Static Structural Analysis - Pullup Bar

Perform a static structural analysis of a pullup bar assembly.

Purpose

- Learn how SimSolid works

- Create a comparison for SimSolid's workflow and results with those obtained with traditional FEA.

Model Description

- 2 load cases of 750N (168 lbf) total load on different handle locations

- 2 different design configurations with varying support brackets

- Pullup bar V1.x_t

- Pullup bar V2.x_t

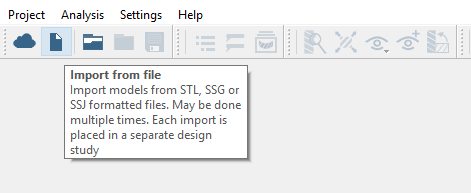

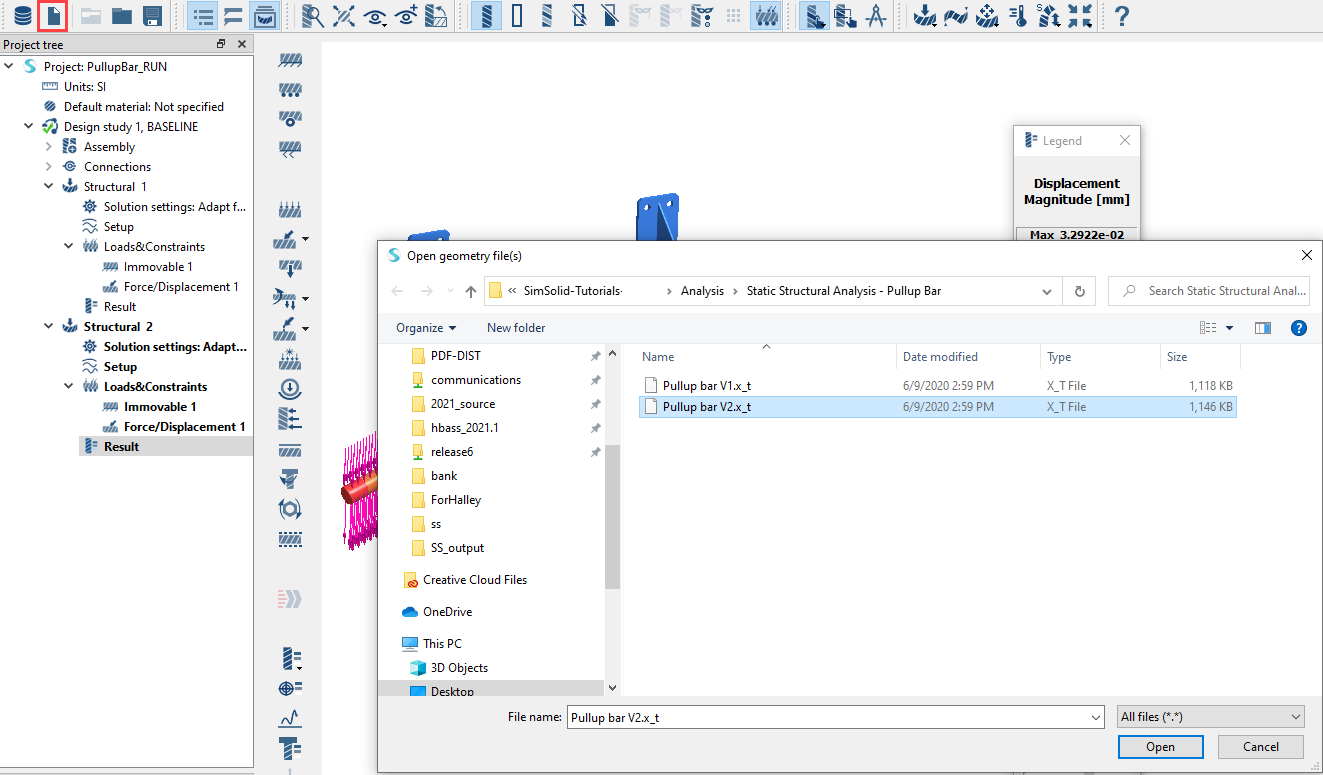

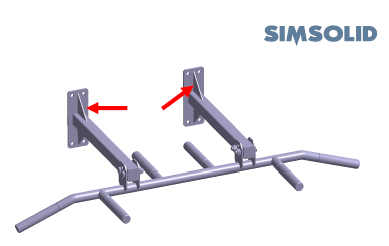

Figure 1.

Figure 1. Import Geometry

Import model geometry into SimSolid.

Create Connections

Specify gap and penetration tolerances to create automatic connections.

Assign Materials

Apply materials to all parts in the assembly.

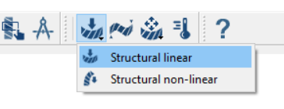

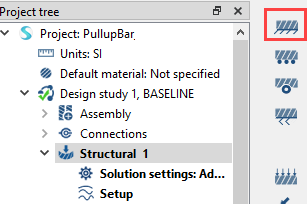

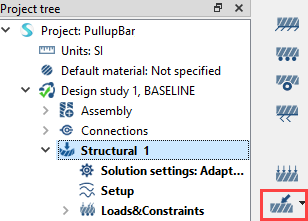

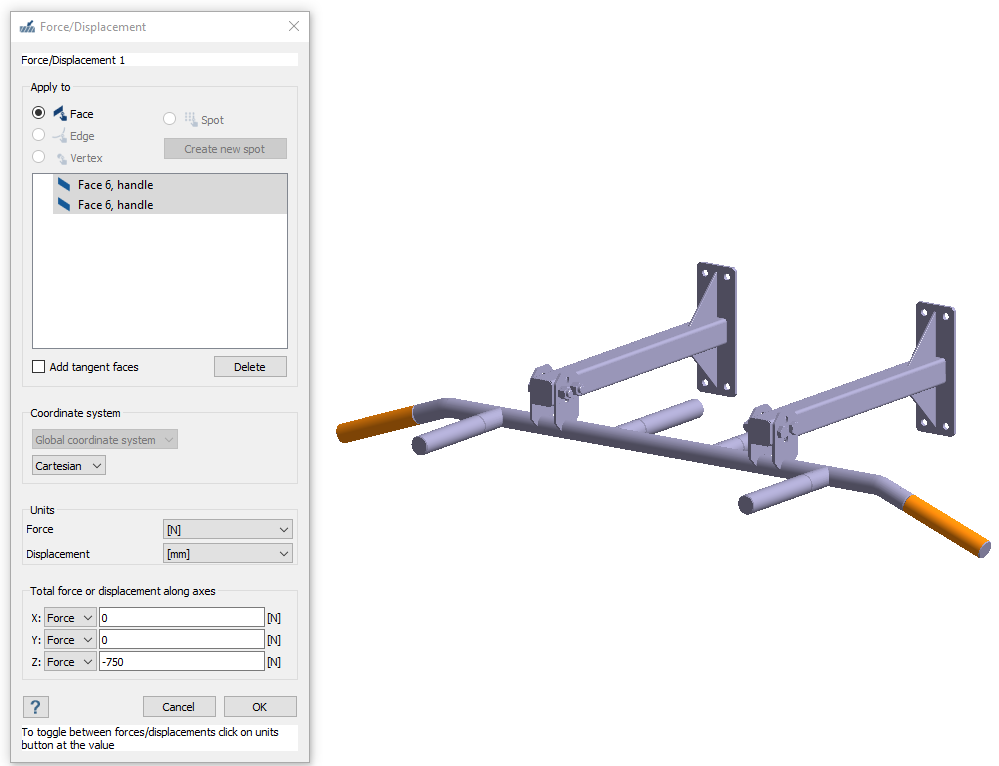

Create Structural Linear Analysis

Create a structural linear analysis with immovable constraints and a handlebar load.

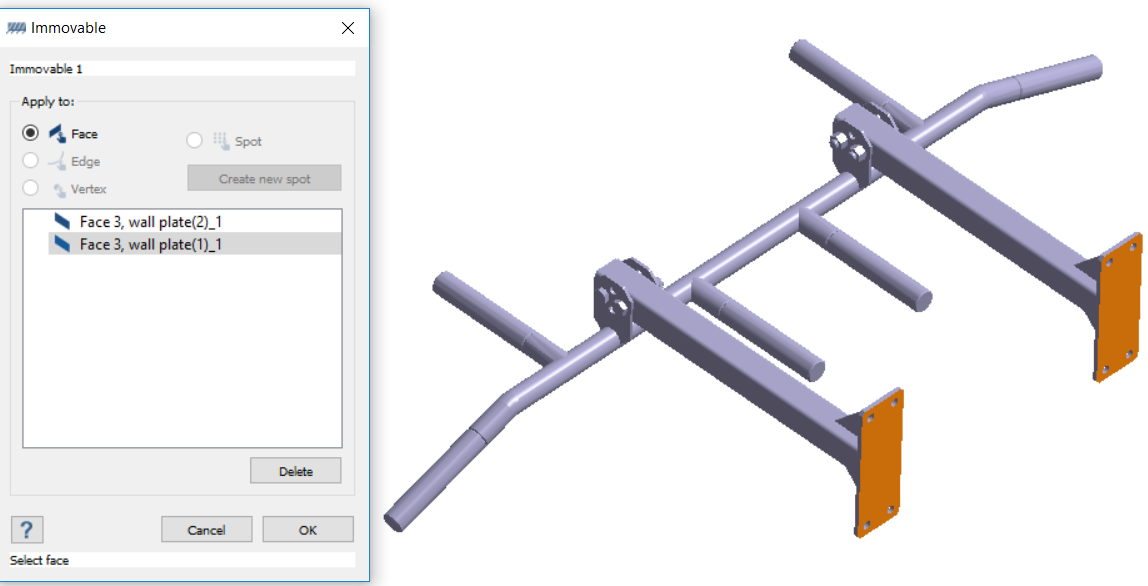

Create Immovable Support

Create immovable supports on the wall faces in the pullup bar model.

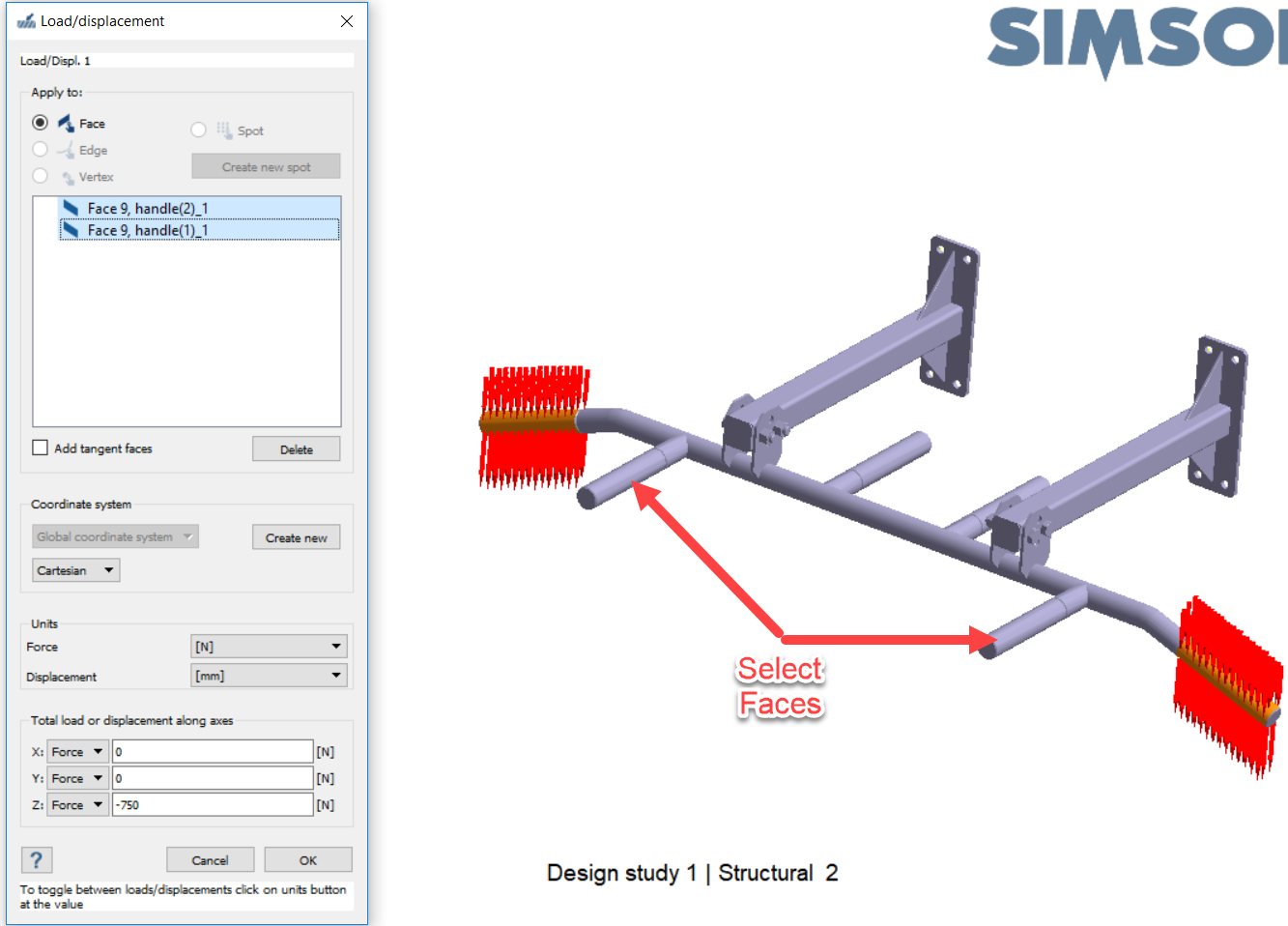

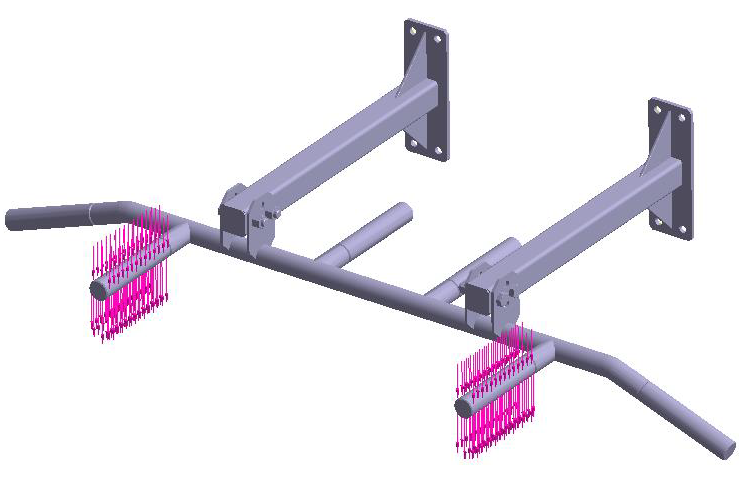

Create Force Loads

Create handlebar loads on the pullup bar model.

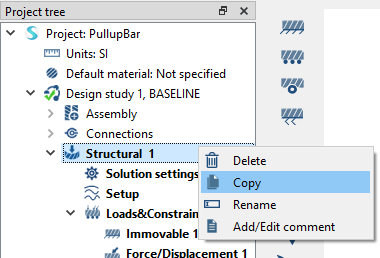

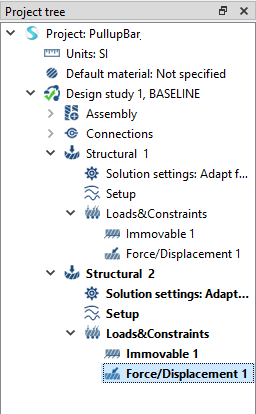

Create Second Structural Linear Analysis

Create a copy of an analysis and edit loads.

Run Design Study

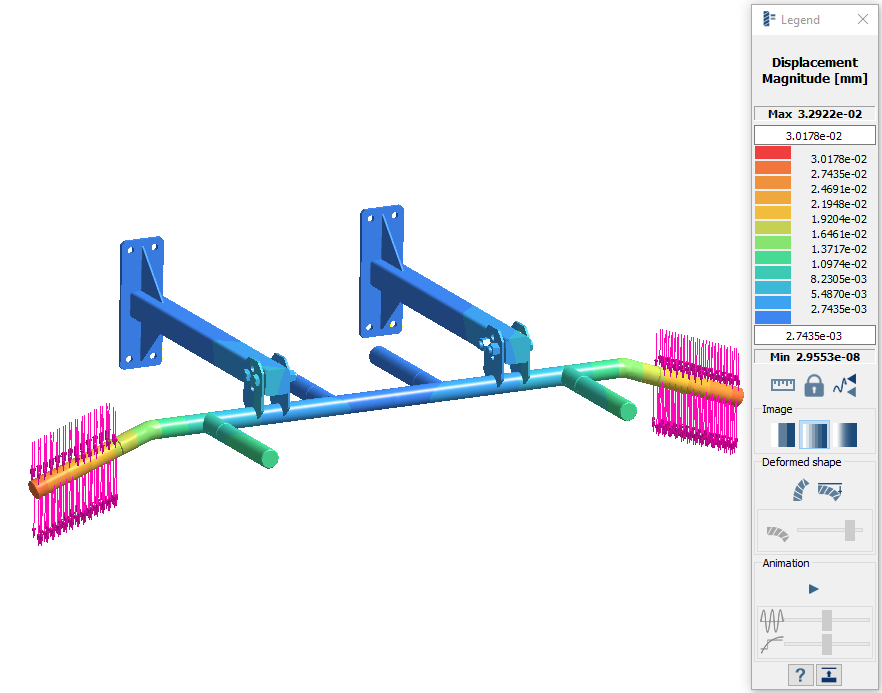

Solve all analyses in the design study.

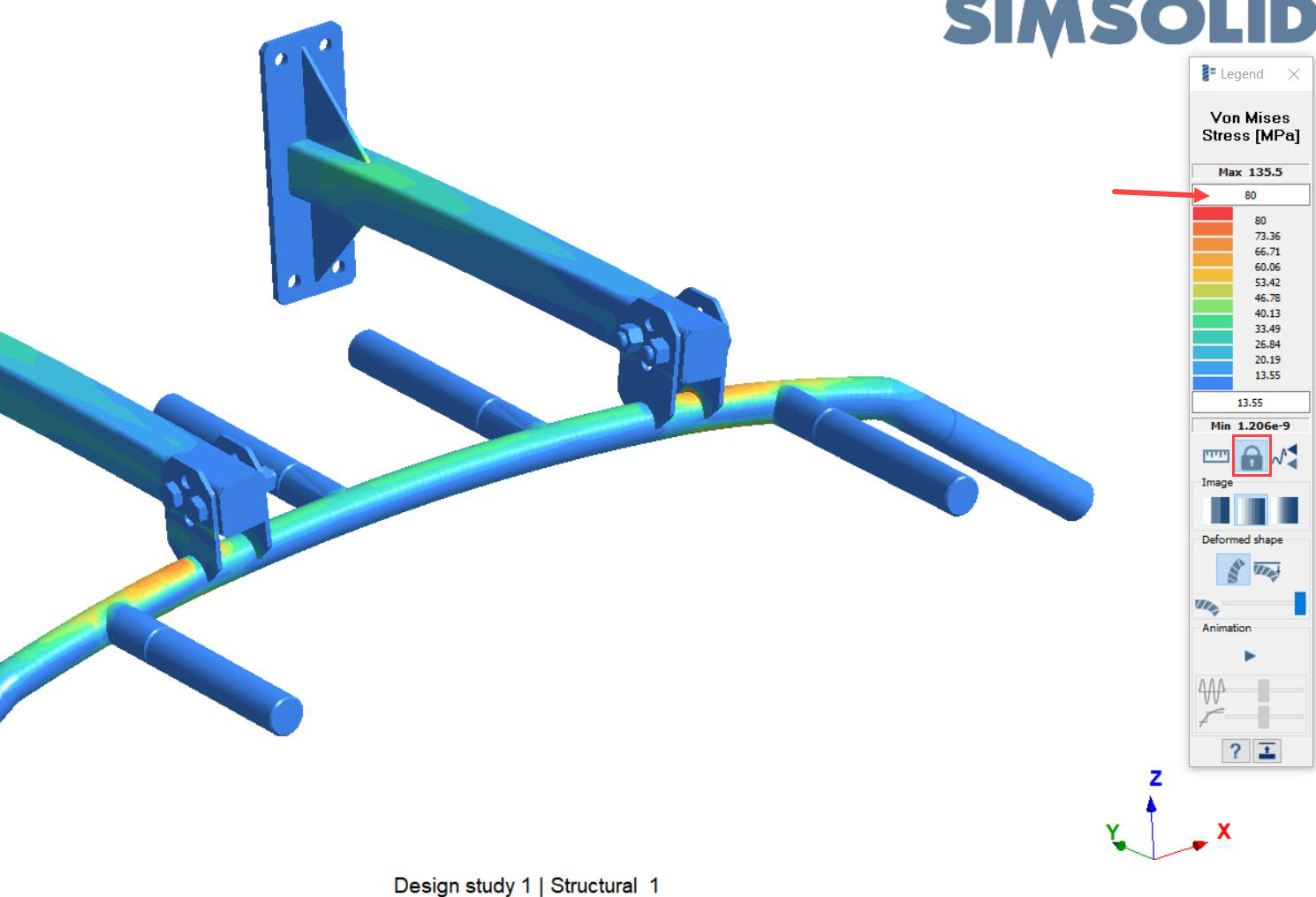

Compare Results with Bookmarks

View results from analysis and create results images/animations.

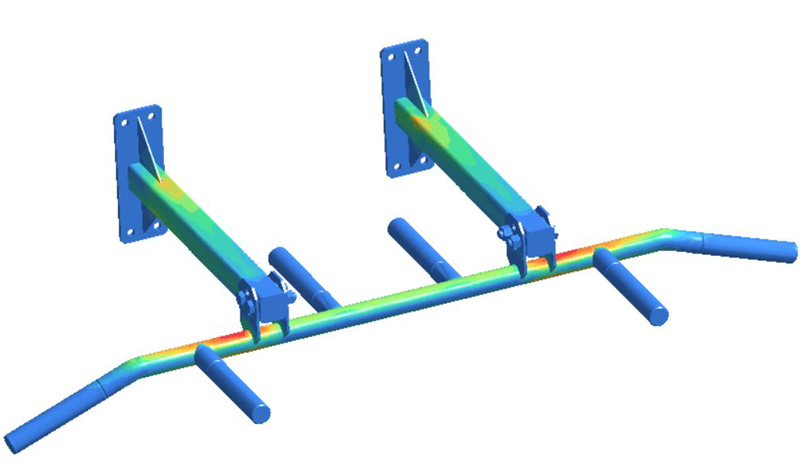

Create Second Design Study

In your project, create a second design study with new geometry.

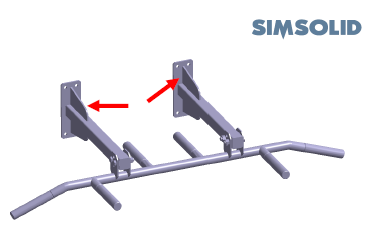

Figure 14.

Figure 15. Design Study 1

Figure 16. Design Study 2

Add Connections for New Parts

Create connections for new parts in the second Design Study.

- Close the part overlap warning and review dialog.

- In the Add connections for new parts dialog, specify gap and penetration tolerances as 1.

- For Connection resolution, select Increased.

- Click OK.

Assign Materials

Apply materials to all parts in the assembly.

Run Design Study

Solve all analyses in the design study.

Compare Results

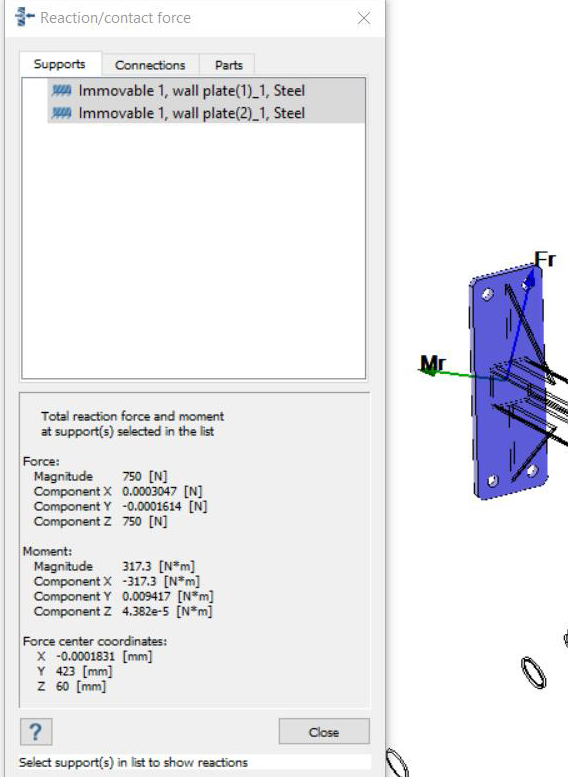

View Reaction Forces

View reaction forces on selected parts of the assembly.

Compare with Traditional FEA

Run the same analysis using your existing traditional FEA application.

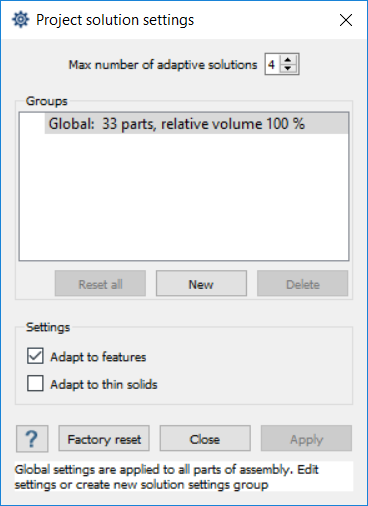

Refine Solution Settings

Adjust SimSolid's solution settings for specialized analyses.