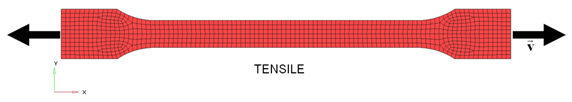

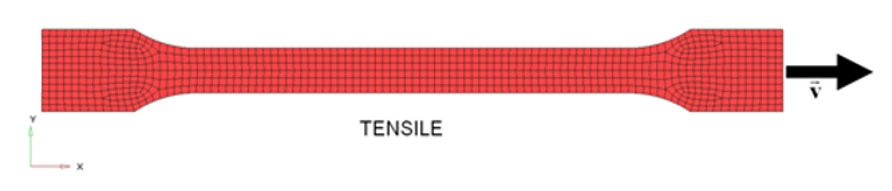

RD-T: 3000 Tensile Test Setup

This tutorial demonstrates how to simulate a uniaxial tensile test using a quarter size mesh with symmetric boundary conditions.

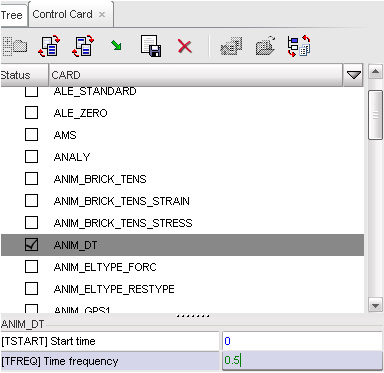

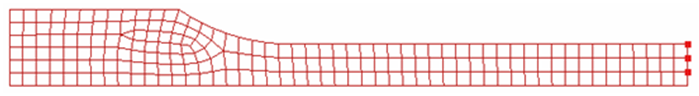

Figure 1.

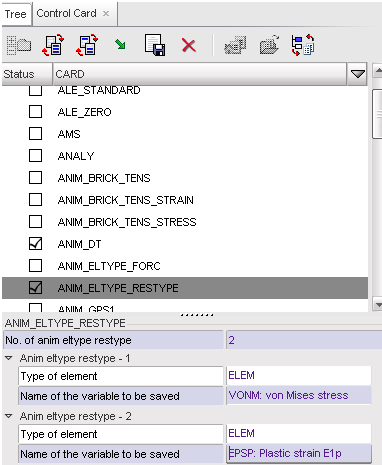

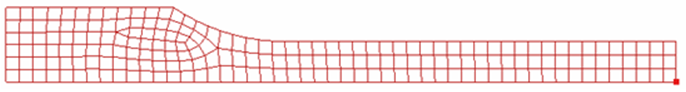

Figure 2.

- UNITS: Length (mm), Time (ms), Mass (kg), Force (kN) and Stress (GPa)

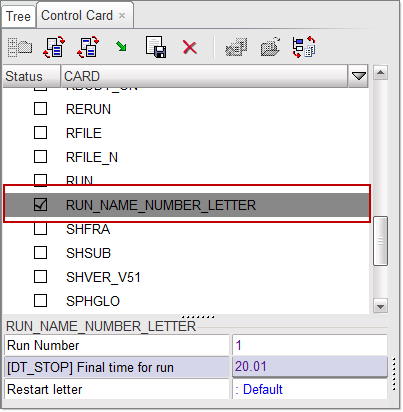

- Simulation time Rootname_0001.rad [0 - 10.]

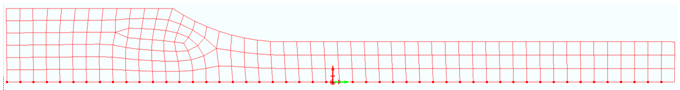

- Boundary Conditions:

- The 3 upper right nodes (TX, RY, and RZ)

- A symmetry boundary condition on all bottom nodes (TY, RX, and RZ)

- At the left side is applied a constant velocity = 1 mm/ms on -X direction.

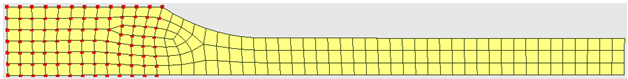

- Tensile test object dimensions = 11 x 100 with a uniform thickness = 1.7 mm

| [Rho_I] Initial density = 2.7e-6 Kg/mm3 |

| [E] Young's modulus = 60.4 GPa |

| [nu] Poisson's ratio = 0.33 |

| [a] Yield stress = 0.09026 GPa |

| [b] Hardening parameter = 0.22313 GPa |

| [n] Hardening exponent = 0.374618 |

| [EPS_max] Failure plastic strain = 0.75 |

| [SIG_max] Maximum stress = 0.175 GPa |

Input file for this tutorial: TENSILE_0000.rad

Create and Assign a Material

Create and Assign a Property

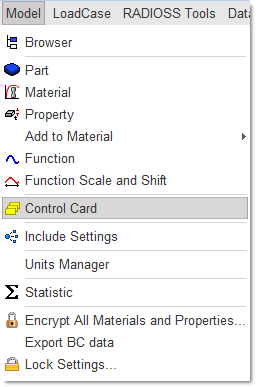

- From the menu bar, select .

- Right-click in the property list and select .

- For Title, enter Pshell.

- For Shell Thickness, enter 1.7.

-

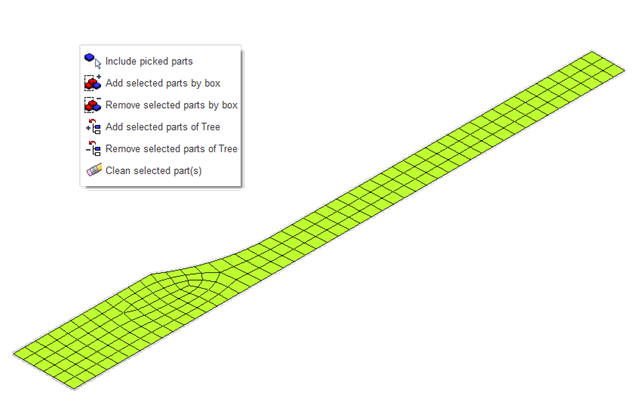

In the bottom of the property window, right-click in the

Support entry box and select the Include

picked parts icon

.

.

- Select the part in the modeling window.

- Right-click to validate the selection.

- Click .

Define Boundary Conditions Representing Symmetry

Define Imposed Velocity

Define a Time History Node

Export the Model

Expected Results

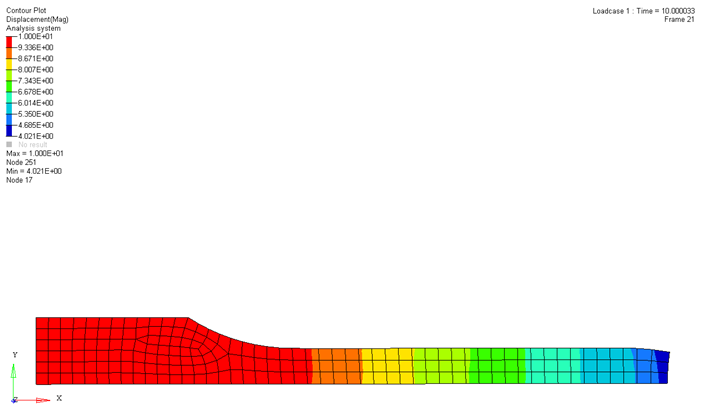

Figure 15. Total Displacement Contour (mm)

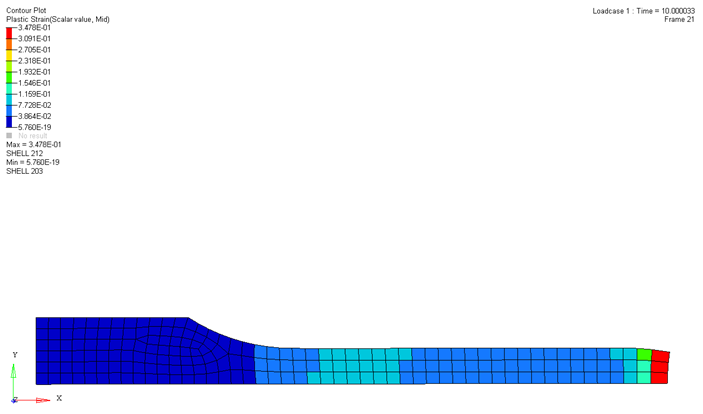

Figure 16. Plastic Strain Contour

to select the

nodes in the

to select the

nodes in the

, to select the nodes in the

, to select the nodes in the

to

add a new row.

to

add a new row.