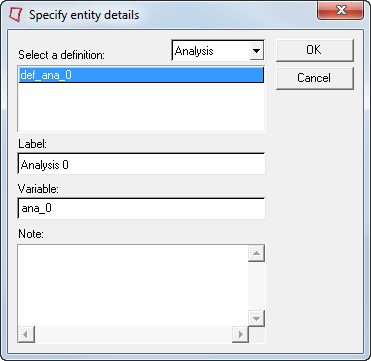

*DefineAnalysis(ana_def_name, arg_1,arg_2, ..., arg_n)ana_def_nameThe variable name of the analysis definition which will be used while instantiating the analysis.arg_1,arg_2...arg_nA list of arguments passed to the analysis definition as attachments.

| Reference Numbers | System Instantiation with Definition |

|---|---|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| Variable | Relationship |

|---|---|

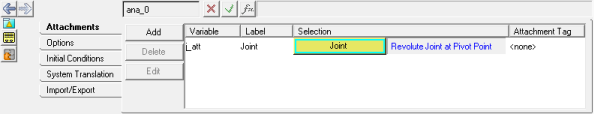

j_joint_att |

The varname of the attachment, declared in the *Attachment() statement (line 4) in the analysis definition file, appears as an argument in the *DefineAnalysis() statement (line 3). A motion is applied on this joint using the *Motion() statement (line 6). |

ana_def |

The varname of the analysis definition is specified in the *DefineAnalysis() statement (line 3). The analysis definition is used by ana1 in the *Analysis() statement (line 2). |

Create the Analysis Definition File

In this step you will create the analysis definition file.

- Use the following function expression to create the impulse torque about the x

axis:

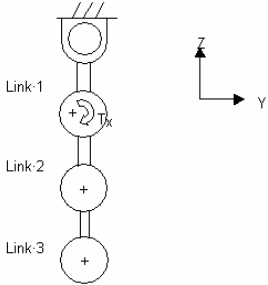

Tx = step(TIME,.3, 0, .31, 10) + step(TIME, .31, 0, .32, -10) - Apply this torque to estimate the natural frequencies of the triple pendulum

model shown in Figure 1:

Figure 1. Schematic representation of a triple pendulum in stable equilibrium

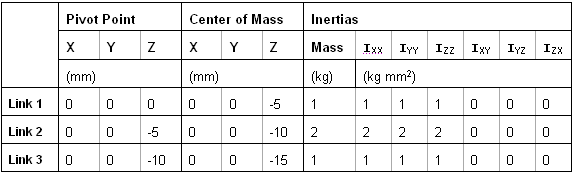

Figure 2. Properties table for the triple pendulum

*Attachment()

*ActionReactionForce()

*SetForce()

*Output() Instantiate the Analysis in a Model

In this step, you will instantiate the analysis in the triple pendulum model.