Seam Welds

Create Seam Welds in SimSolid.

Purpose

- Learn how to create welds from solids, group welds, master welds, and welds from lines/edges.

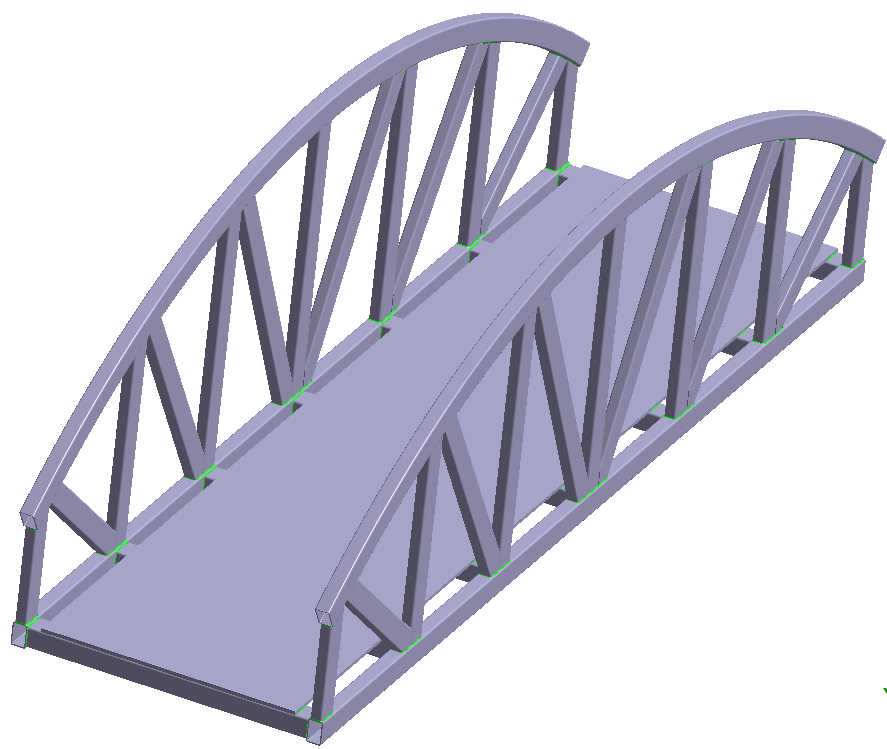

Model Description

- Foot Bridge_solid_parts.x_b

- SeamWeldLines.xml

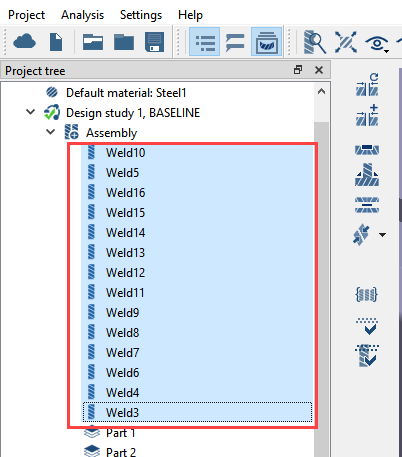

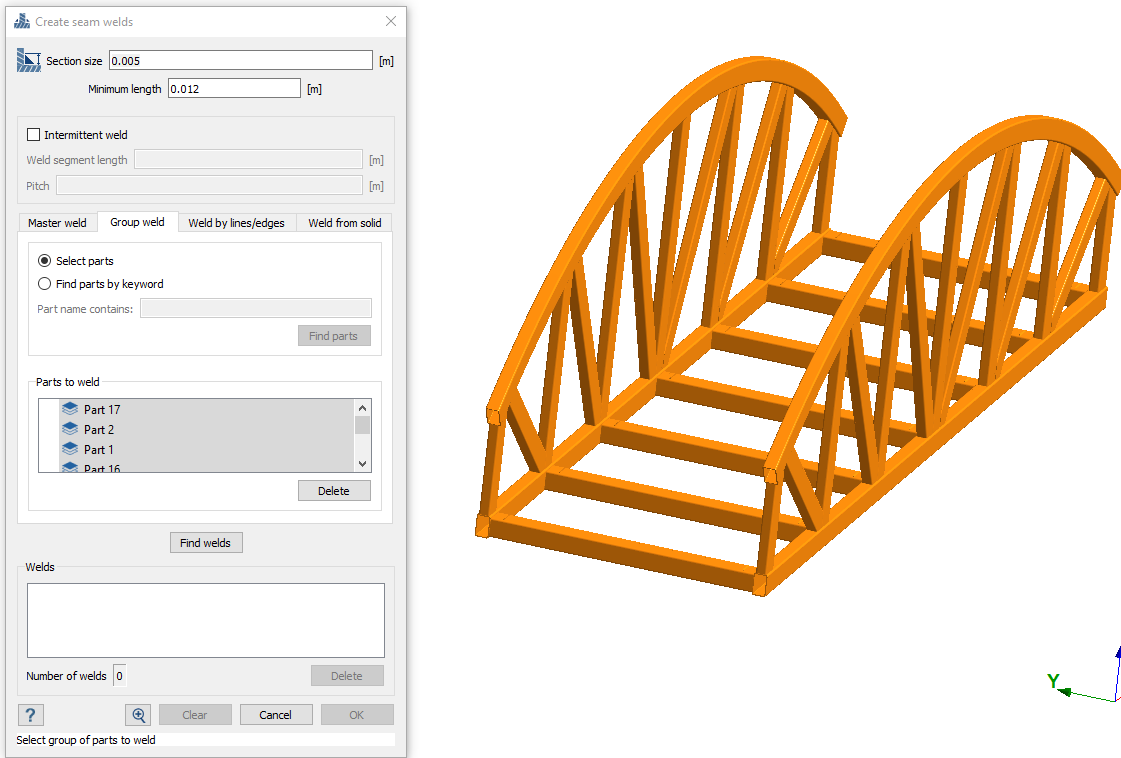

Figure 1.

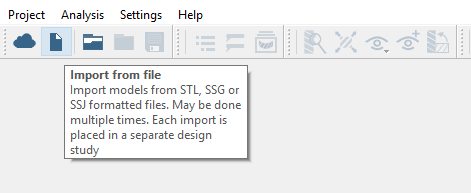

Import Geometry

Import model geometry into SimSolid.

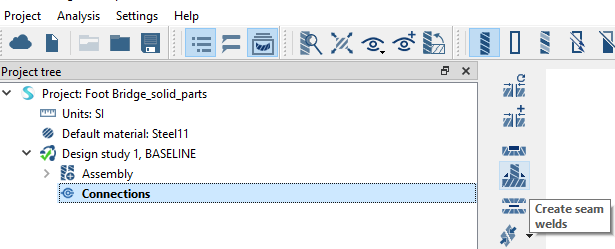

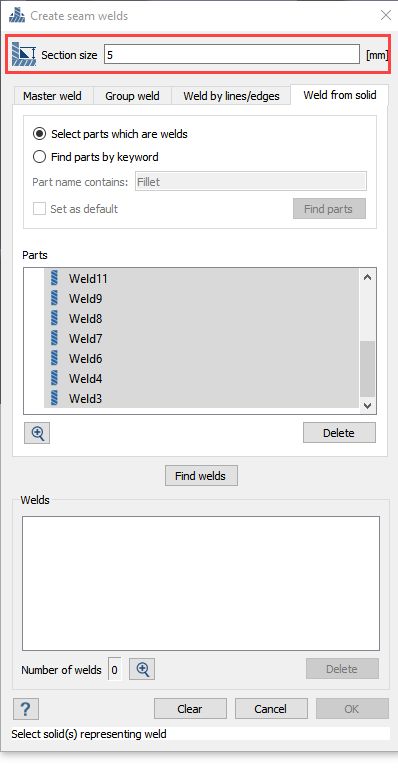

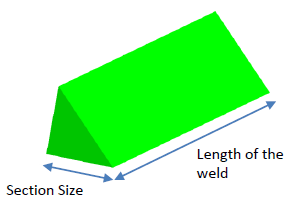

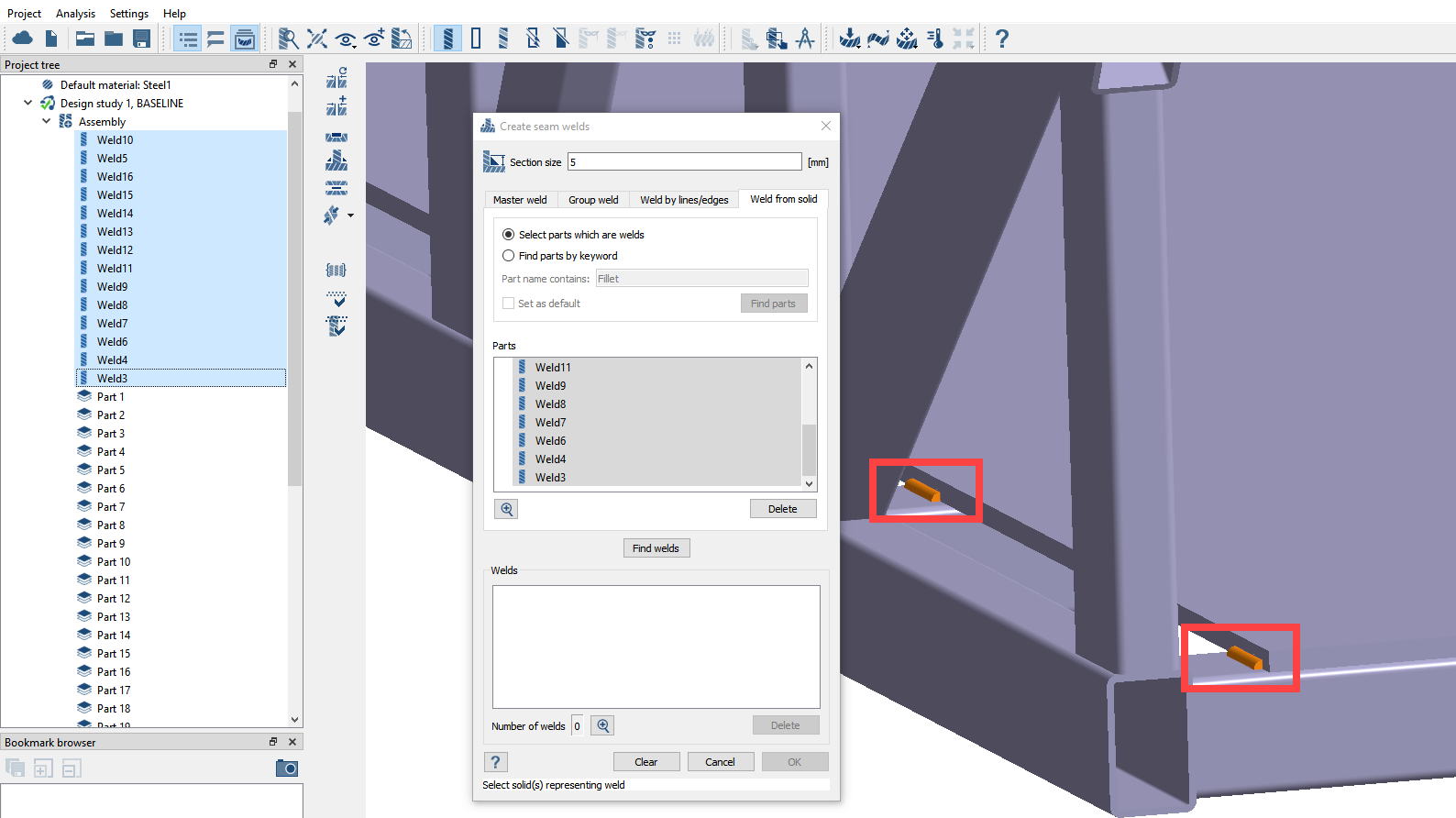

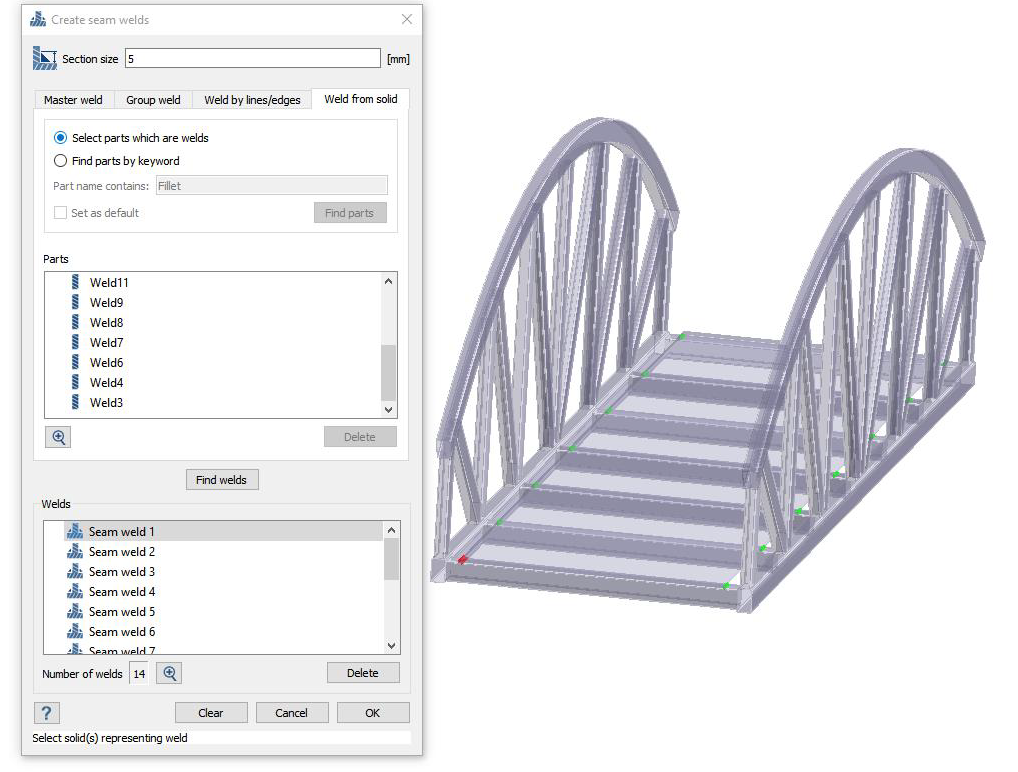

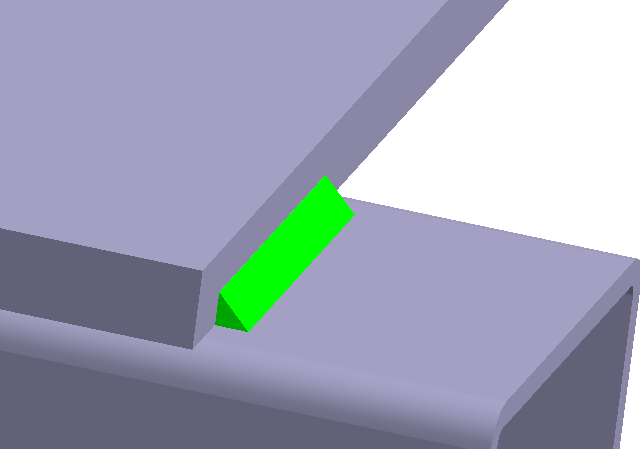

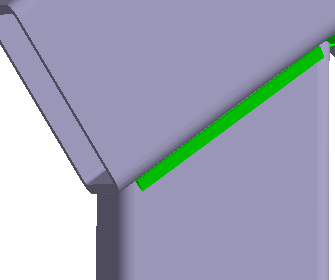

Create Seam Welds from Solids

Convert solids into seam welds.

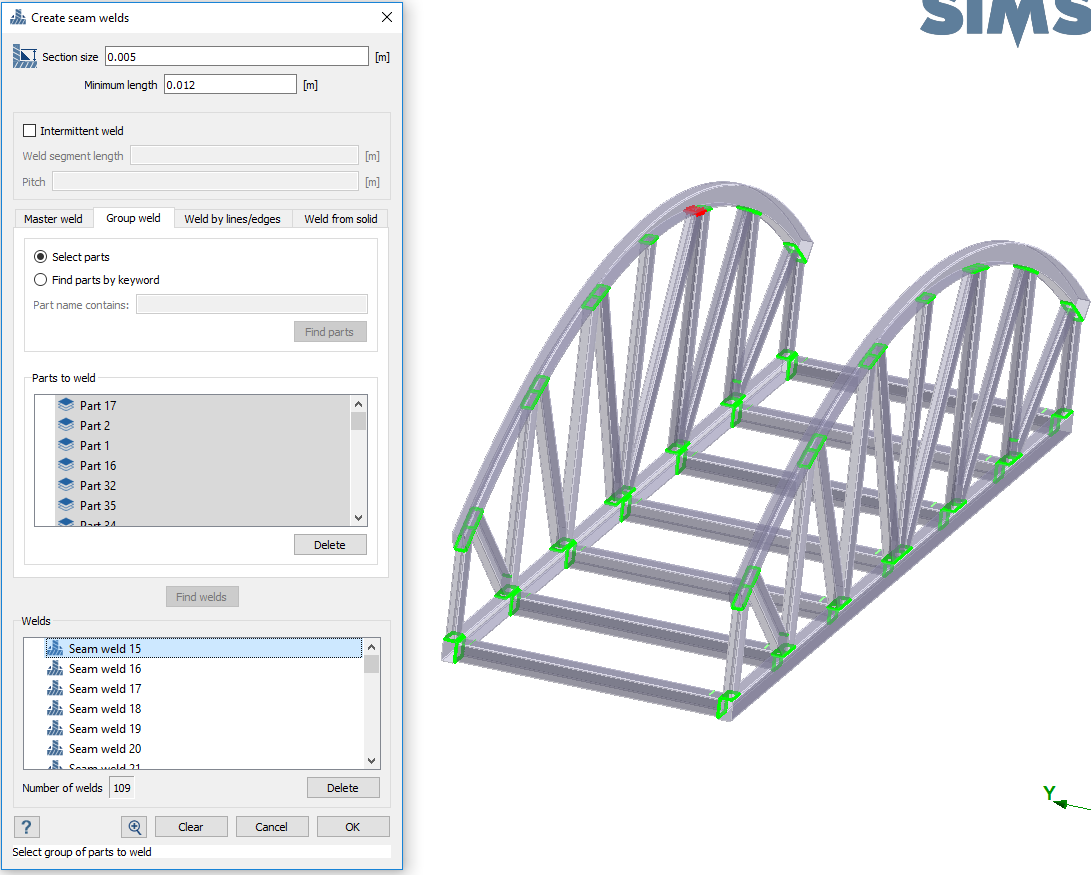

Create Welds Using Group Welds

Use the Group Welds option to create seam welds.

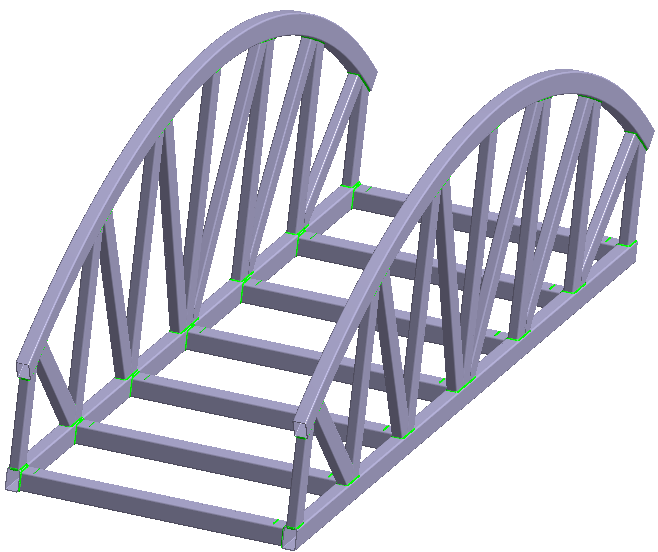

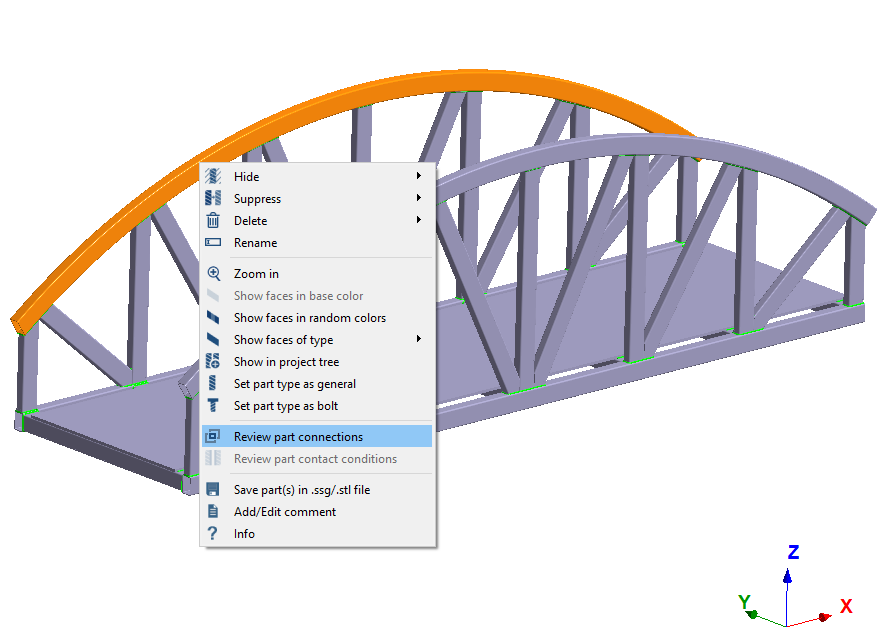

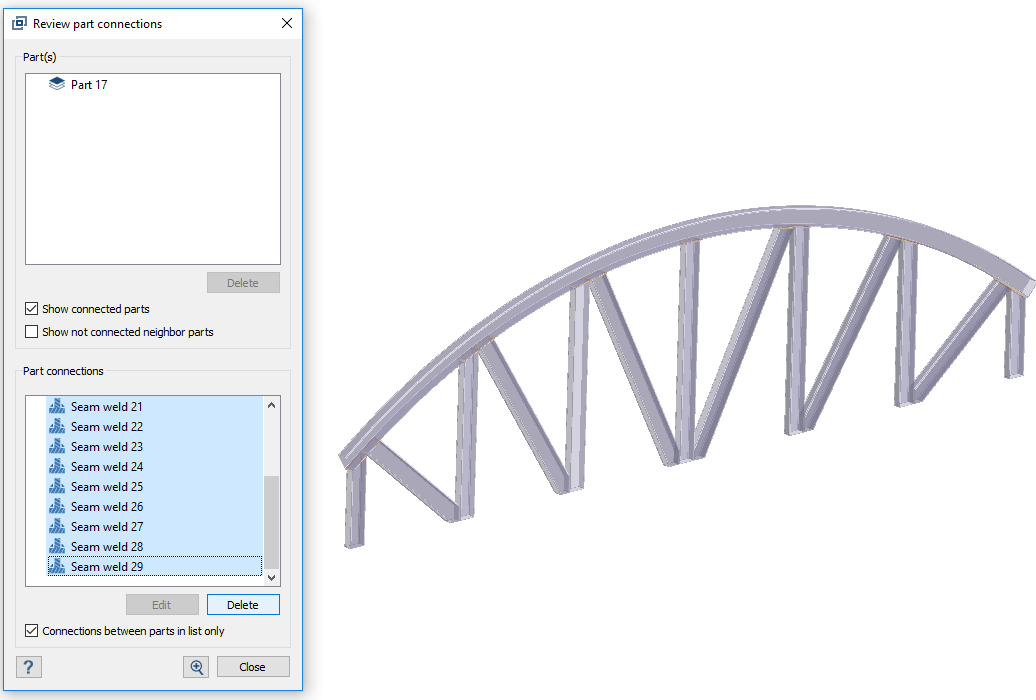

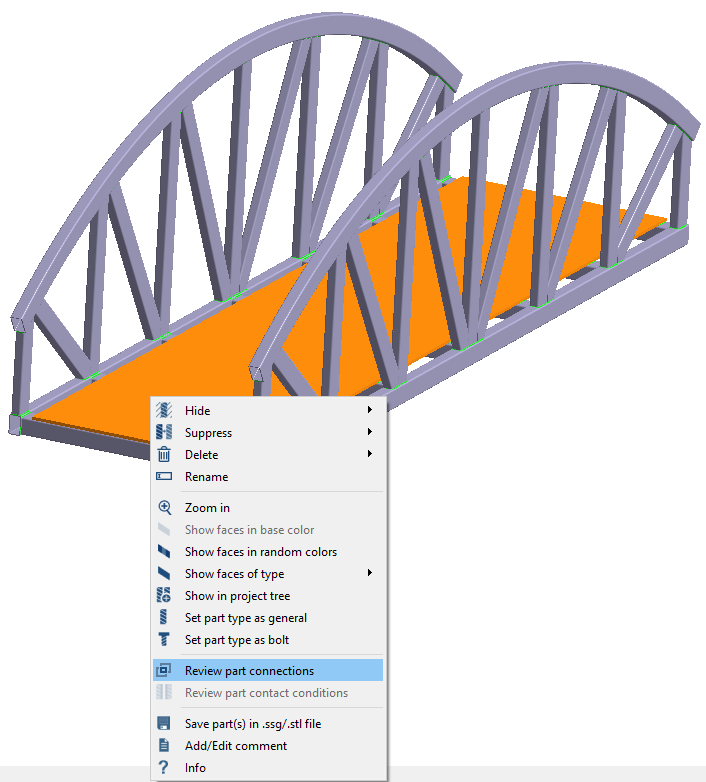

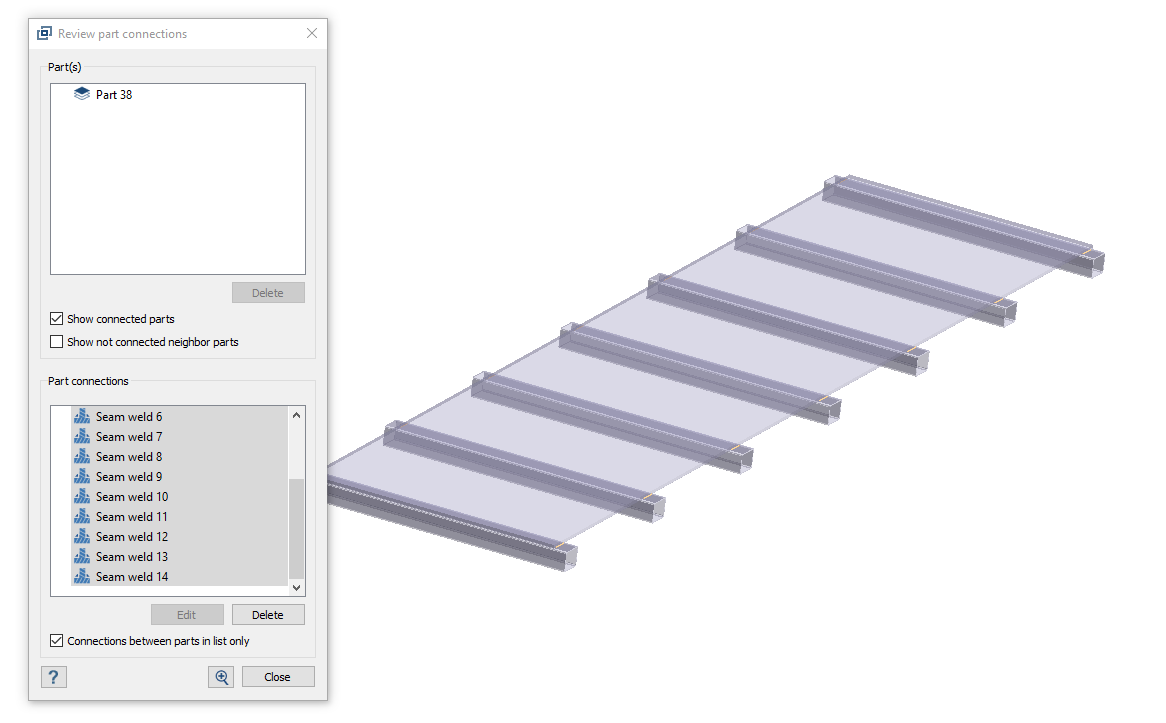

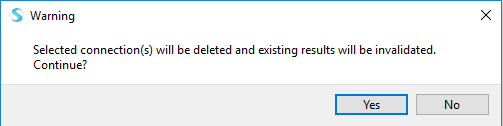

Review Connections and Delete Seam Welds

Review part connections and delete seam welds associated with a part.

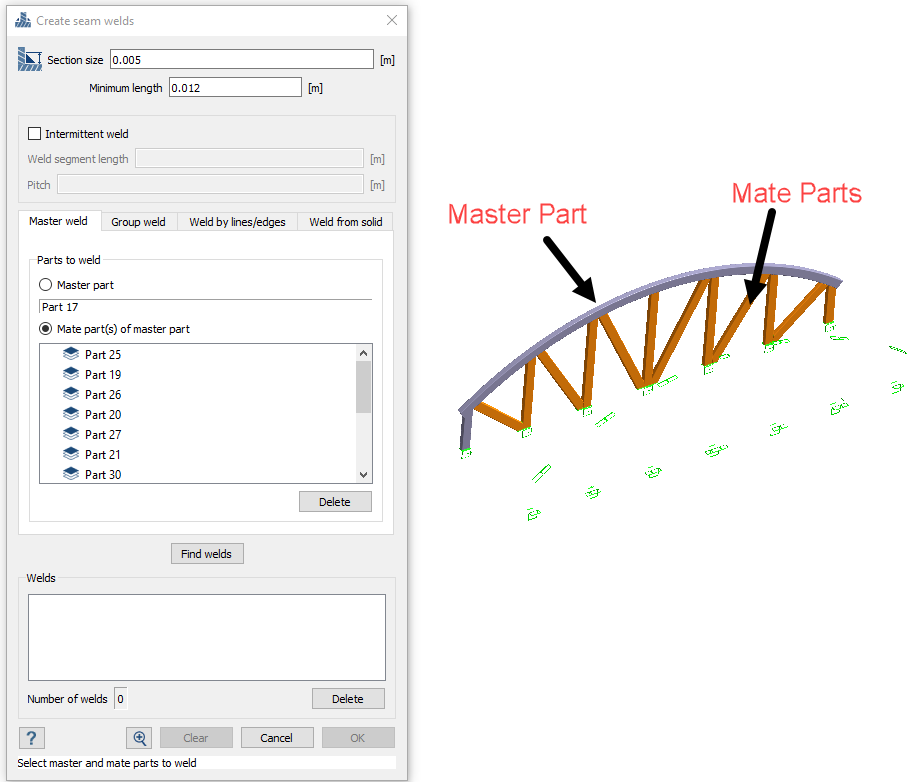

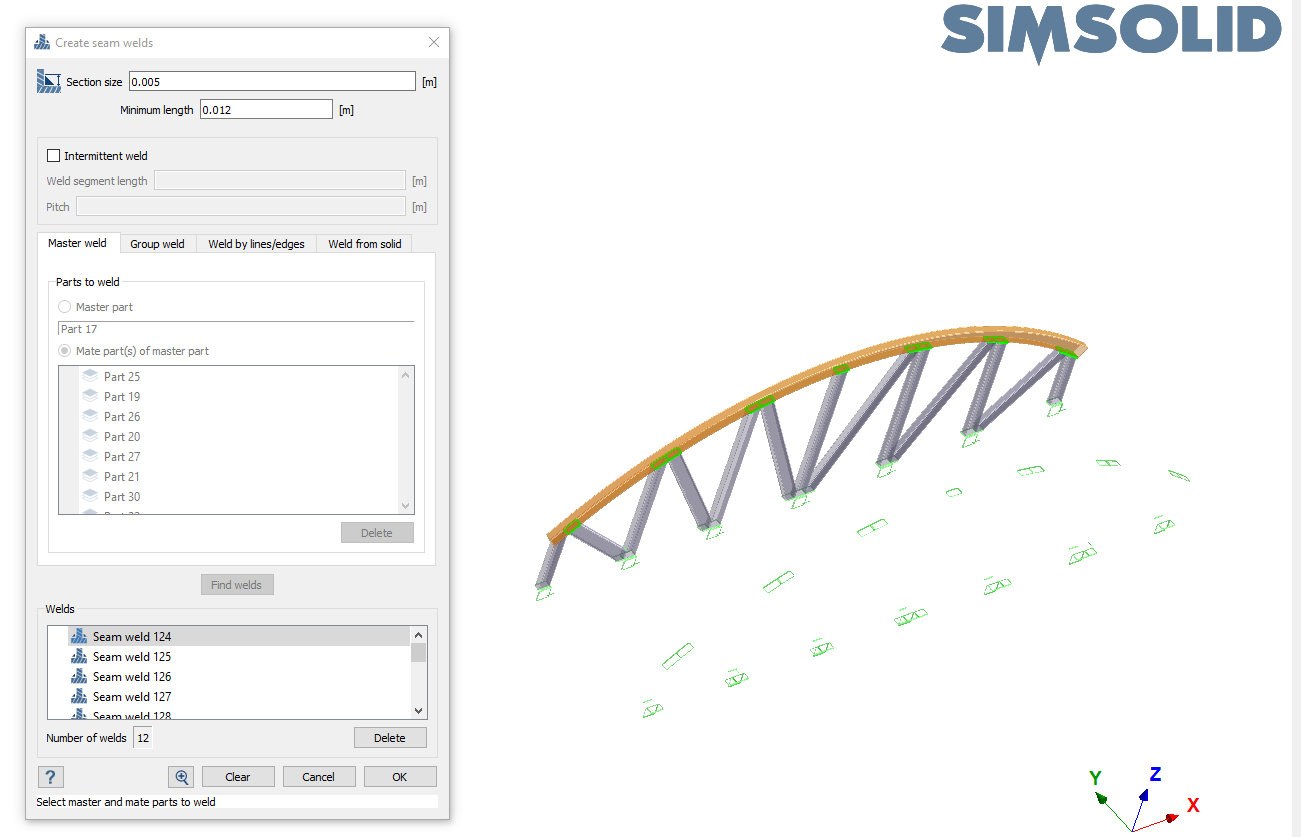

Create Welds Using Master Welds

Use the Master Welds option to create seam welds.

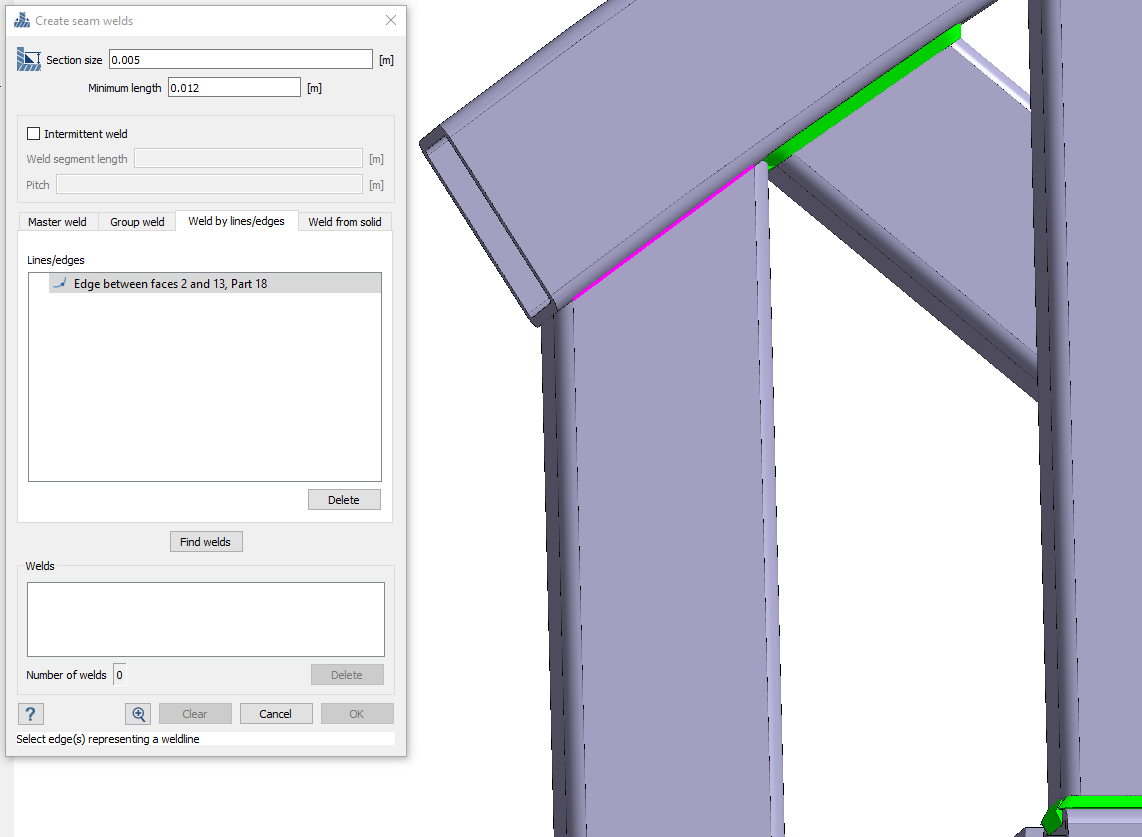

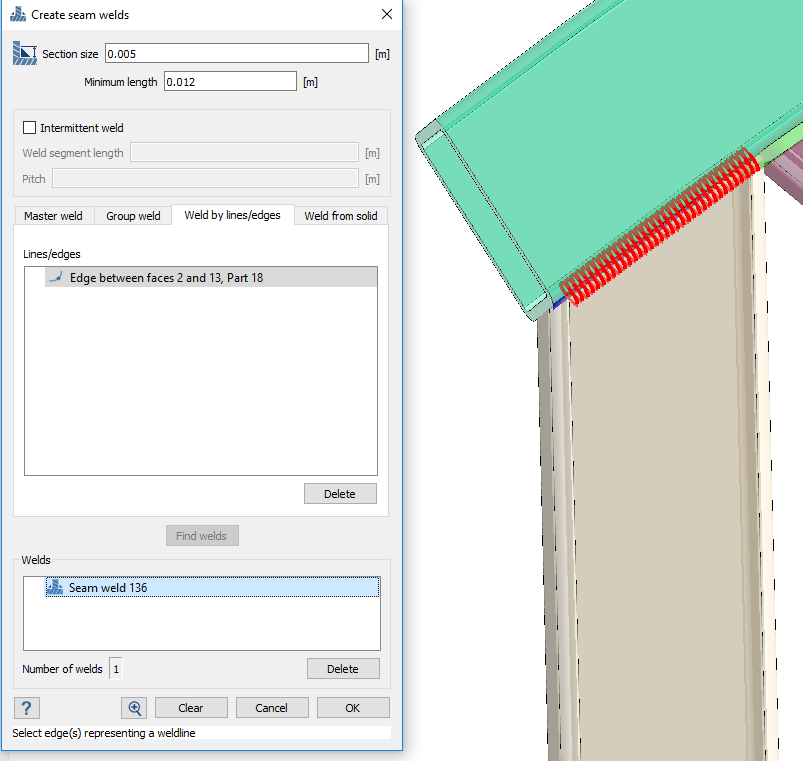

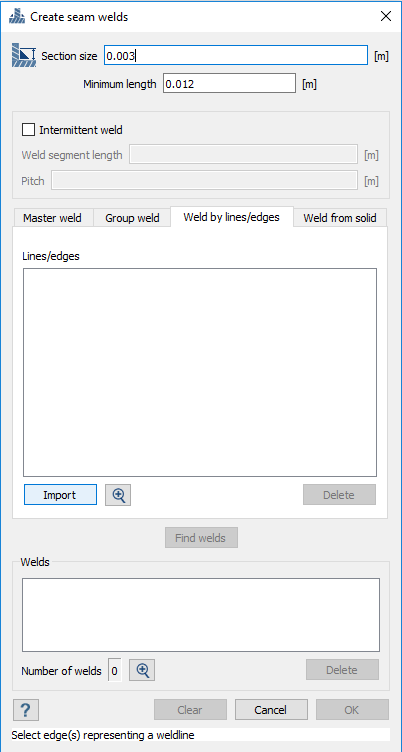

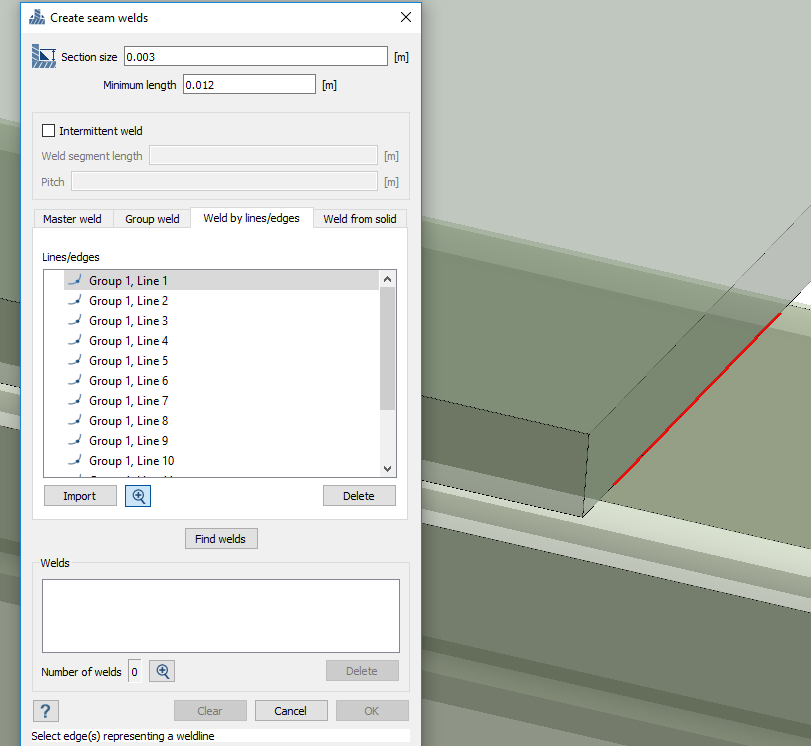

Create Welds Using Lines/Edges

Use lines/edges to create seam welds.

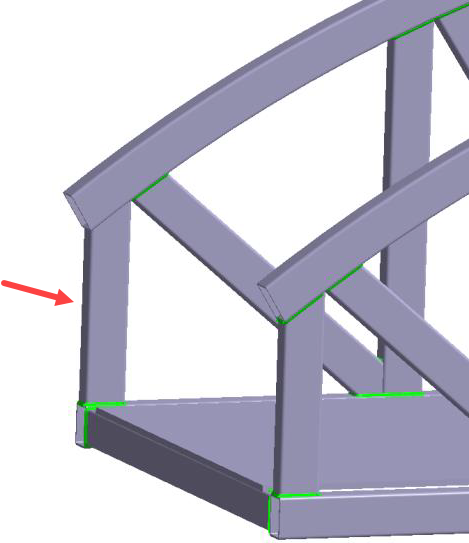

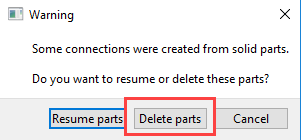

Review Seam Welds

Review seam welds and delete welds created from solids.

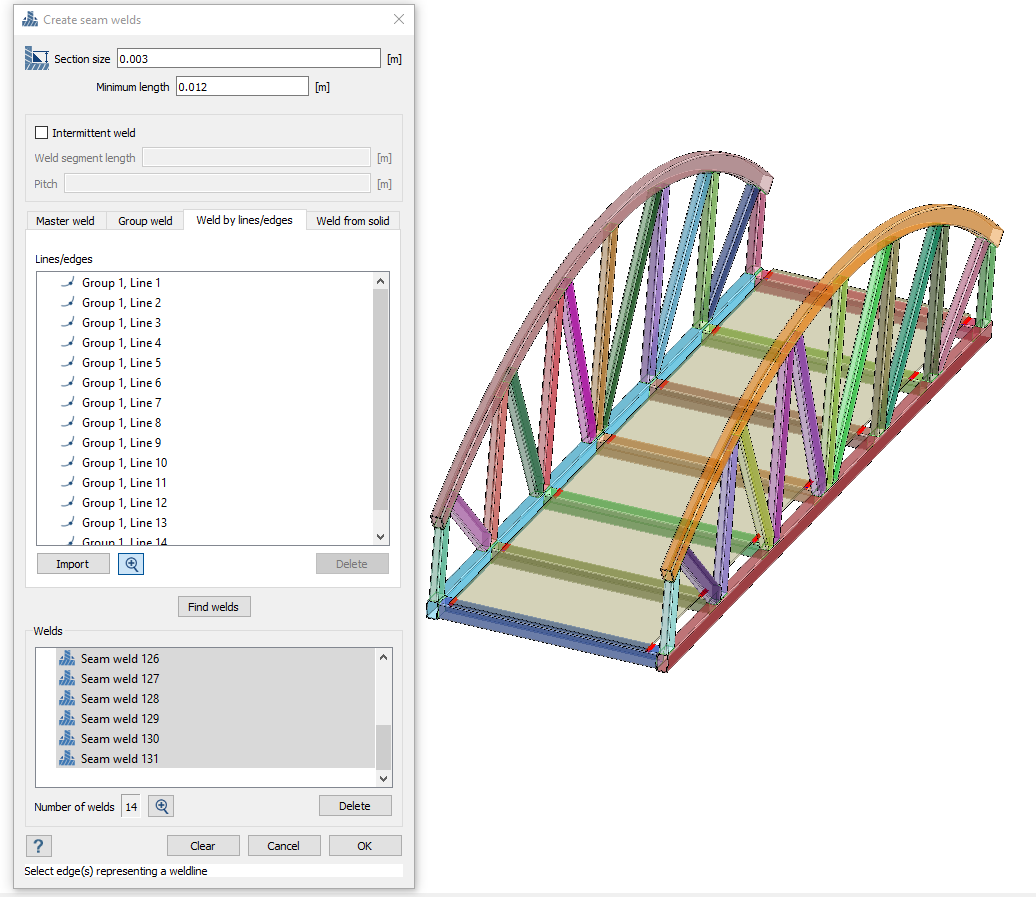

Create Seam Welds from Imported Lines

Import lines and create seam welds from those lines.

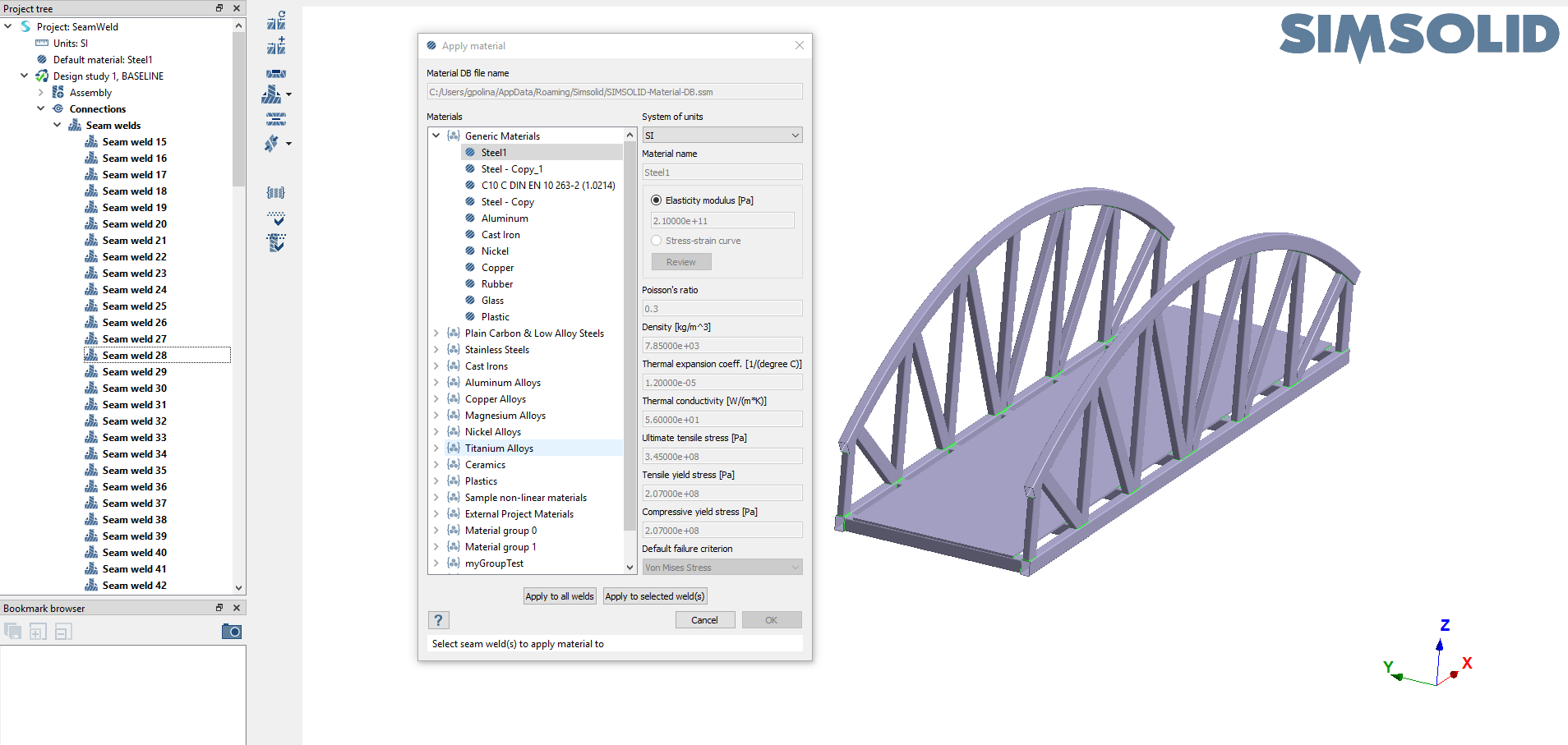

Add Material

Add material to seam welds.