Apply Thickness to Midsurface

Use the Map Thickness tool to apply thickness values to shell elements on midsurfaced geometry.

The thickness will be assigned on the midmesh either on node card, element card, nodal thickness on element card or also as properties on elements depending on the solver interface you are using.

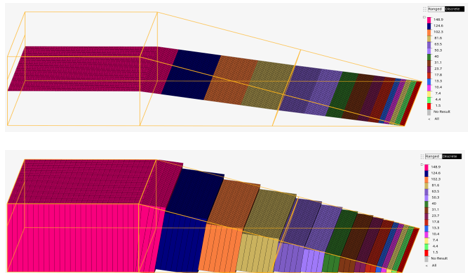

Figure 2.

Options for Map Thickness

Access the following options by clicking ![]() on the

Elements ribbon: Map Thickness tool

guide bar.

on the

Elements ribbon: Map Thickness tool

guide bar.

Define Thickness Options

- Minimum thickness/Maximum thickness

- Define a thickness to assign calculated thicknesses.

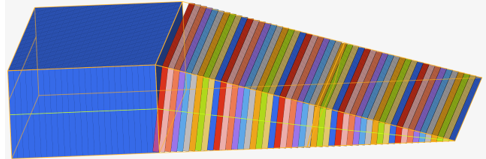

- Assign offset to elements/sections

- To assign an offset value to elements if they are not in the middle of

the selected geometry, select the Assign offset to

elements/sections checkbox.

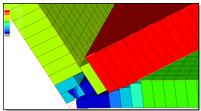

Figure 3. Element Offset Off

Figure 4. Element Offset On - Group elements by thickness interval

-

- Automatic Method

- Groups elements with similar thicknesses together, and assigns an average thickness to the groups based on the “Factor of thickness” interval range input.

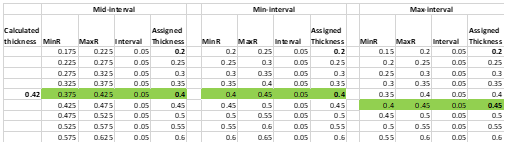

- Method Fixed Interval

- Control thickness properties at constant intervals.

- Merge isolated elements with adjacent groups

- Merges isolated elements into adjacent groups. The tolerance factor is used to determine if the element is going to be regrouped by “Thickness Variation Factor”. Range (0, 1.0). For example, if the value is 0.2, elements can only be regrouped if the percentage change in thickness is going to be less than 20%.

- Thickness precision

- Round the thickness values up or down to have the same number of decimal digits as the input value in the Maximum thickness range interval field. There are three modes available. Automatic determines an optimal truncation.

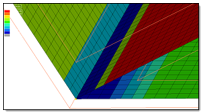

- Scaling at corners [0,10]

- Enter a scaling factor to use when interpolating thickness values near

t-junctions or corners. A value less than 1 will result in linear

decrease in the thickness values nearer to the junction/corners. A value

of zero will result in an approximate mass-conserved thickness

estimation. When equal to 1, the thickness is extrapolated /

interpolated without any scaling. When greater than 1, the thickness

will increase as you go closer to the junction.

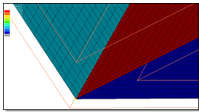

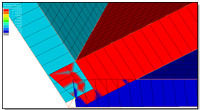

Figure 8. Scaling = 0, Thickness Contour Applied, Traditional Element Visualization

Figure 9. Scaling = 0, Thickness Contour Applied, 2D Detailed Element Representation

Figure 10. Scaling = 1, Thickness Contour Applied, Traditional Element Visualization

Figure 11. Scaling = 1, Thickness Contour Applied, 2D Detailed Element Representation

to define map

thickness options.

to define map

thickness options.