Radioss材料則では、LAW32、LAW43、LAW72、LAW73、LAW74、LAW78およびLAW93はHILL基準を使用します。

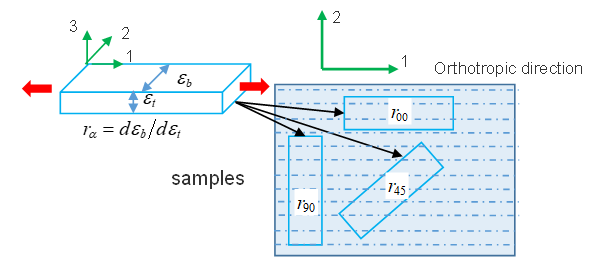

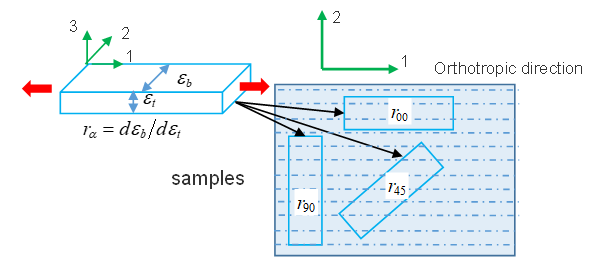

ひずみ比

ランクフォードパラメータ

は、面内の塑性ひずみと厚み方向の塑性ひずみ

との比率です。

(11)

ここで、は、直交異方性方向1に対して成す角度です。

は、直交方向1の異なる角度で切断した異なる試料で測定することができます。は荷重方向が直交方向1に沿った引張試験から測定され、 は荷重が直交方向1に直交する引張試験から測定されます。

ひずみ比は、試料の幅方向のひずみと試料の厚さ方向のひずみとの比です。

図 10.

この場合、HILLパラメータは:

(12)

(13)

(14)

(15)

ここで、

LAW32、LAW43およびLAW73では、HILL基準は:

(16)

|

|

|

|

|

|

これらはすべてランクフォードパラメータ(ひずみ比)を要求し、HILLパラメータはRadiossによって自動的に計算されます。

降伏応力比

LAW93では、使用される降伏応力比は:

(17)

降伏応力比

を得るには2つの荷重ケースでの降伏応力を測定する必要があります。

- 引張試験からの降伏応力

- せん断試験からの降伏せん断応力

LAW93では、パラメータ入力が使用されている場合は初期応力パラメータを基準降伏応力 とします。曲線入力を使用する場合は、曲線からの降伏応力を基準降伏応力 とします。

シェル用の4つのHILLパラメータが

Radiossによって自動的に計算されます。

(18)

(19)

(20)

(21)

LAW74では、降伏応力比

は降伏応力

および

入力と直接使用され、ソリッド用の6つのHILLパラメータが

Radiossによって自動的に計算されます。

|

|

|

|

|

|

シェル要素の場合、、とします。